Air spring for vehicle and hanger mounting method thereof

A technology of an air spring and an installation method, which is applied in directions such as a gas shock absorber, a device for lateral relative movement between an underframe and a bogie, etc., can solve problems such as wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

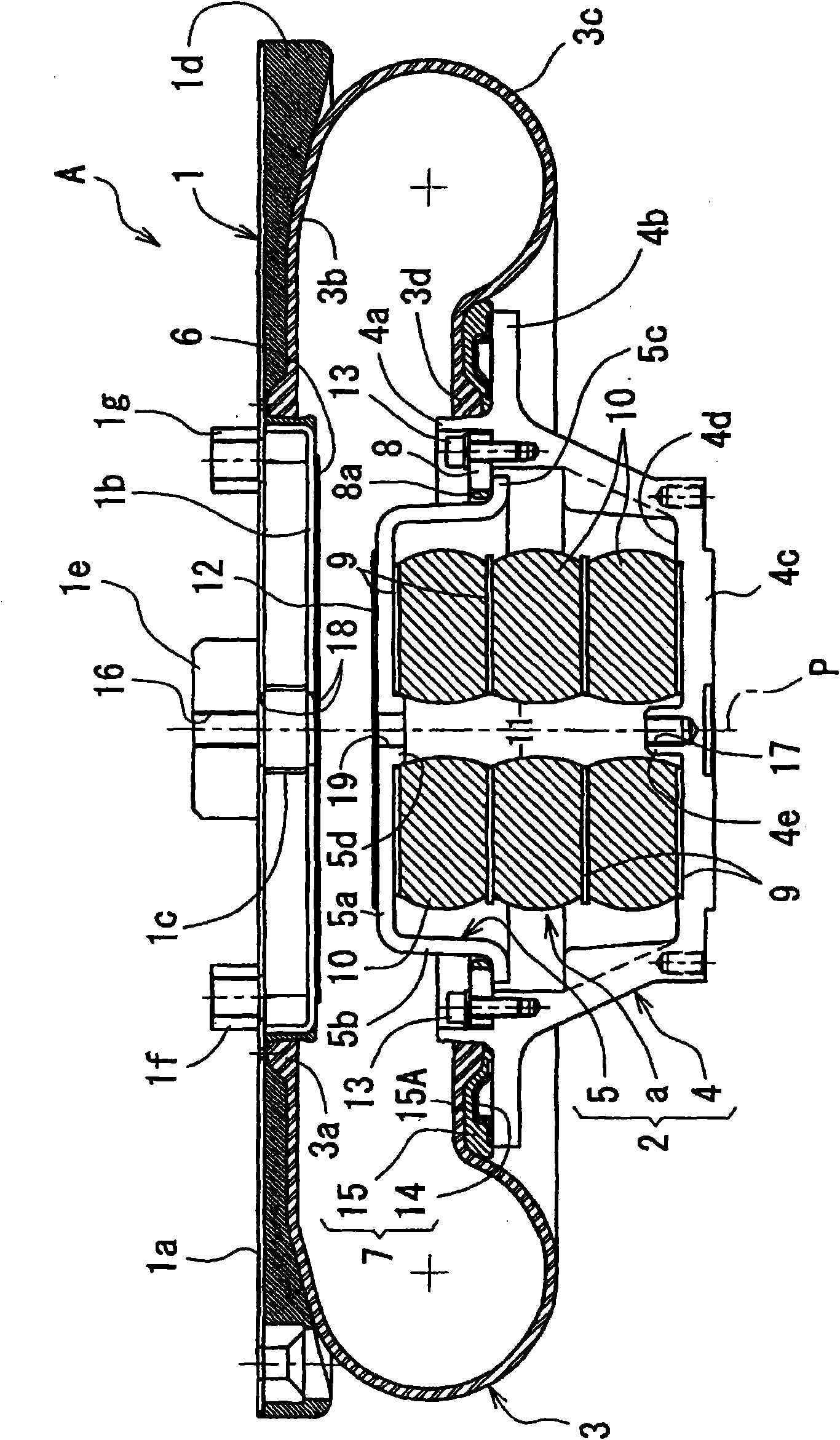

[0052] figure 1 , 2 An air spring (hereinafter, simply referred to as "air spring") A for a railway vehicle is shown. This air spring A is configured to include: an upper support part 1 on the vehicle body side; a lower support part 2 on the chassis side disposed below the upper support part 1; and a diaphragm 3 made of rubber (an example of an elastic material). It is provided so as to straddle the above-mentioned upper support part 1 and lower support part 2 . The lower support portion 2 is configured as an elastic stopper having a lower bracket 4 supported on the chassis, an elastic portion a of laminated rubber construction, and a pressing cover (also referred to as a bead seat) 5 .

[0053] The upper support part 1 is configured to have: a support seat 1a made of steel plate, which is circular when viewed in the up-down direction; Disc-shaped; gasket 1c with holes, which straddles the above two 1a, 1b and is fixed, and has a cylindrical shape with an upper and lower a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com