Direct pushing core drawing device

A core-pulling device and straight jacking technology, which is applied in the field of mold core-pulling, can solve problems such as the inability to use inclined jacks and the inability to force ejection of undercuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

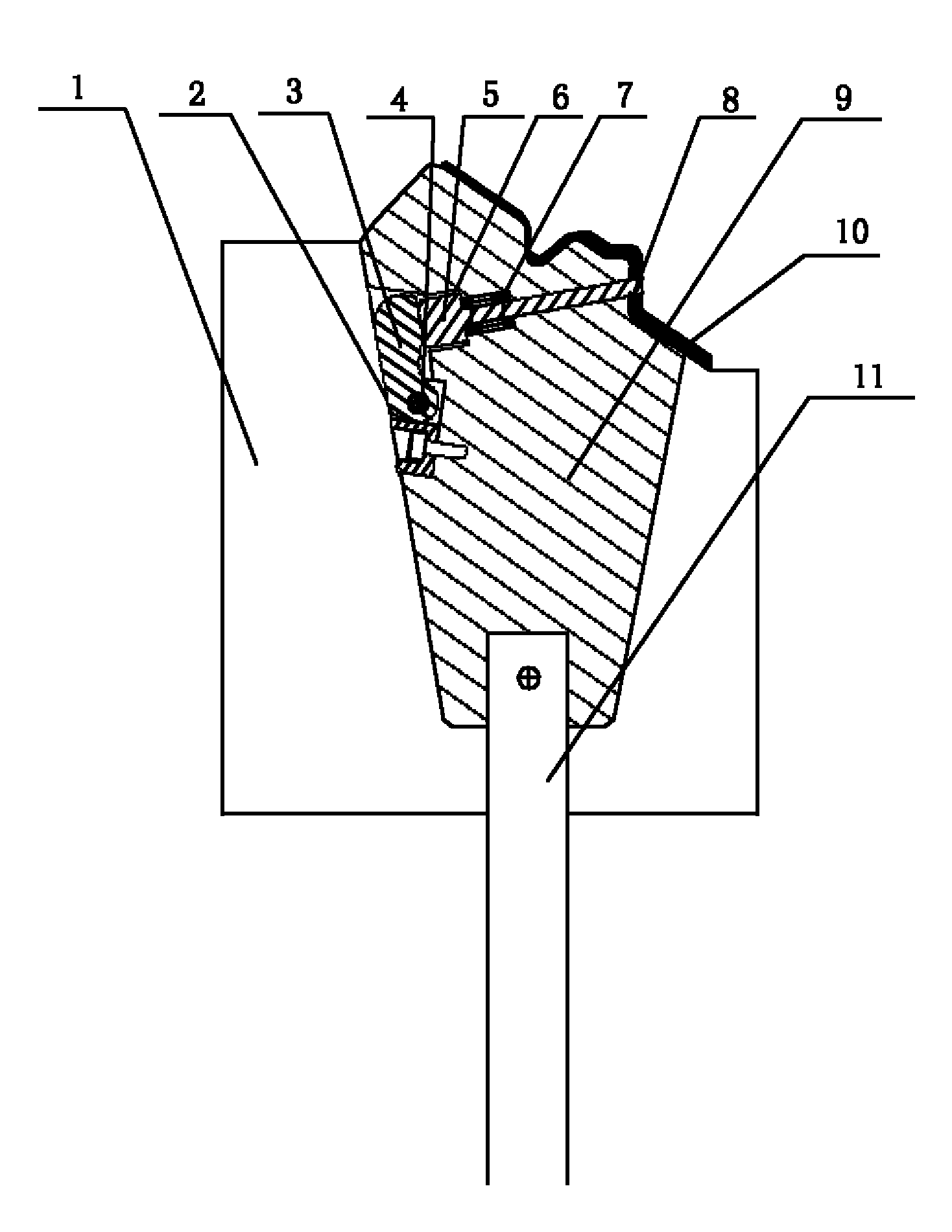

[0007] See figure 1 , a straight top core-pulling device of the present invention, including a slanted top 9, a slanted top rod 11 and a lower mold cavity 1, a T-shaped slanted thimble pin 5 is movably installed on the slanted top 8 through a slanted top sinker 6 and a spring 7, and a stopper 3 is movably connected with the slanted top 9 through the column pin 4, the stopper 3 is in contact with one end of the T-shaped slanted thimble 5, the stopper 3 compresses the spring 7 through the T-shaped slanted thimble 5, and the slanted top 9 is placed in the lower mold cavity 1, showing V-shaped contact (2 in the figure is the contact surface between the inclined top 9 and the lower mold cavity 1). The inclined thimble is pulled out to make the undercut 8 in the product 10 release. Since the stopper is placed in the lower mold cavity by relying on the spring to compress the T-shaped slanted thimble, when the mold is ejected, the slanted ejector leaves the contact surface, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com