Drive circuit for reducing motor

A deceleration motor and drive circuit technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., can solve the problems of laborious, single function, inconvenient, etc., achieve automatic forward and reverse rotation function, realize The effect of forward and reverse rotation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical implementation process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

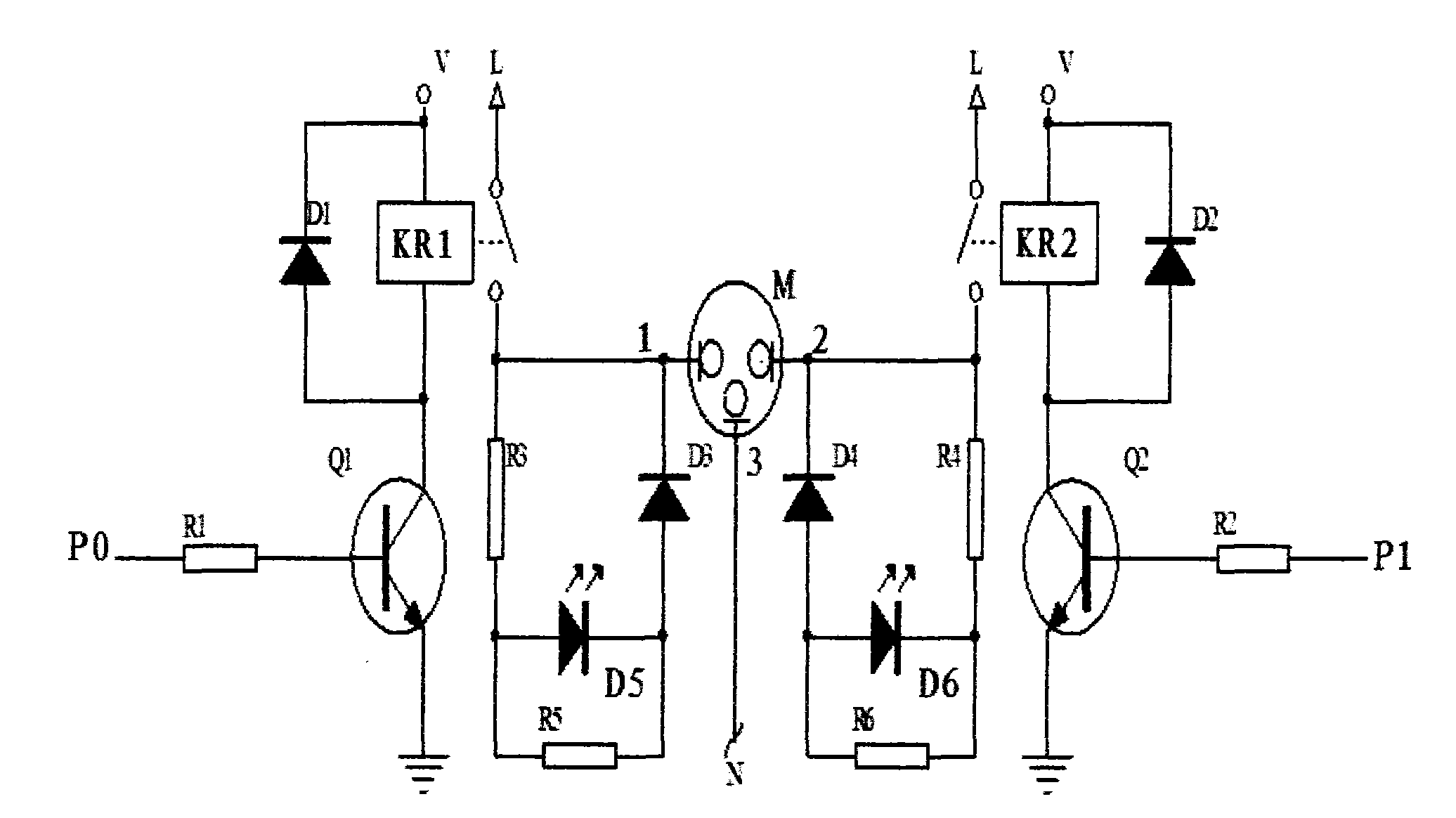

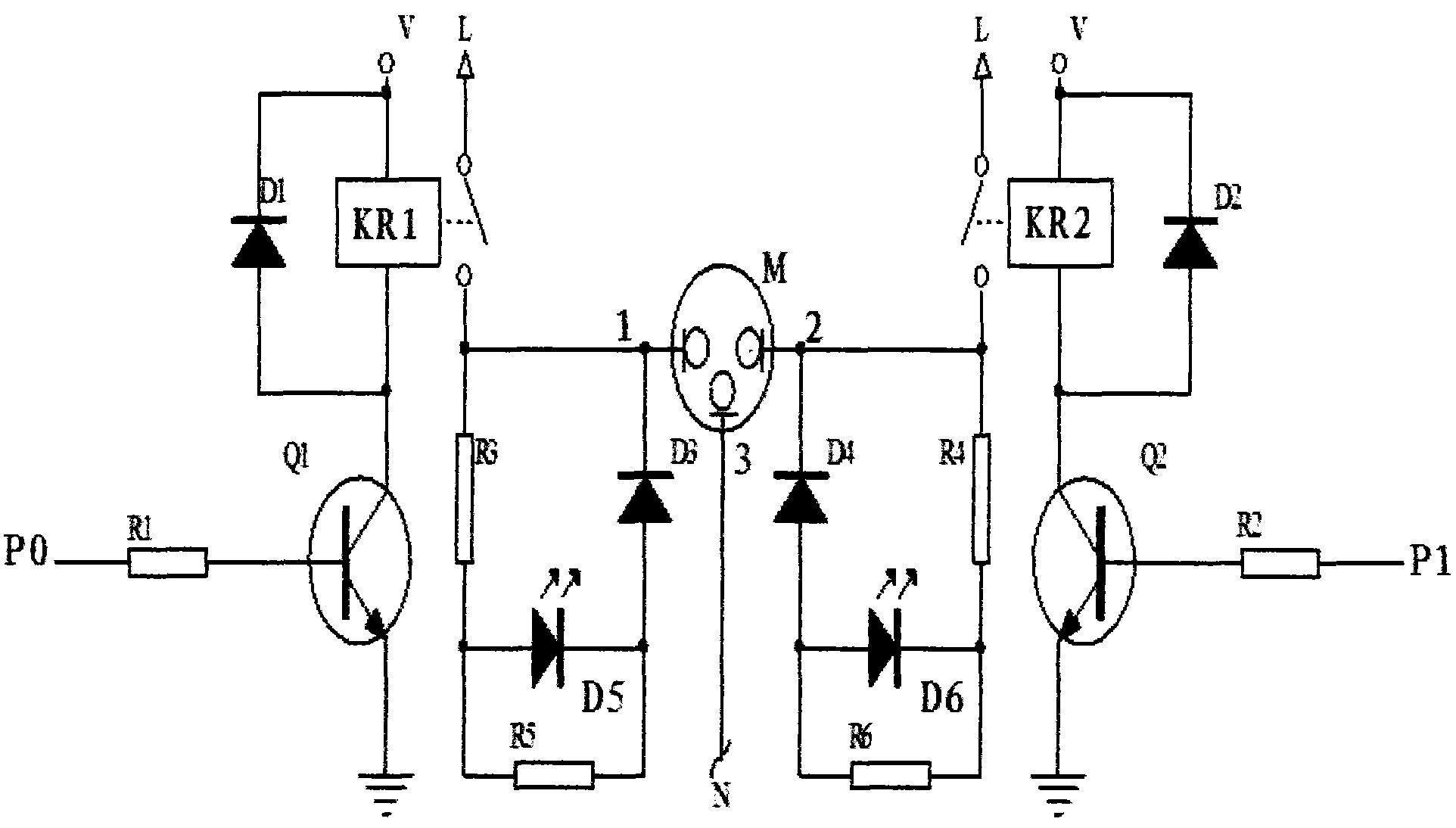

[0024] see figure 1 As shown, a geared motor drive circuit includes a geared motor M, the third input terminal 3 of the geared motor M is connected to the neutral line N, and the first input terminal 1 of the geared motor M is connected to the output of the trigger KR1 One end of the loop, the other end of the output loop of the flip-flop KR1 is connected to the fire line L, one end of the input loop of the flip-flop KR1 is connected to a power supply V, and the other end is connected to the collector of the triode Q1, the The emitter of the triode Q1 is grounded, and the base is connected to the output terminal P0 of a control chip through the resistor R1; the second input terminal 2 of the deceleration motor M is connected to one end of the output circuit of the trigger KR2, and the output terminal of the trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com