Electrical machine comprising a rotor, and method for operating said electrical machine

A rotor and running technology, applied in the field of motors with rotors, can solve problems such as motor interference and noise, and achieve the effect of improving the scheme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

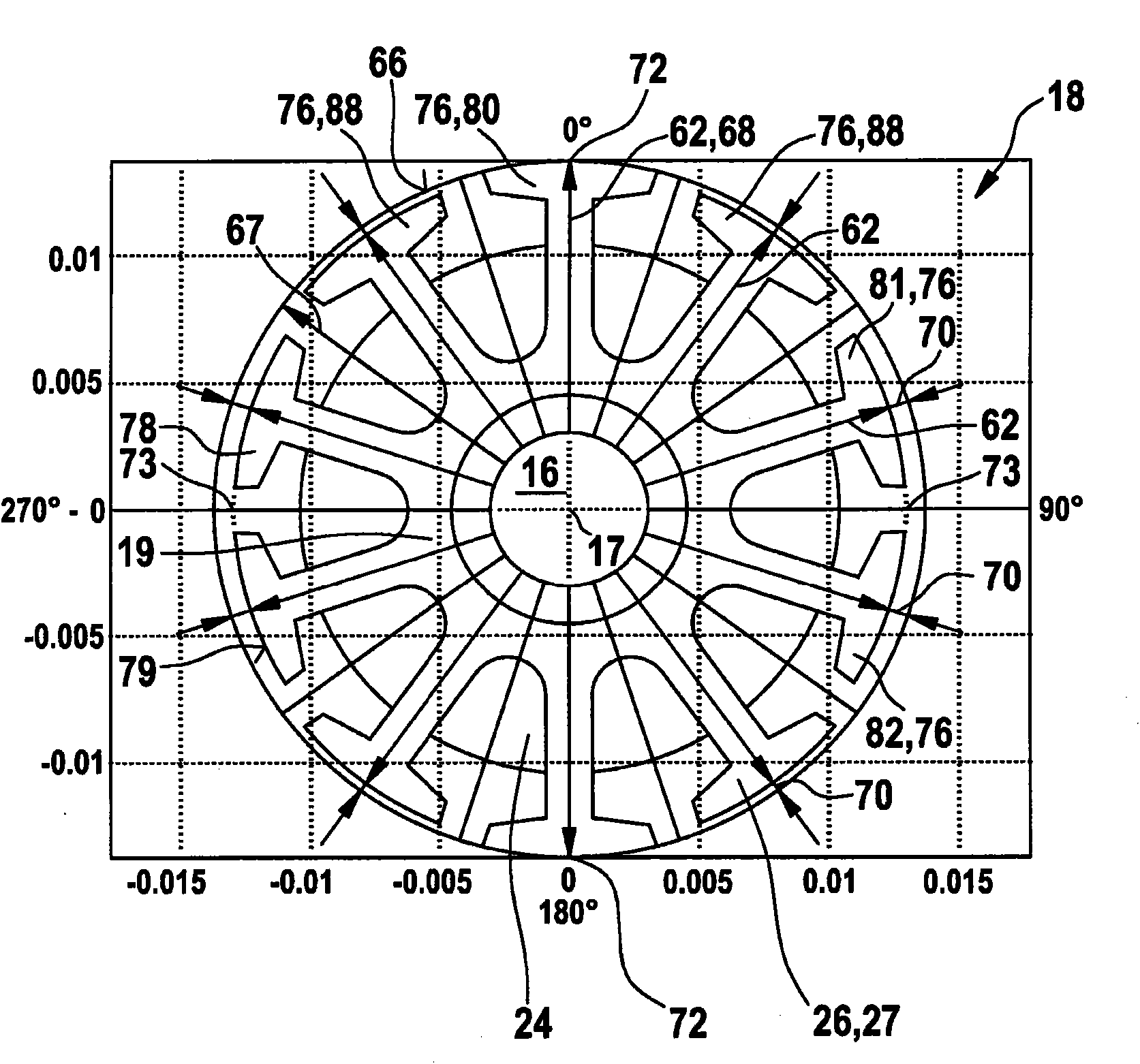

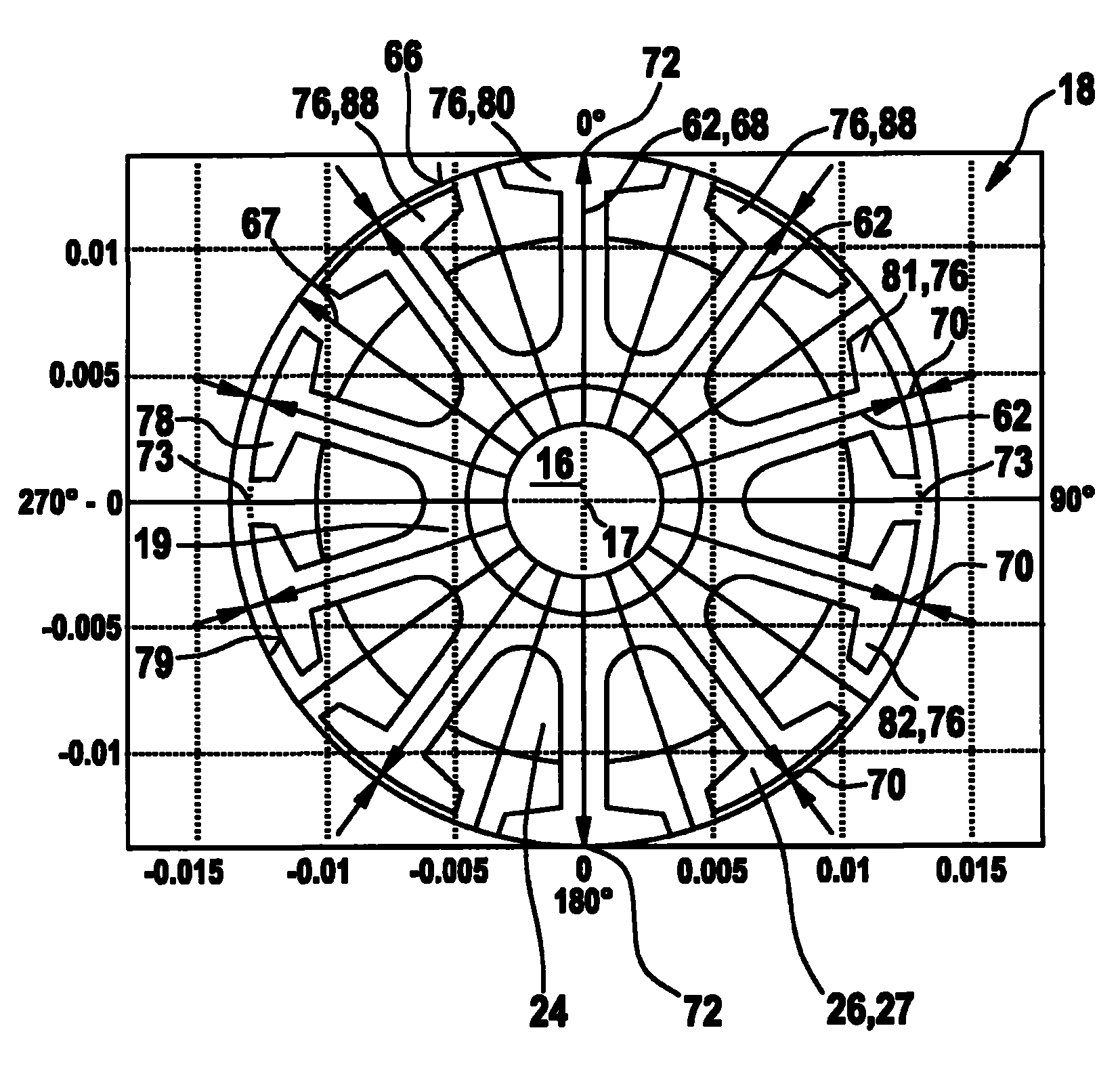

[0020] exist figure 1 A rotor 18 of an electric machine 12 , which is designed, for example, as a DC motor 14 , is shown in . The rotor 18 has a rotor shaft 16 , on which an armature 19 is arranged in a rotationally fixed manner, which is designed, for example, as a lamination pack 26 consisting of individual laminations 27 joined axially together. The rotor 18 has a radius 62 which extends from the axis 17 of the rotor shaft 16 to the outer circumferential surface 64 of the rotor 18 . exist figure 1 A circle 66 is depicted in an auxiliary manner, which has a radius 67 which corresponds to the maximum radius 68 of the rotor 18 . The radius 62 is not constant over the circumference of the rotor 18 , but varies over the circumference, so that a varying length difference 70 of the radius 62 is obtained. The variation of the length difference 70 is preferably sinusoidal or cosine-shaped over the circumference of the rotor 18 . In the example shown, a maximum value 72 of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com