Diode laser structure to generate diode laser radiation with optimized fiber coupling radiation parameter product

A diode laser, beam parameter product technology, used in lasers, laser devices, laser parts, etc., can solve problems such as large structural space, troublesome transmitter operation and positioning, and achieve the effect of improving input power and/or efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

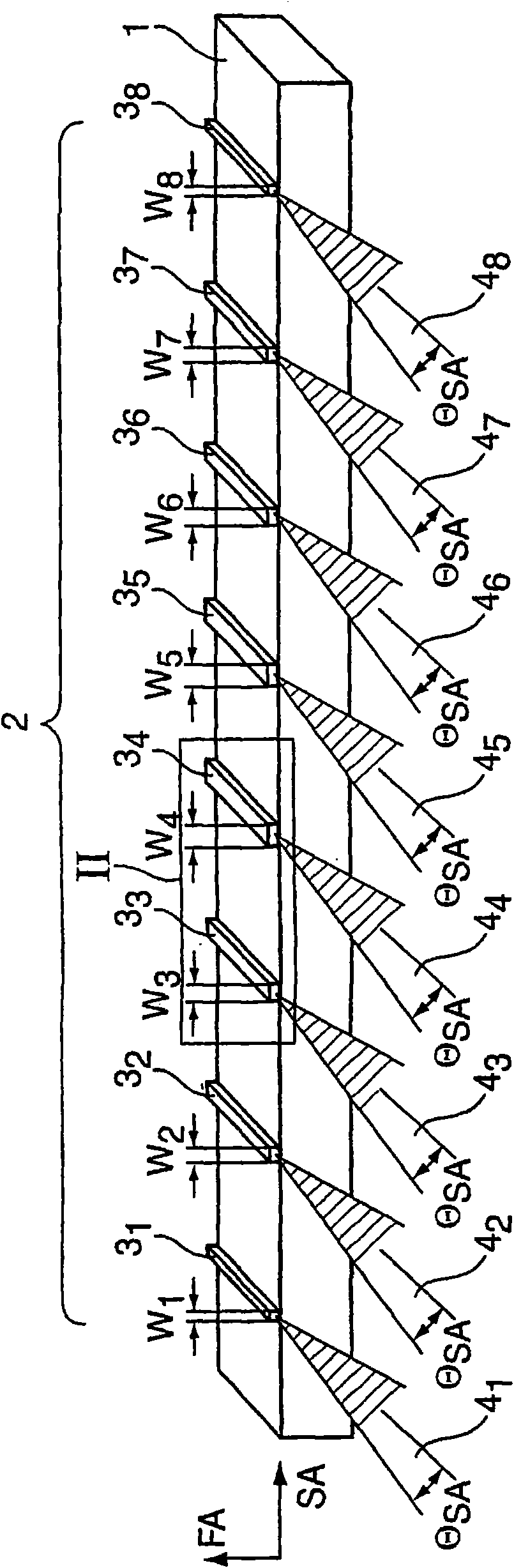

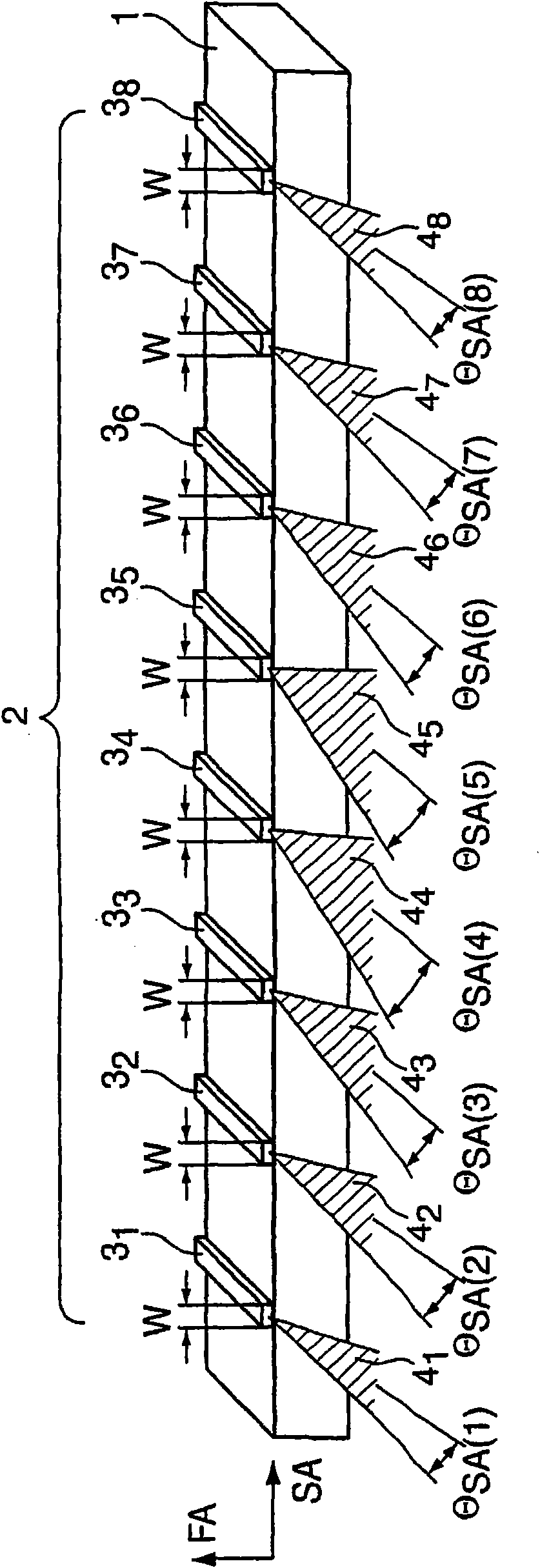

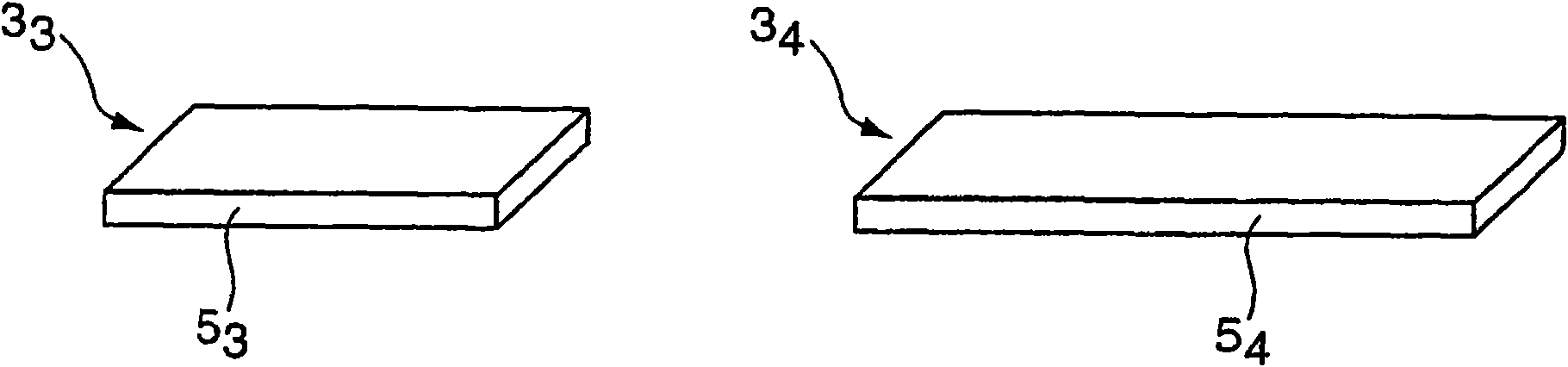

[0025] figure 1 The diode laser bar 1 shown in has a diode laser structure 2 with eight strip emitters 3 arranged in parallel next to each other 1 to 3 8 , these ribbon emitters with their SA axes in the same, at figure 1 The middle is oriented in the horizontal direction and are respectively disposed relative to each other in the horizontal direction. Ribbon Launcher 3 1 to 3 8 Several of them have different widths w in the SA direction 1 to w 8 , where the ribbon transmitter 3 1 to 3 8 The width of the diode laser structure 2 decreases, in particular mirror-symmetrically, from the center of the diode laser structure 2 towards the two edges of the diode laser structure 2 . Applicable: w 4 =w 5 >w 3 =w 6 >w 2 =w 7 >w 1 =w 8 . E.g. central launcher 3 4 、3 5 The width of is 50 to 500 μm, especially 100 to 200 μm. The emitter width decreases from one emitter to the other toward the edges by at most 50%, in particular at most 30%. The decrease in emitter width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com