Butterfly valve center hole processing fixture

A center hole and butterfly valve technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not being suitable for large-scale production, low production efficiency, complicated procedures, etc., to simplify the line drawing process of the fitter, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

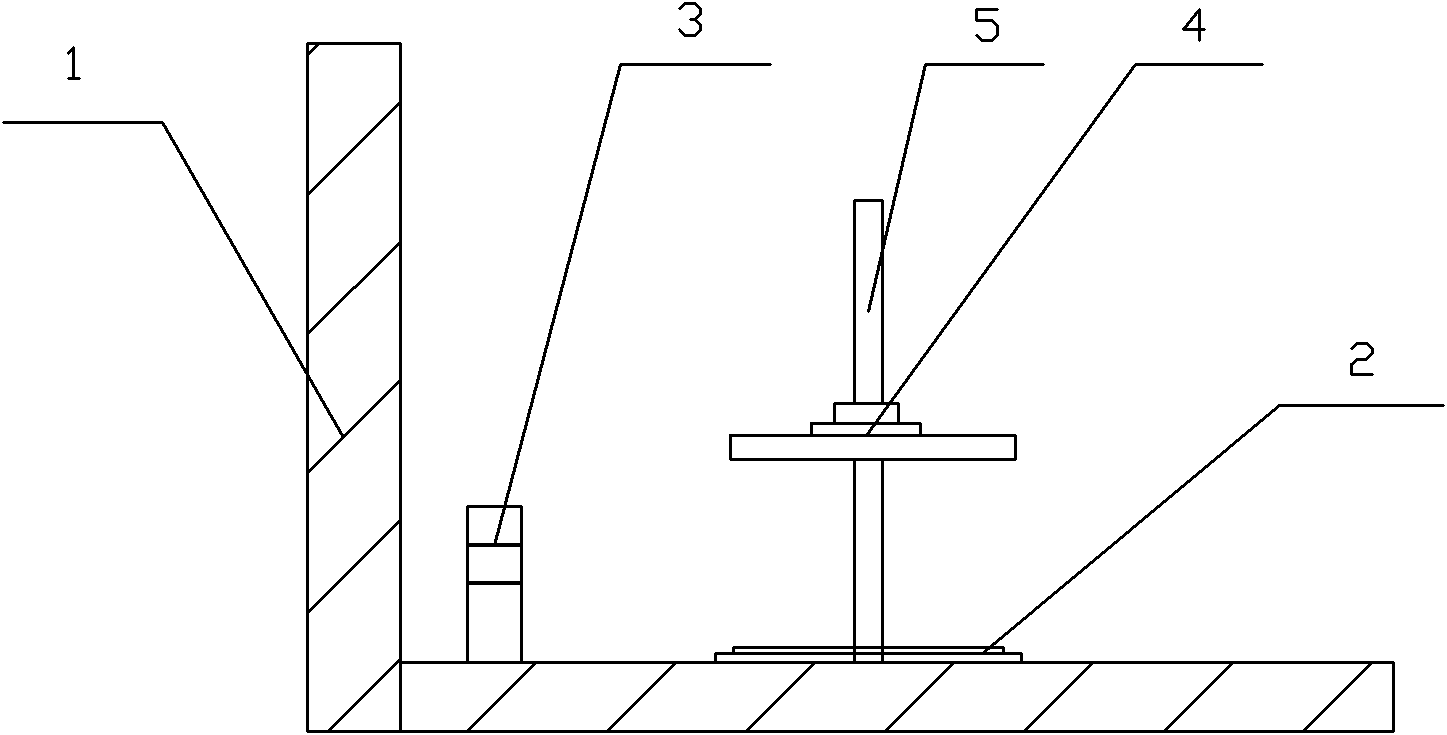

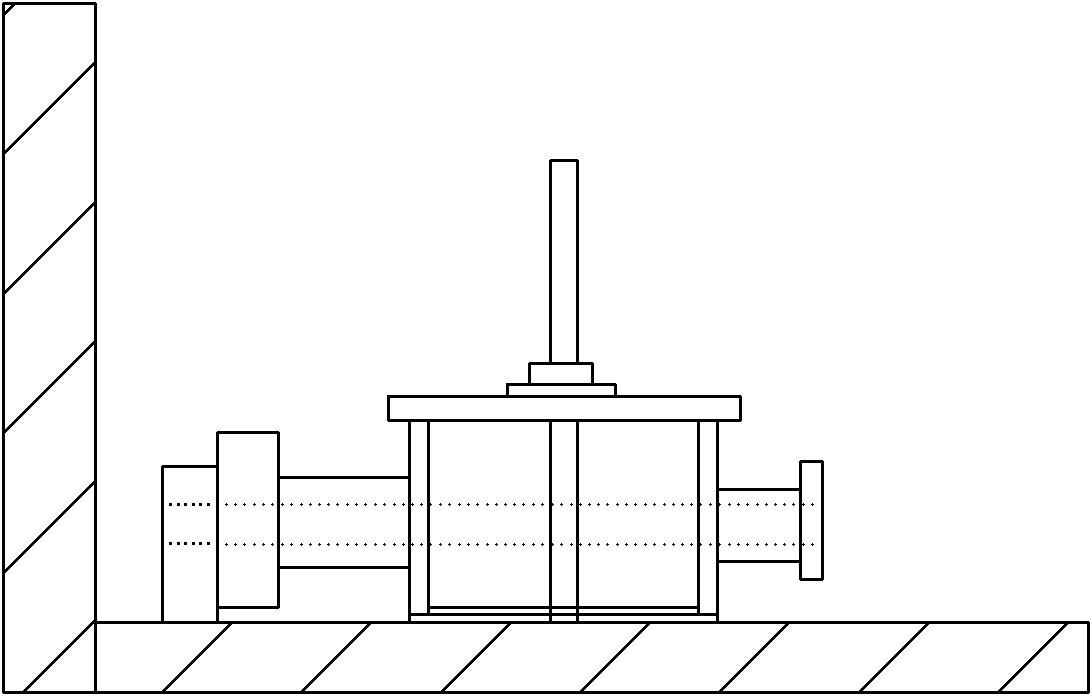

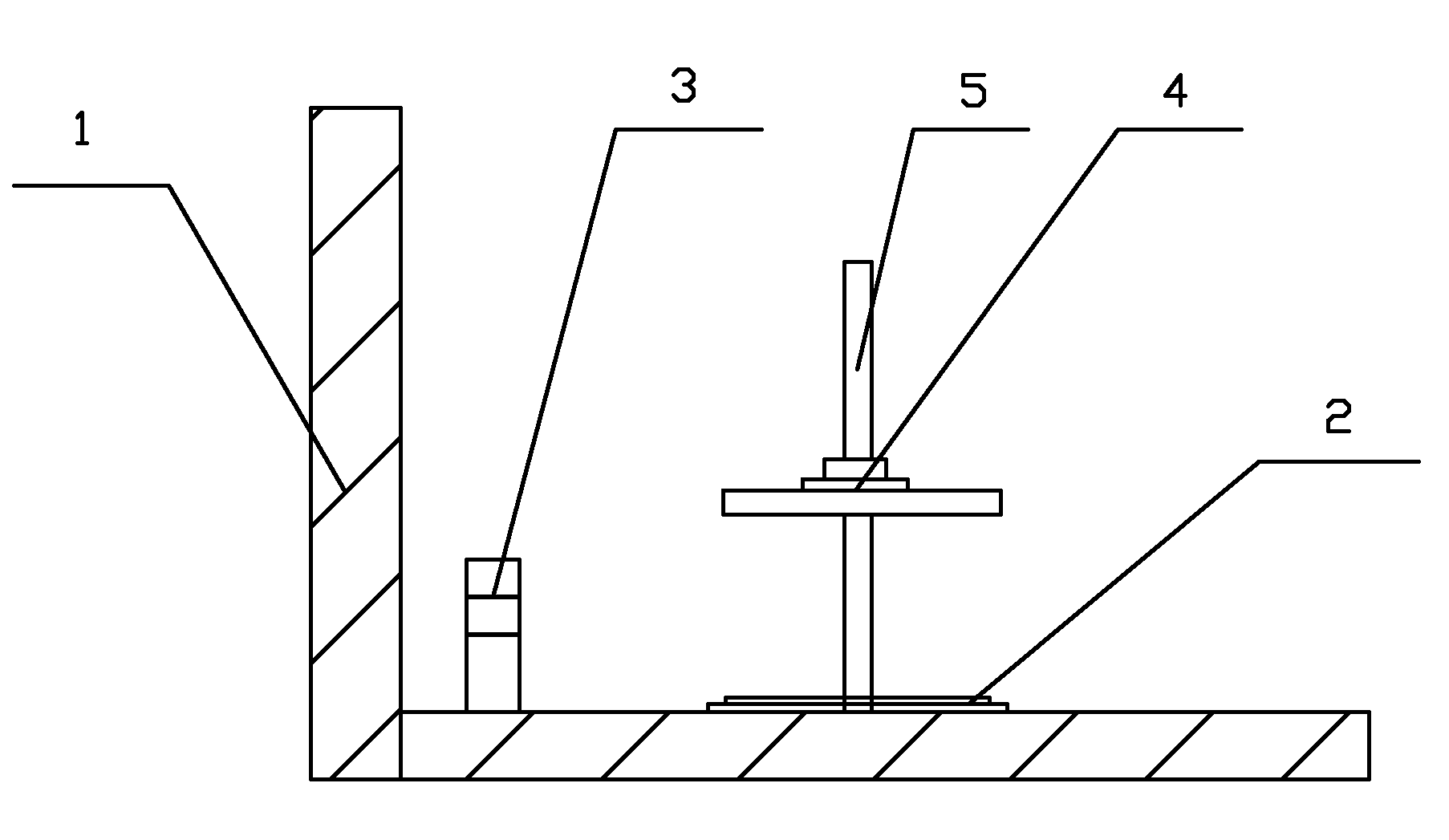

[0008] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a fixture for processing the center hole of a butterfly valve is mainly composed of a bent plate 1 connected to the spindle of the lathe, a positioning plate 2 for the inner diameter of the butterfly valve, a drilling mold 3 and a pressure plate 4, and the positioning plate 2 is fixed on the right-angled plane of the bent plate Above, the positioning plate 2 is vertically provided with fixing bolts 5 along the center line, the pressure plate 4 is sleeved on the bolts 5, and the positioning plate 2 is fixed with a drilling template 3 along the central axis of the lathe.

[0009] When in use, the valve port of the butterfly valve is placed on the inner diameter positioning plate 2 of the butterfly valve, the pressure plate is set on the bolt and the nut is tightened, and the center hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com