Turbo molecular pump

A turbomolecular pump and stator technology, which can be used in pumps, pump components, axial flow pumps, etc., to solve problems such as reduced efficiency of turbomolecular pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

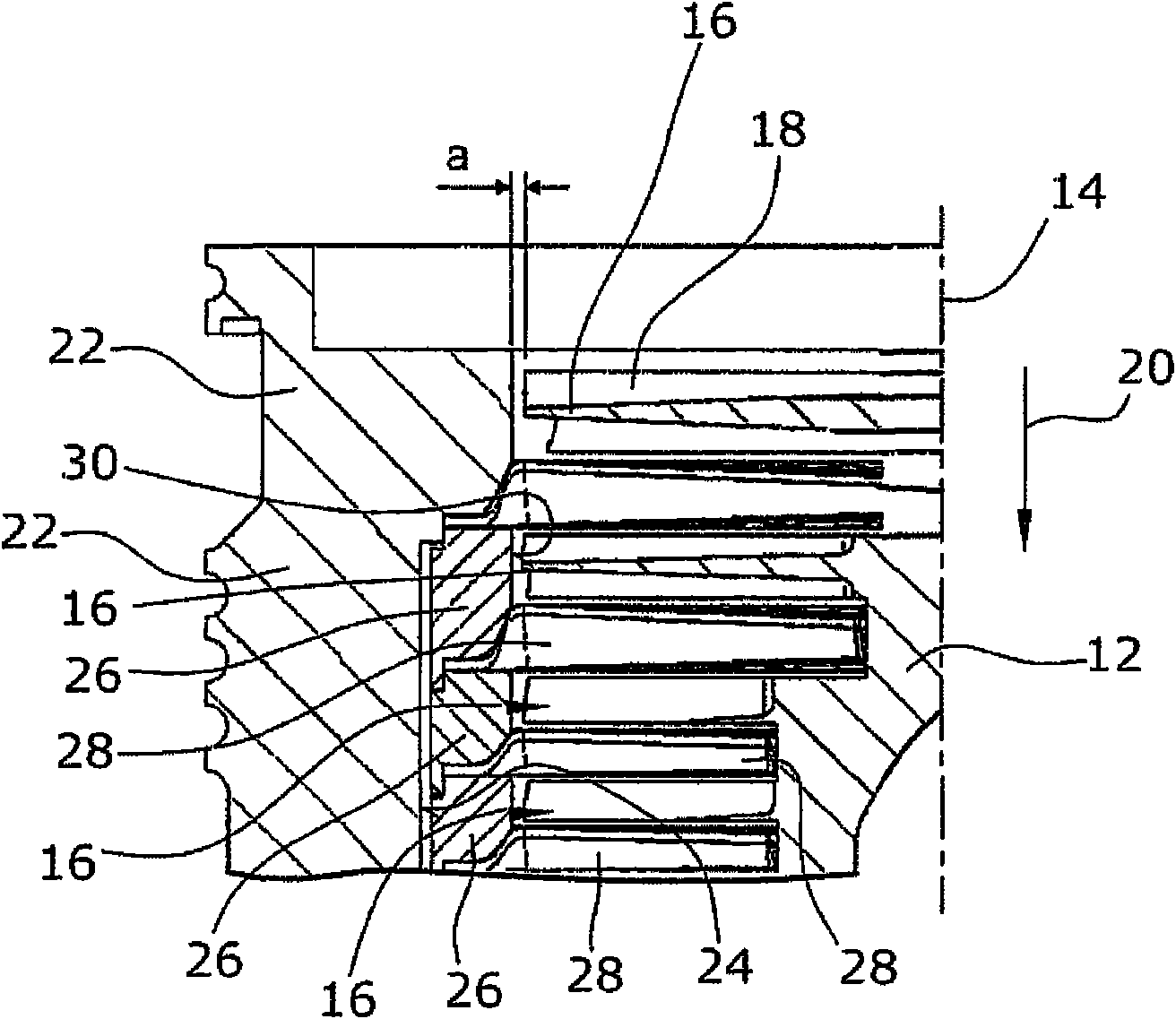

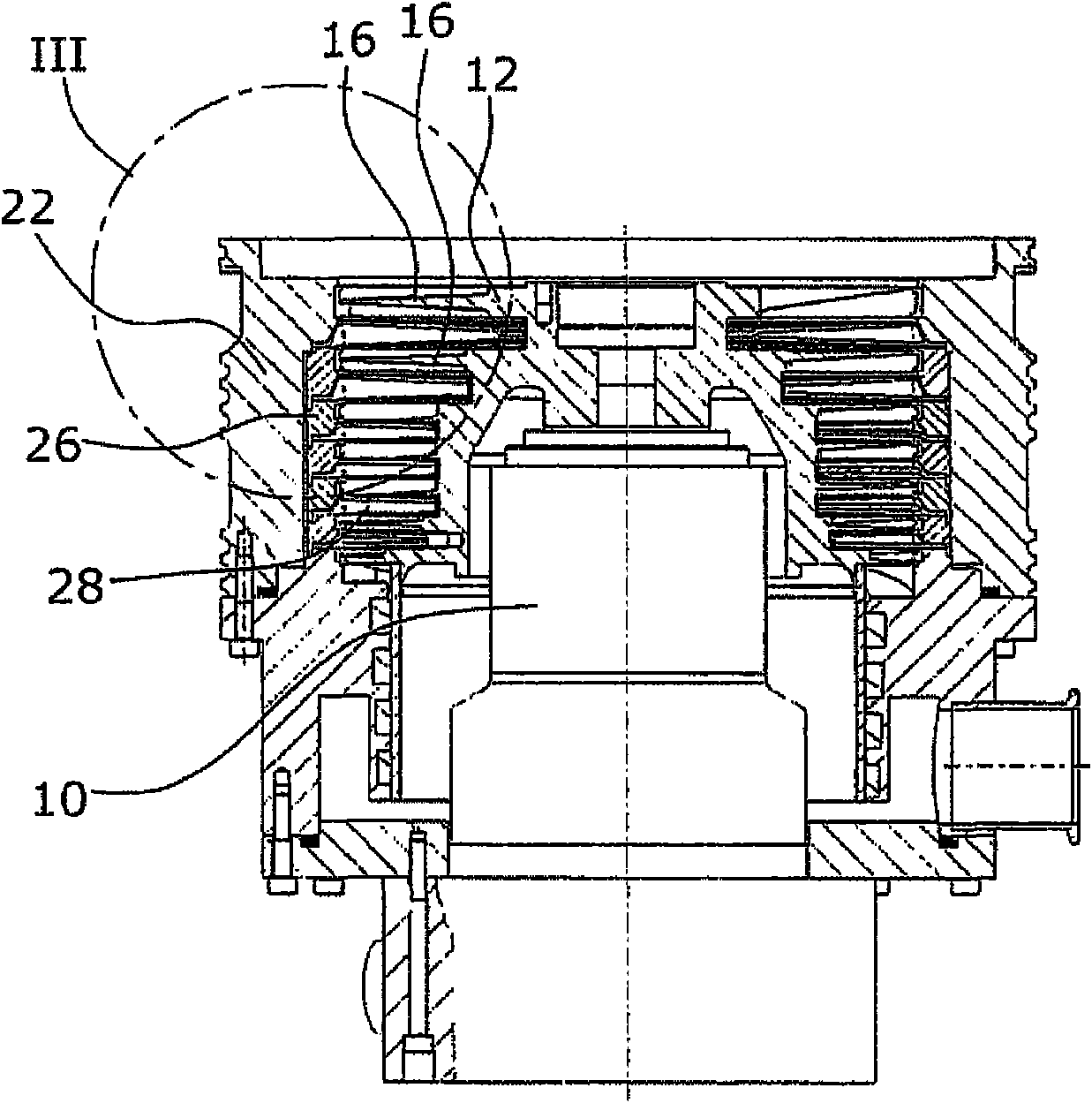

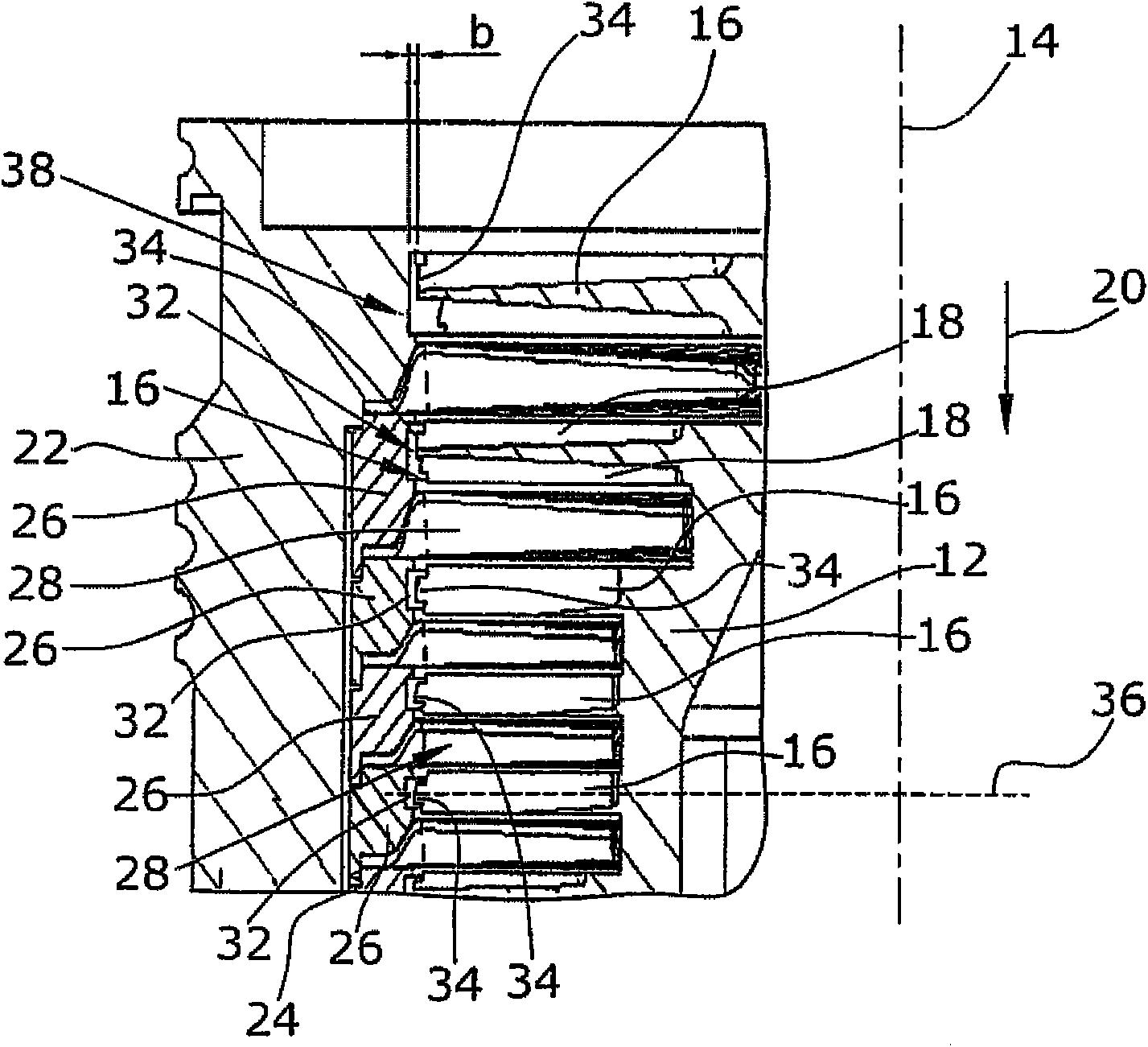

[0016] follow in figure 1 An embodiment of a turbomolecular pump according to the prior art is shown in , showing a drive shaft 10 ( figure 2 ) on the rotor 12. The rotor 12 has rotor vanes 16 extending radially with respect to the longitudinal axis 14 or the axis of rotation of the shaft 10 . Each rotor vane has a rotor blade 18 which is suitable so that in the gas to be conveyed parallel to the longitudinal axis, that is to say at figure 1 Downward in the direction of arrow 20 produces the main flow direction. The rotor 12 is arranged in a housing 22 , wherein the housing for accommodating the rotor has a cylindrical, optionally stepped, recess 24 .

[0017] Part of the rotor blade 16 is surrounded by a stator ring 26 . The stator ring 26 is arranged continuously in the longitudinal direction 14 and thus covers the inner side of the cylindrical groove 24 of the housing 22 . Arranged between adjacent stator rings 26 are stator disks 28 facing inwards in the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com