Horizontal axial-suction sectional multistage high-pressure centrifugal pump

A high-pressure centrifugal pump, segmental technology, applied in the field of segmental multi-stage high-pressure centrifugal pumps, can solve the problems of pump length and poor reliability of pump operation, and achieve the effects of improved reliability, simple installation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

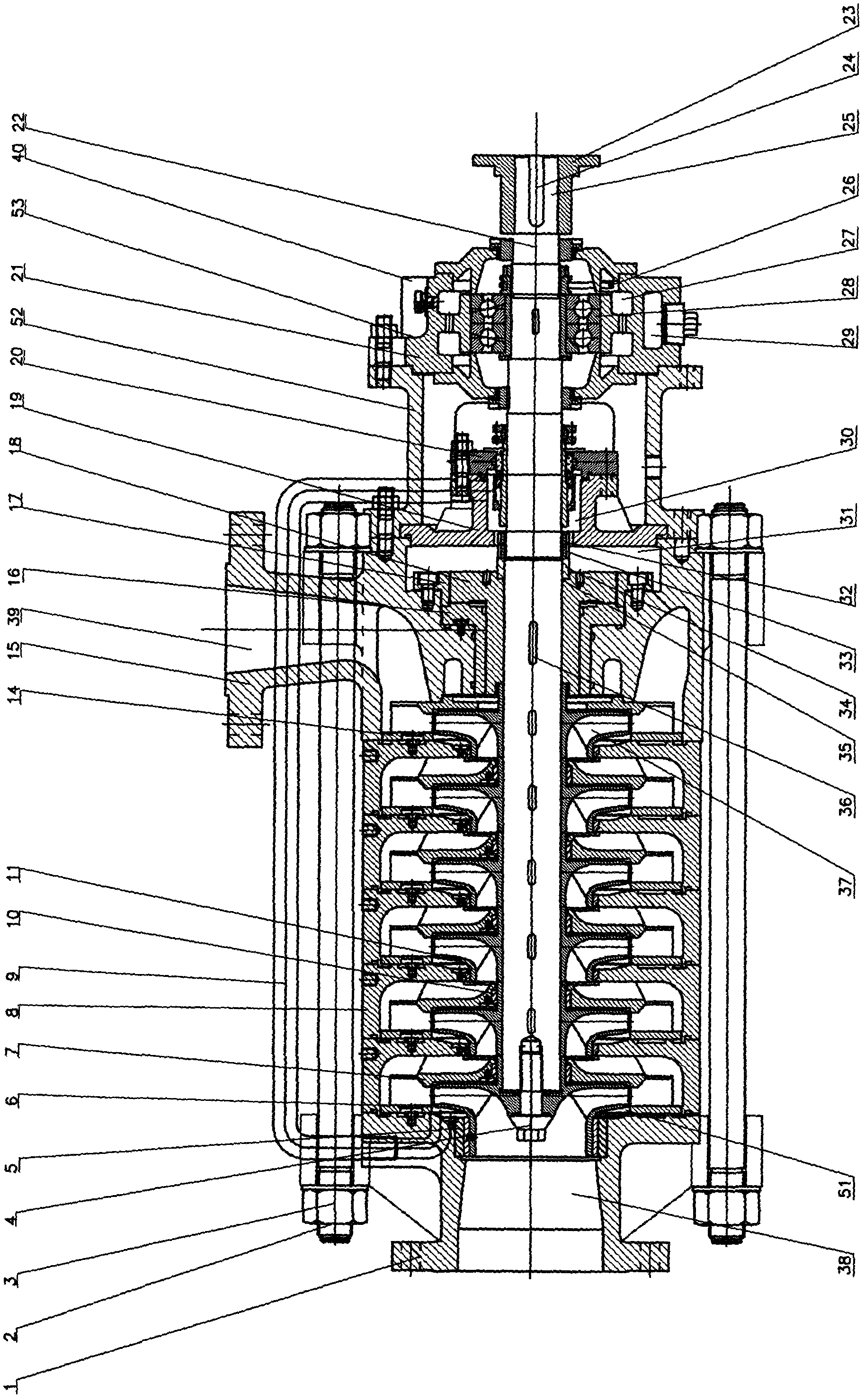

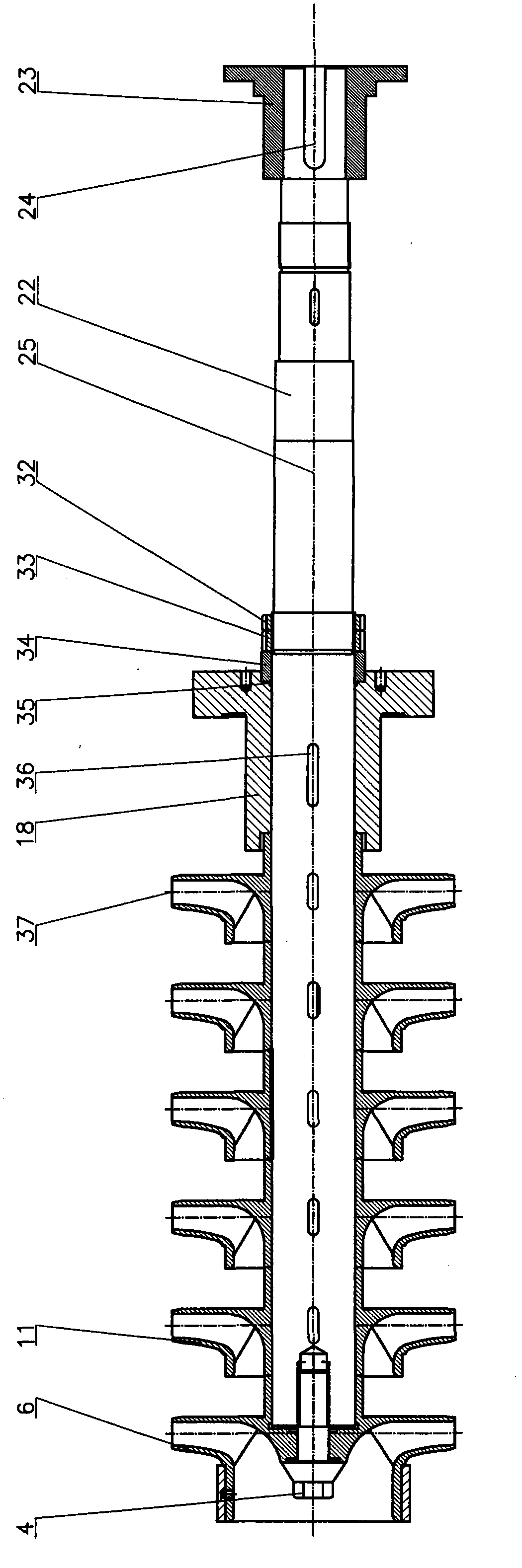

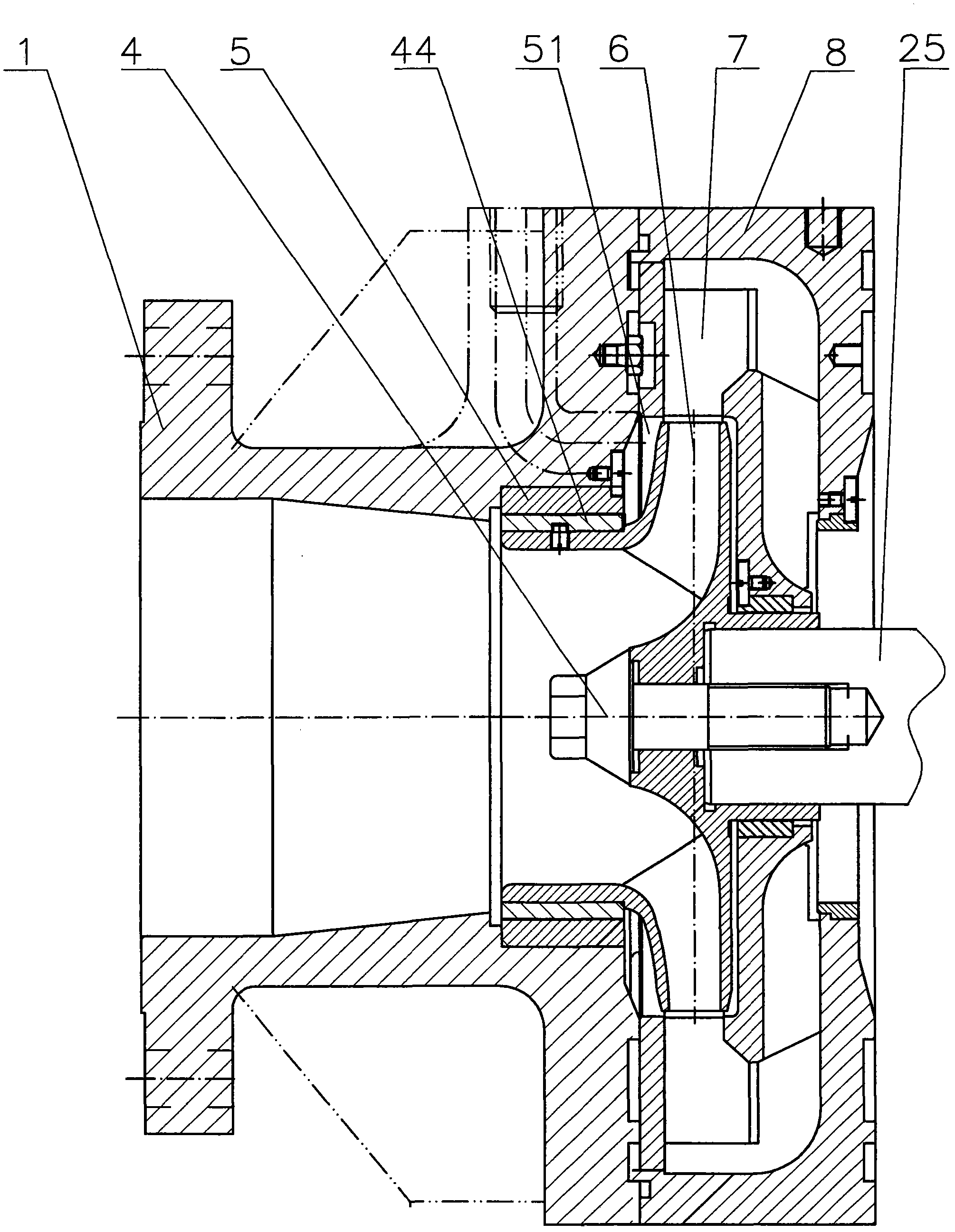

[0015] With reference to the accompanying drawings, it can be seen that the horizontal axial suction segmental multistage high-pressure centrifugal pump of the present invention includes a pump housing assembly, a rotor assembly 22, a bearing assembly 21, and a sealing cover 19, wherein the pump housing assembly is composed of successively connected suction section shells. Body 1, middle section housing 8, spit out section housing 15 to form (as figure 1 As shown, the two ends of the tension bolt 2 are respectively fixed on the suction section shell 1 and the discharge section 15 shell with tension nuts 3, and the middle section shell 8 is clamped and fixed), and the rotor assembly is multi-stage impellers arranged in the same direction The segmented structure includes first-stage impeller 6, secondary impeller 11 (several), guide vanes 7 (several, including first-stage guide vanes 42, last-stage guide vanes 14), rotating shaft 25 (such as figure 2 shown), the first-stage imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com