Super-thick copper circuit board solder resisting processing method

A processing method and circuit board technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve problems such as electric corrosion, increase brushing process, and high cost of filling resin, so as to reduce production cost and shorten Production process, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

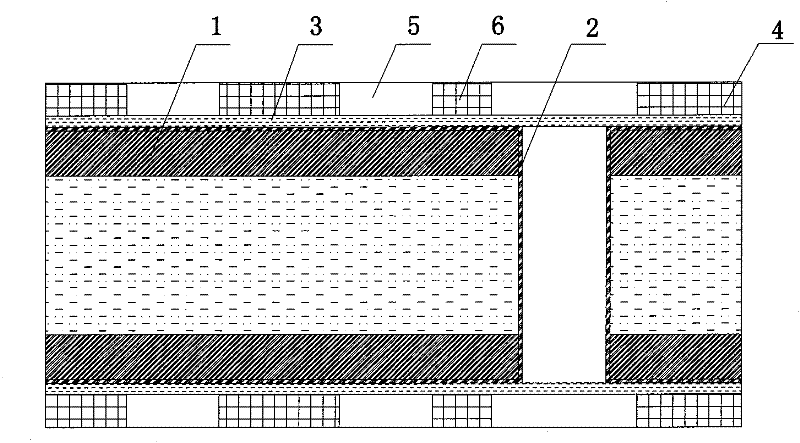

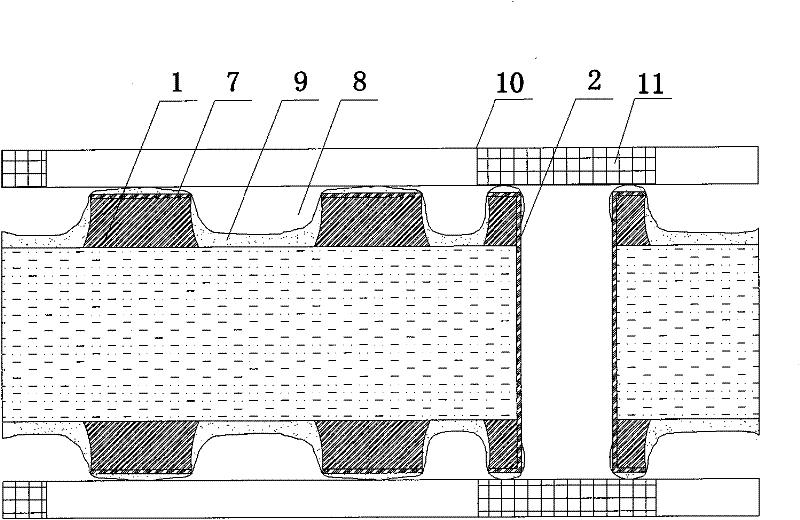

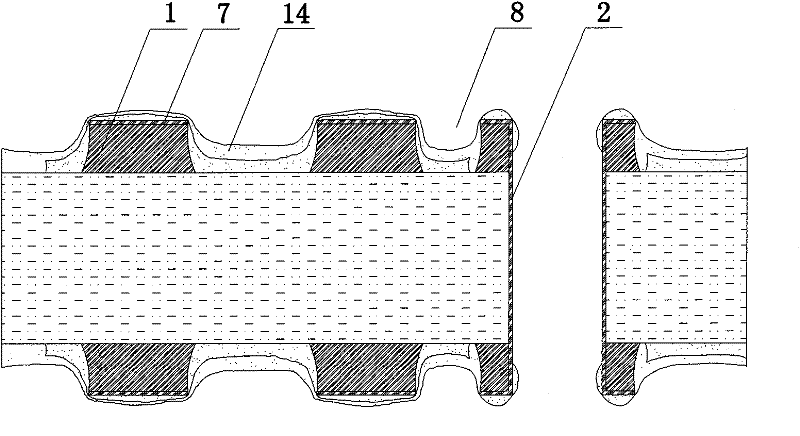

[0043] The present invention mainly adopts the current popular electrostatic spraying process to replace the traditional flat solder resist printing processing process. During electrostatic spraying, it adopts four times of spraying and two times of pre-baking-exposure-development-curing for processing. There is no pre-baking-exposure-development-curing between the first and the last two electrostatic sprayings, but only cold air blowing, which can not only ensure that the ink does not sag after the first and third spraying, but also reduce the process. Steps to fully meet the performance requirements of the product at the lowest cost.

[0044] The processing method of the ultra-thick copper circuit board comprises the following steps:

[0045] a. Press the multi-layer board with the outer copper foil thickness of 11oz or directly cut the double-sided board with the outer copper foil thickness of 11oz; (the following takes the double-sided board as an example),

[0046] b. Dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com