Carrier rod type gate for injection mold

An injection mold and ejector type technology, which is applied in the field of layout mechanism, can solve the problems of long injection cycle, unstable working process, and increased mold use cost, and achieve the effects of shortened injection cycle, convenient processing and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

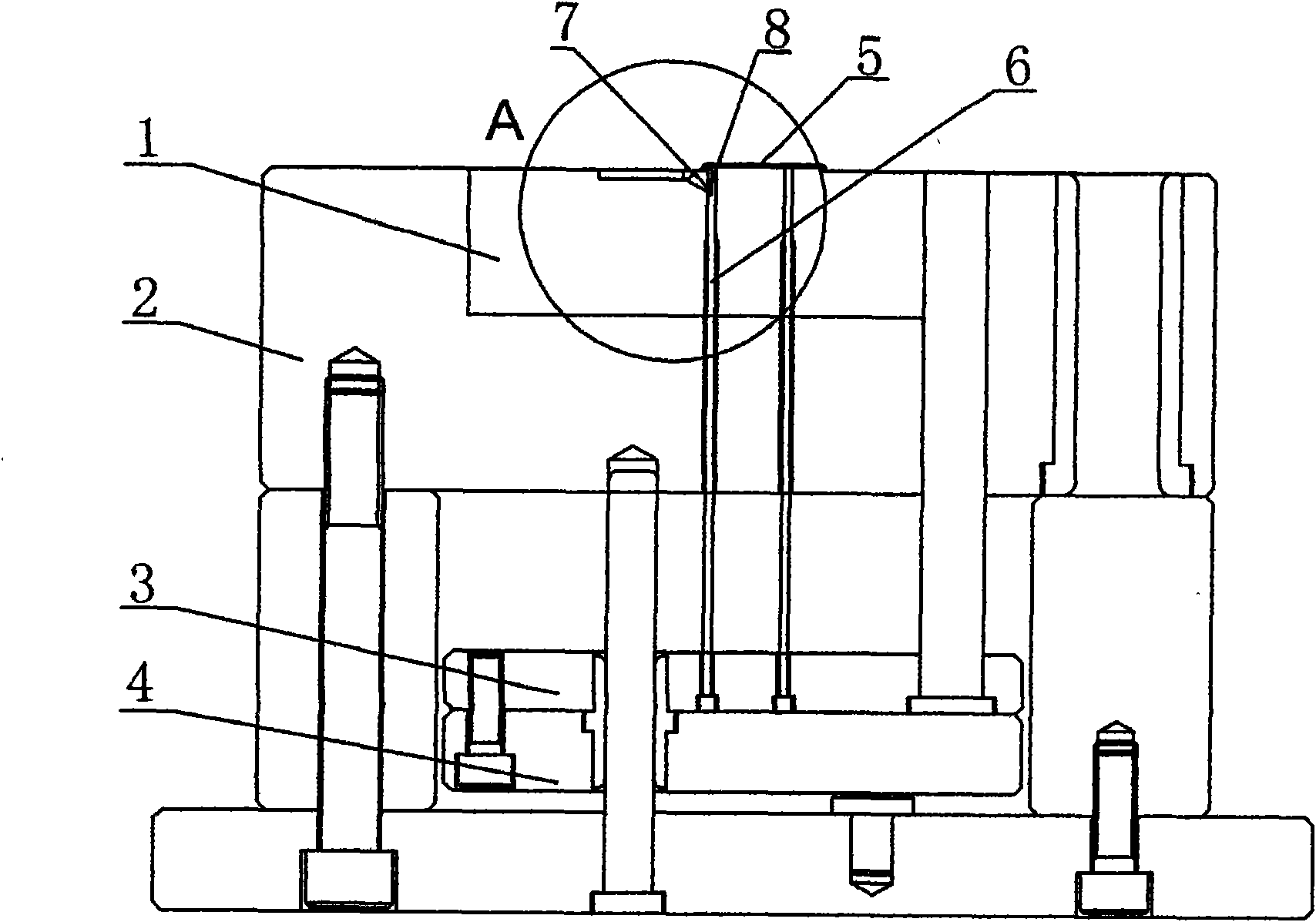

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

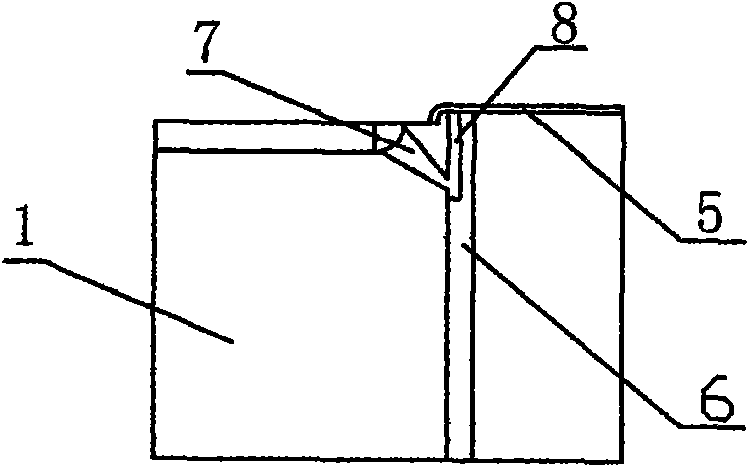

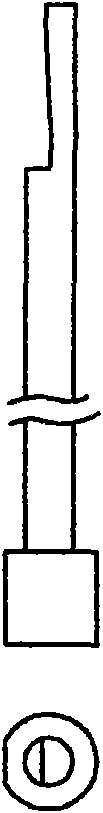

[0012] Such as Figure 1~4 As shown, the ejector gate of the injection mold includes a movable model cavity 1, a movable template 2, a push rod fixing plate 3, a push plate 4, a ejector rod 6, and a runner 7. The movable model cavity 1 is fixed on the movable template 2 by screws. On the surface of the movable model chamber 1, there is a runner 7, and the ejector rod 6 is fixed on the push rod fixing plate 3 through the push plate 4. The gap 8 communicates directly opposite.

[0013] The cavity formed by the semicircular notch 8 is the gate, and the size of the gate can be changed by modifying the size and height of the notch for different product sizes and thicknesses. In order to ensure the strength of the ejector pin 6, it is recommended that its diameter should not be less than 3mm. In order to ensure that the products with special shapes can be taken off smoothl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com