Baffle plate mechanism of observing window

A technology of baffle mechanism and observation window, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as affecting observation effect, human safety or health threat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

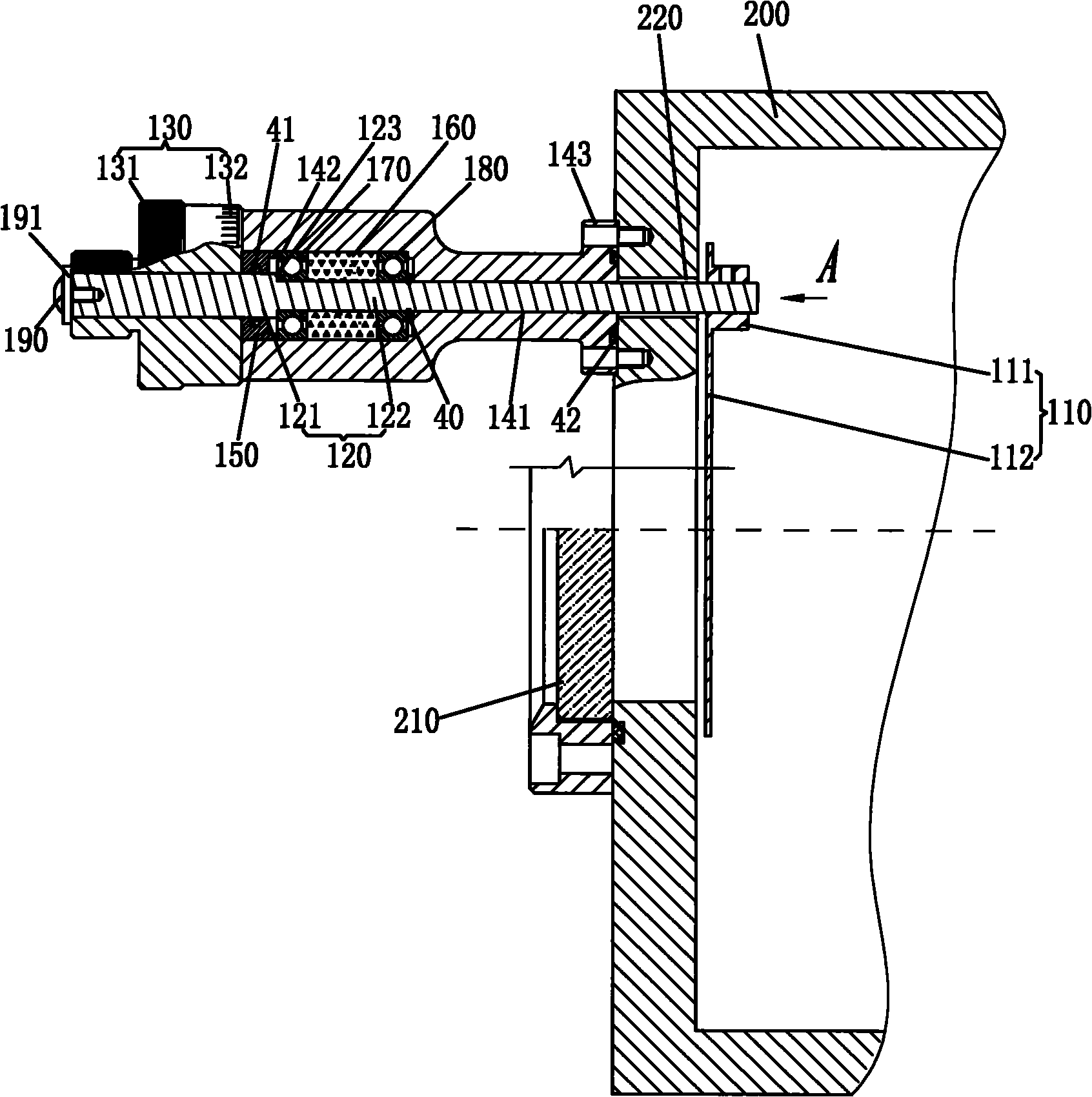

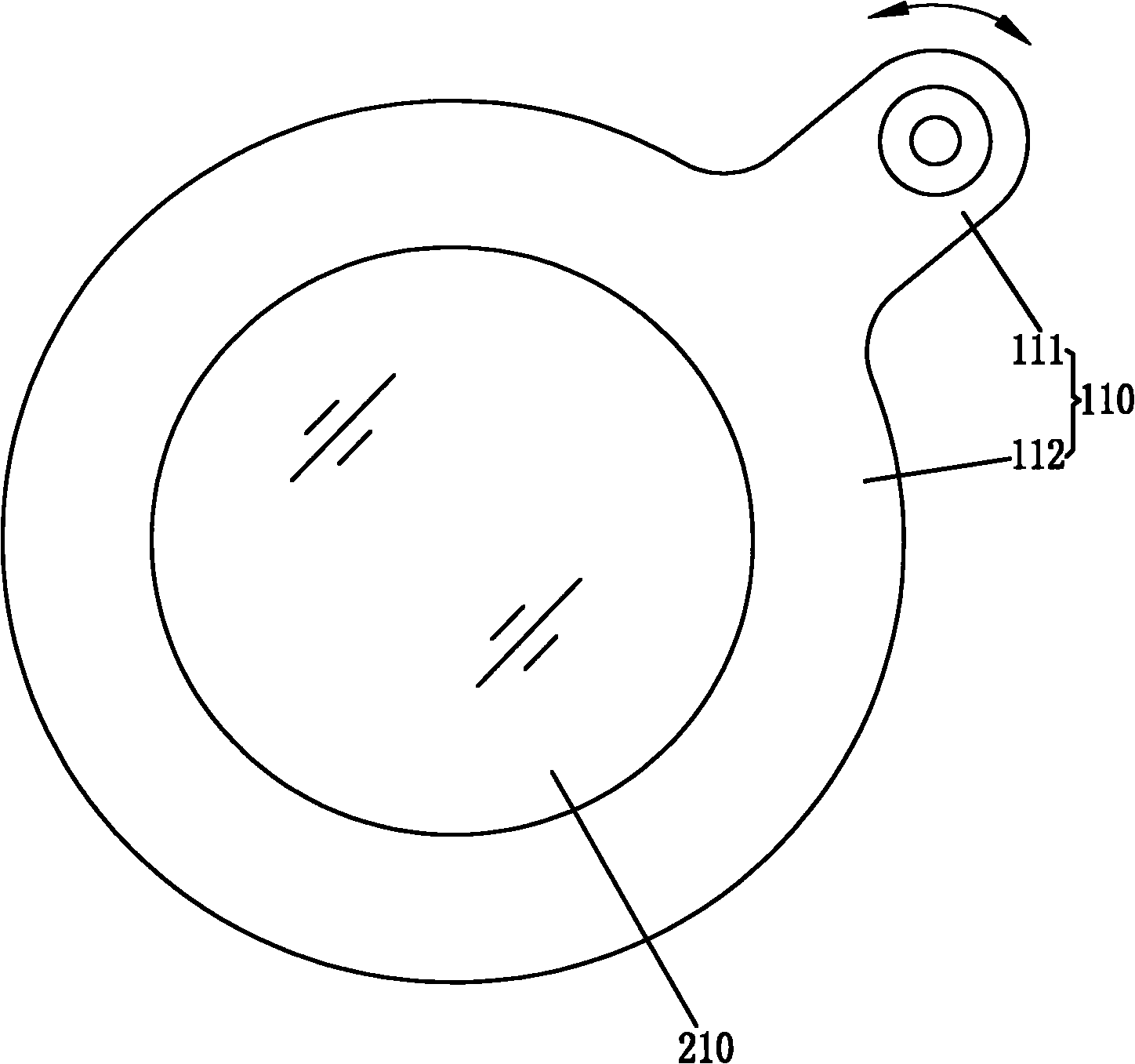

[0025] figure 1 It is a schematic cross-sectional view of the first embodiment of the observation window baffle mechanism of the present invention. combine Figure 1 to Figure 3 , the observation window baffle mechanism 100 of the present invention is connected to the vacuum cavity 200 and is used to block the observation window 210 on the vacuum cavity 200 .

