Main driving motor hoisting method of roughing mill

A technology of a main drive motor and a hoisting method, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of insufficient hoisting force, high cost, unsafe use, etc. High, load-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

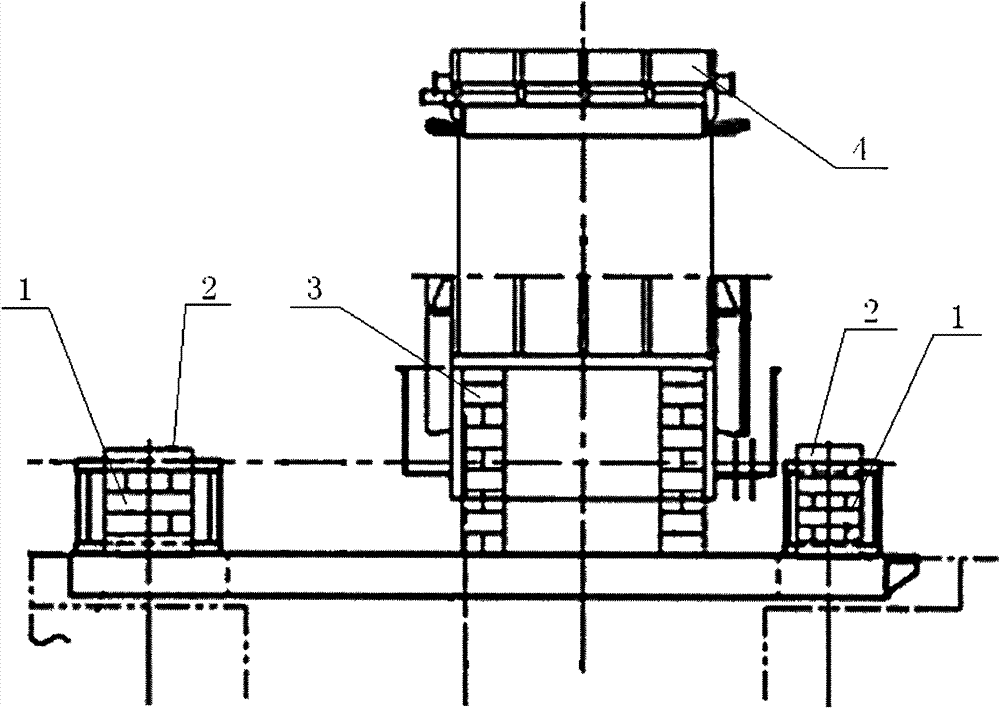

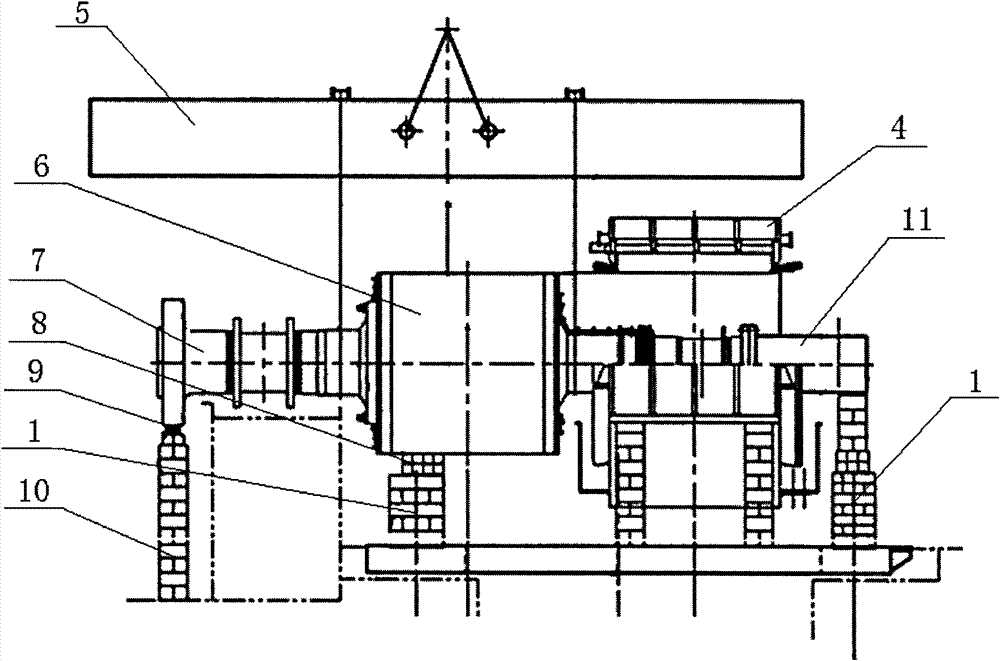

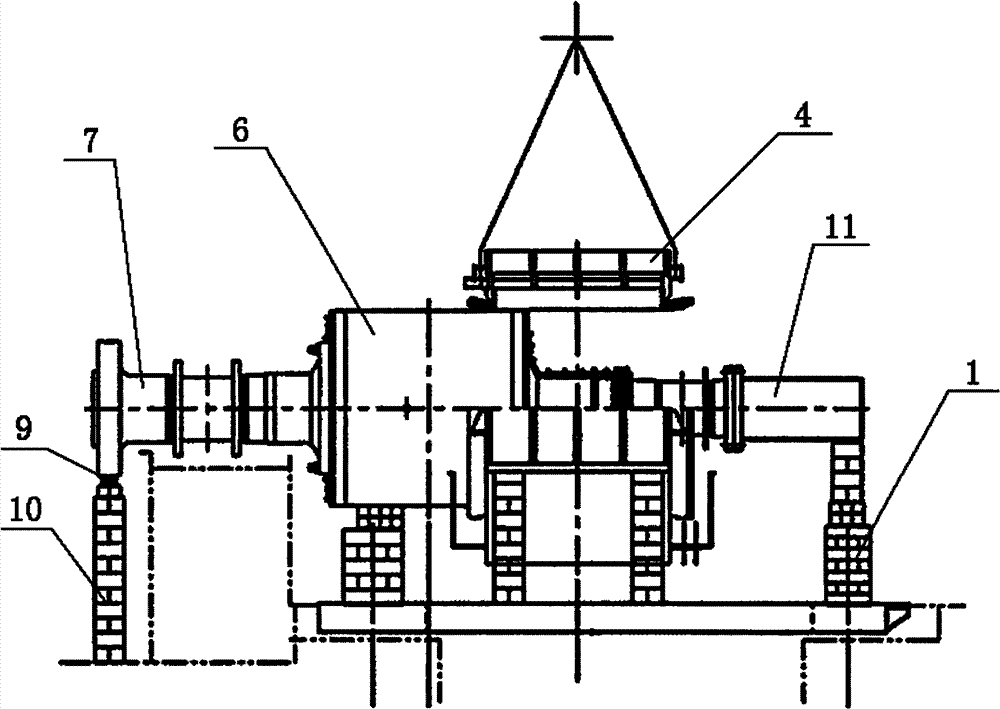

[0026] A method for hoisting the main drive motor of a roughing mill. The method adopts the form of hoisting first and then assembling to install the rotor 6 and the stator 4 of the main drive motor of the roughing mill. The specific steps of the present invention are as follows, as Figure 1 to Figure 6 Shown:

[0027] 1) Build the stator base 3 and the rotor base 1 at the installation position of the motor, the stator base 3 and the rotor base 1 are made of square bricks, the rotor base 1 is set on both sides of the stator base 3, respectively The pad 2 is installed on the seat 3 and the rotor base 1, the pad 2 is made of I-shaped steel, and the pad 2 is fixed on the base by bolts;

[0028] 2) Before lifting the stator 4, clean the inside of the stator 4 and the surface of the rotor 6, and wrap up the shaft diameter part where the bearing is placed to prevent the stator 4 from being scratched and damaged during the installation process, and prevent pollutants from entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com