Device for culturing aerobic granular sludge and dedicated reactor thereof

A reactor and aeration device technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. Utilization and other issues, to achieve broad promotion value and application prospects, reduce the height of the reaction device, and facilitate cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

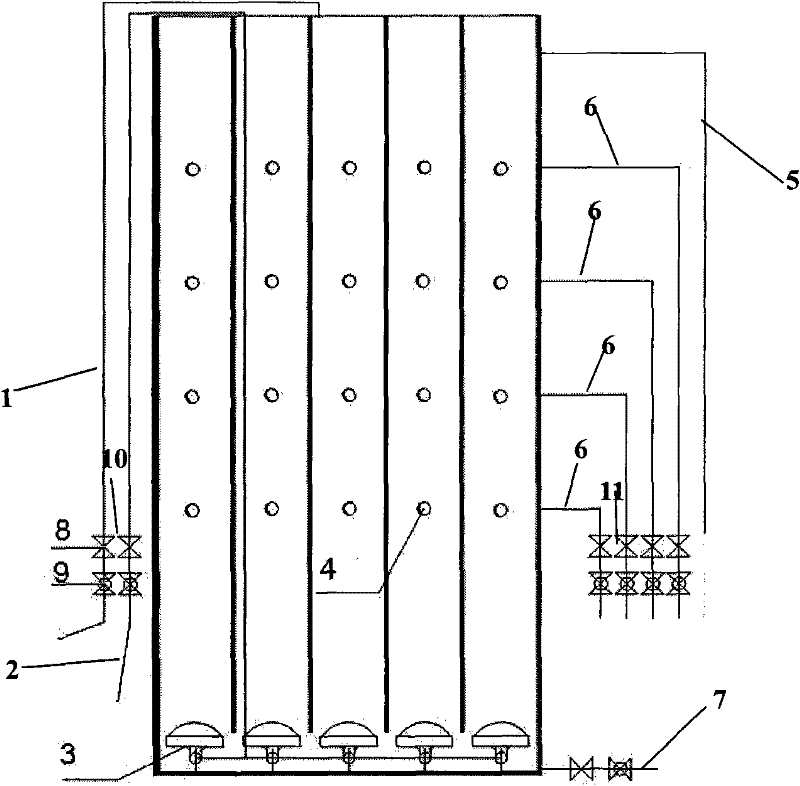

[0021] Embodiment 1, sequencing batch type activated sludge method reactor

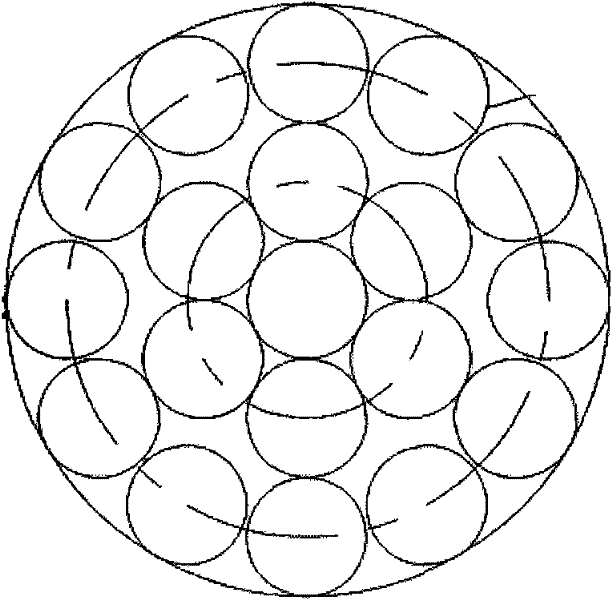

[0022] The sequencing batch activated sludge process reactor is composed of a closed shell, an aeration device arranged at the bottom of the closed shell and a tube bundle placed in the closed shell. The airtight casing is a cylinder, and the airtight casing is provided with an aeration hole, a water inlet hole, a mud discharge hole, four drain holes and an overflow port. One end of the aeration pipe 2 is airtightly connected with the aeration device through an aeration hole, and the other end is provided with a control valve 9 and an intake valve 10, and is exposed to the air. One end of the water inlet pipe 1 is airtightly connected with the airtight casing through the water inlet hole, and the other end is provided with a control valve 9 and a water inlet valve 8, and is airtightly connected with the water inlet system. One end of the four drain pipes 6 is airtightly connected with the airtight ca...

Embodiment 2

[0023] Embodiment 2, the device of cultivating aerobic granular sludge

[0024] The device for cultivating aerobic granular sludge consists of a water inlet system, the sequencing batch activated sludge process reactor of Example 1, drainage, sludge discharge system and control system. The water inlet system, the drainage system and the sludge discharge system are connected with the sequencing batch type activated sludge process reactor in the manner described in Example 1. The control system consists of a time controller and online monitoring equipment for operating parameters (on-line DO determination, on-line sludge concentration measurement, and on-line pH measurement). The time controller is connected with the water inlet system, aeration device and drainage system to precisely control each period of the SBR reaction, and at the same time integrate online monitoring equipment to dynamically understand and respond to abnormal conditions of the reaction system.

[0025] Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com