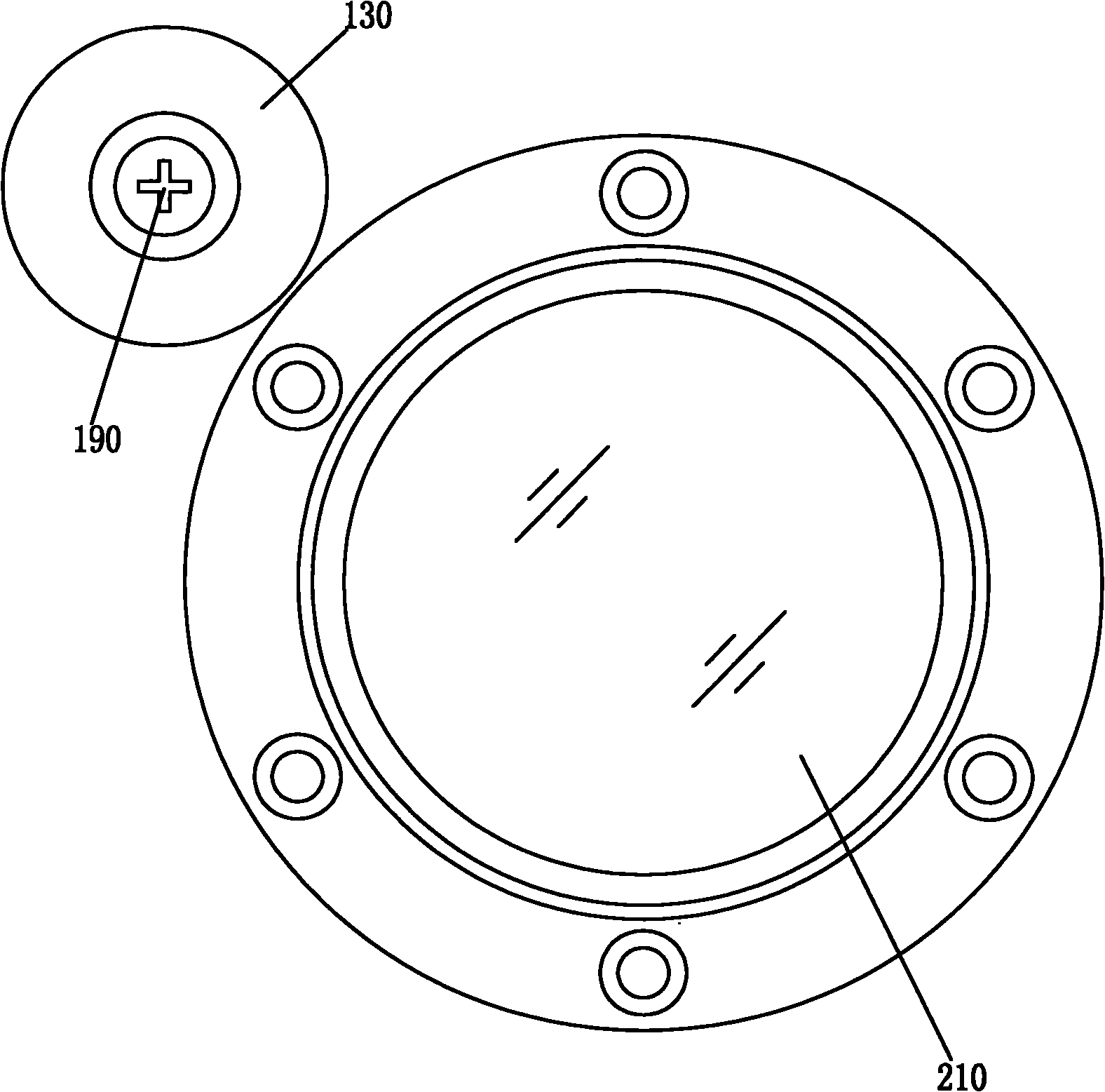

[0026] refer to Figure 4 , the observation window baffle mechanism 100 includes a baffle 110 , a rotating shaft 120 , a rotating handle 130 , a fixing base 140 , a collar 150 , a magnetic fluid 160 , a first bearing 170 and a second bearing 180 .

[0027] refer to Figure 5 The rotating shaft 120 includes a first rotating shaft 121 and a second rotating shaft 122 . In this embodiment, the diameter of the first rotating shaft 121 is greater than the diameter of the second rotating shaft 122 . A step 123 is formed between the first shaft 121 and the second shaft 122 . A flat key 124 is disposed on the first rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com