Epiphysis retardant built-in 8-shaped steel plate and application thereof

A technology of steel plate and epiphysis, applied in the field of built-in 8-figure plate in epiphyseal block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

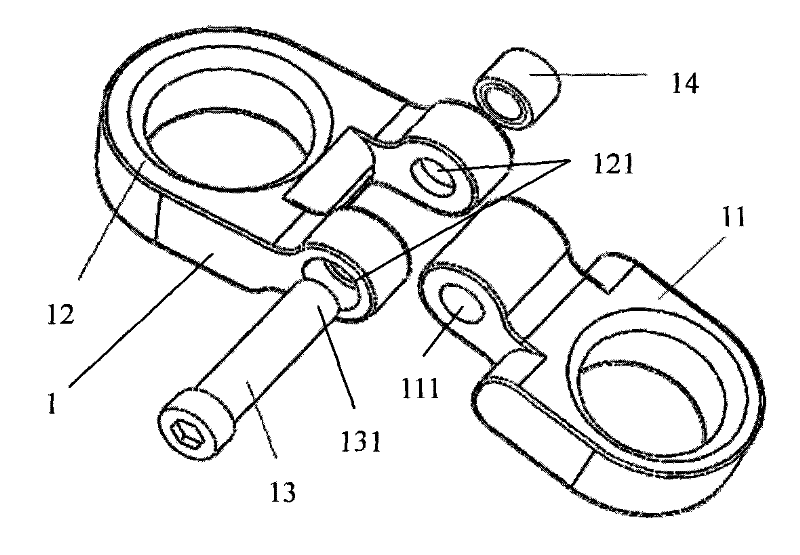

[0058] 8-shaped steel plate fixed by screws and nuts

[0059] Please refer to the attached figure 1 , with figure 1It is a structural schematic diagram of a 8-shaped steel plate fixed by screws and nuts. The 8-shaped steel plate 1 includes a first one-side orifice 11, a second one-side orifice 12, a screw 13 and a nut 14, and the one-side orifice 1 and the one-side orifice 2 are respectively designed with first The hinge hole 111 and the second hinge hole 121 . The head of the screw rod 13 has threads 131, and the nut 14 is circular. The two one-sided orifice plates are connected through the first hinge hole 111 and the second hinge hole 121 by the screw rod 13 and the nut 14 . When assembling, make the first hinged hole 111 and the second hinged hole 121 coaxial, insert the screw rod 13, and screw the nut 14 on the screw thread 131, then the 8-shaped steel plate 1 is assembled.

Embodiment 2

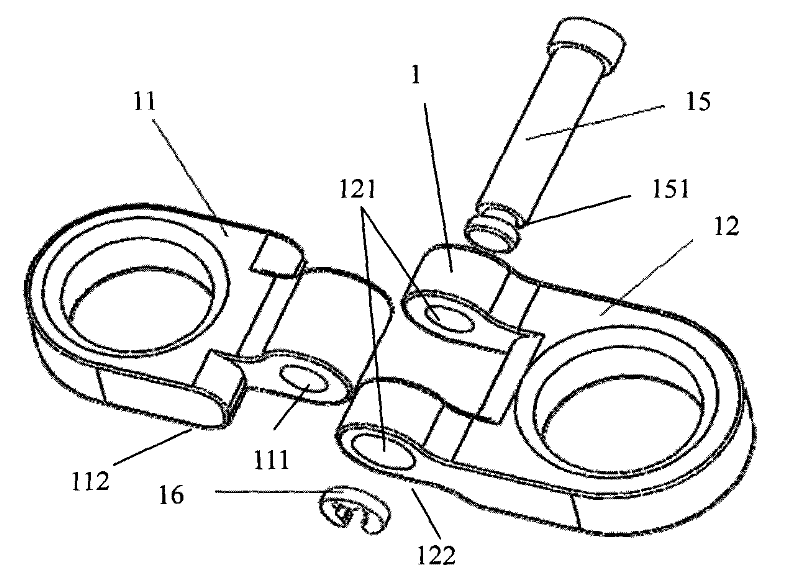

[0061] 8-shaped steel plate fixed by screw and circlip

[0062] Please refer to attached figure 2 , with figure 2 It is a schematic diagram of the structure of the 8-shaped steel plate fixed by the slotted screw and the circlip. The 8-shaped steel plate 1 includes a first one-side orifice plate 11, a second one-side orifice plate 12, a groove screw 15 and a retaining spring 16, and the first one-side orifice plate 11 and the second one-side orifice plate 12, a first hinge hole 111 and a second hinge hole 121 are respectively designed. The head of the slot screw 15 has a slot 151 . The two one-sided orifice plates are connected by the slotted screw 15 and the snap spring 16 through the first hinge hole 111 and the second hinge hole 121 . When assembling, make the first hinged hole 111 and the second hinged hole 121 coaxial, insert the screw rod 15 into the draw-in groove, install the jump spring 16 at the draw-in groove 151, and then the 8-shaped steel plate 1 is assemble...

Embodiment 3

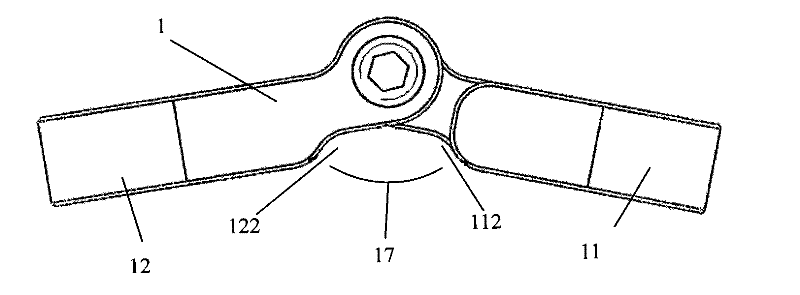

[0065] Combination of 8-shaped steel plates of different sizes

[0066] The first one-side orifice 11 and the second one-side orifice 12 of the 8-shaped steel plate 1 include three different sizes and specifications, that is, the distances from the center hole to the pivot hole are 6mm, 8mm and 10mm respectively, and these orifices can be assembled in total. It is made into 8-shaped steel plates of 6 different specifications. According to the actual size of both sides of the patient's epiphysis, the doctor chooses different matching combinations among the 6 matching methods.

[0067] (1) Symmetrical 8-shaped steel plate 6mm-6mm combination

[0068] Please refer to attached Figure 4 , with Figure 4 It is a structural schematic diagram of a combination of symmetrical 8-shaped steel plates of 6mm-6mm. When installing, select the first one-side orifice plate 11 with a size of 6mm and the second one-side orifice plate 12 with a size of 6mm, and assemble them according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com