Boiling drying device

A technology of boiling drying and tank body, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc. It can solve the problems that the drying technology cannot meet the technical requirements well, the product has too much moisture, and the product loses its application characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

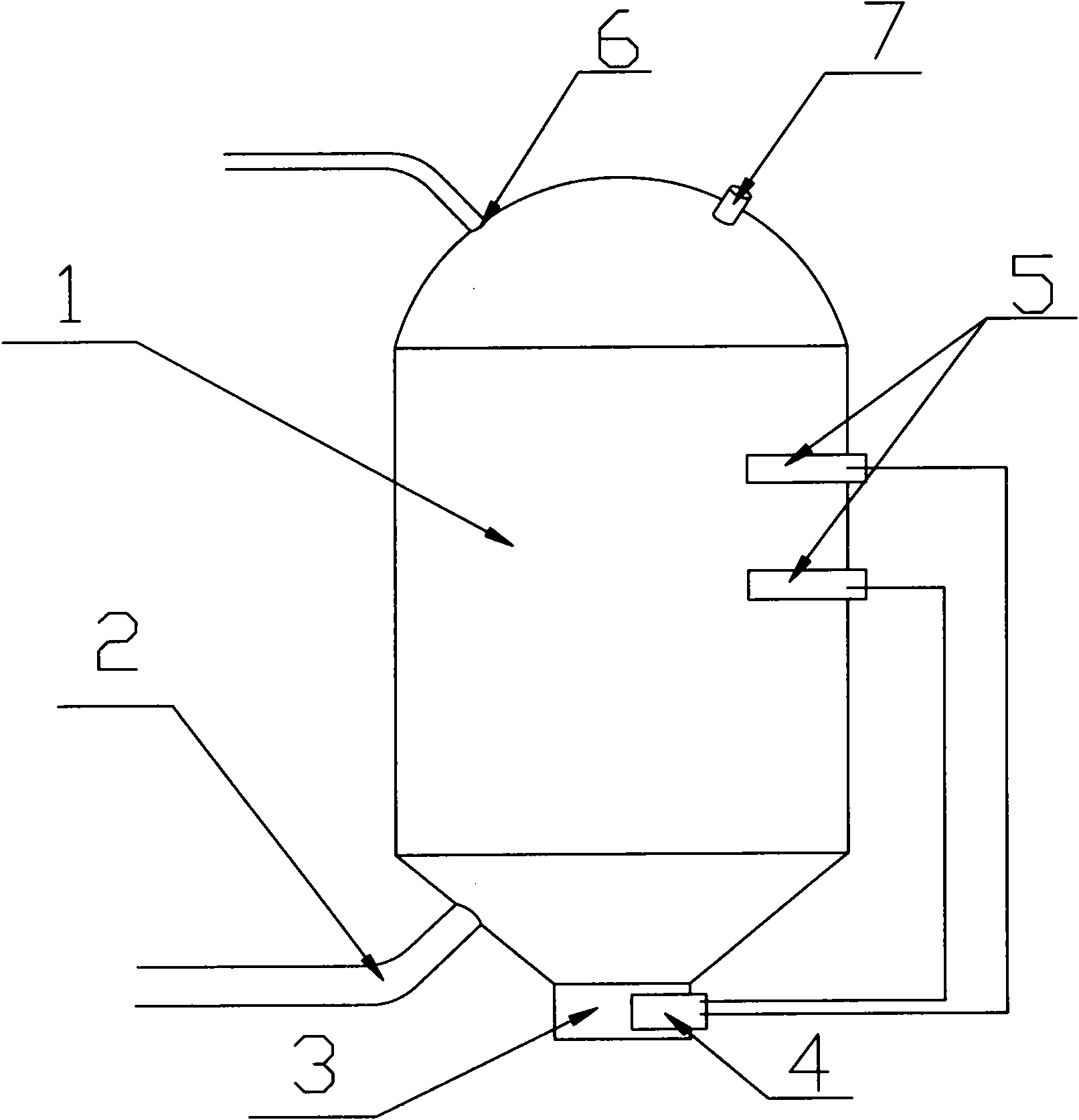

[0011] like figure 1 A kind of boiling drying device shown, comprises tank body 1, and the top of tank body 1 has feed inlet 6, and the bottom of tank body 1 is provided with discharge port 3, and the side wall below of described tank body 1 has hole, connects Pipeline 2; said pipeline 2 has at least one; said pipeline 2 is symmetrical about the center of tank body 1; said discharge port 3 is provided with a flow control valve 4, and said side wall is provided with a control valve The induction control switch 5 of the flow control valve 4; the induction control switch 5 is provided with two upper and lower ones.

[0012] Inject the product into the tank 1 through the feed port 6, pass air into the pipeline 2, use the air to blow the plastic particle product into a boiling state like boiling water, and add more and more raw materials. When the height of the product reaches the lower part When the induction control switch 5 is activated, the lower induction control switch 5 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com