Method and system for controlling alternating movement of central shuttle

A technology of alternating movement and control method, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., which can solve the problems of high mechanical load requirements and heavy workload of the ring hook shaft, so as to improve production efficiency and improve embroidery products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

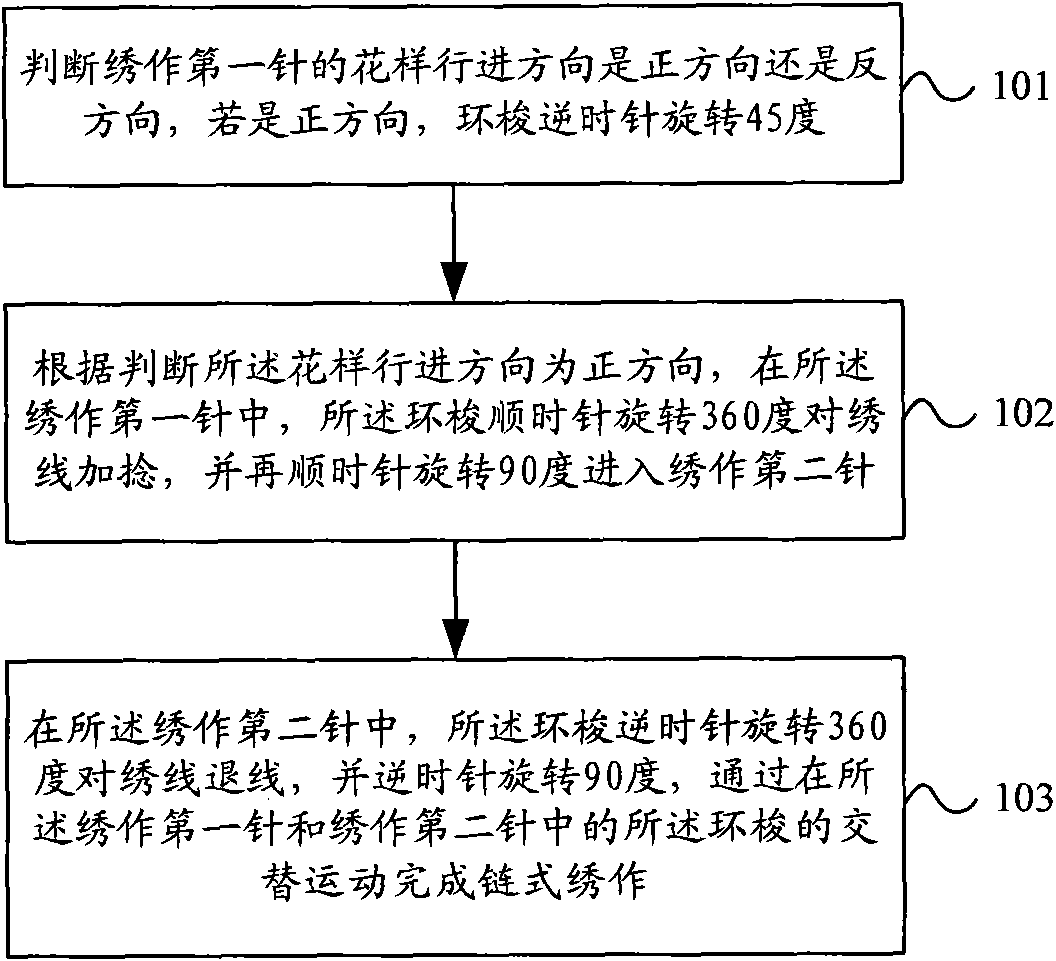

[0023] figure 1 It is a flow chart of the method for controlling the alternate motion of the shuttle in the present invention. like figure 1 As shown, the shuttle alternate motion control method of the present embodiment includes:

[0024] Step 101, judge whether the direction of the pattern to be embroidered for the first stitch is the forward direction or the reverse direction, and if it is the forward direction, the loop shuttle is rotated 45 degrees counterclockwise.

[0025]At the beginning of chain embroidery on embroidered cloth, first judge whether the pattern of the first stitch to be embroidered is in the forward direction or in the reverse direction. If it is in the forward direction, the ring hook shaft is rotated 45 degrees counterclockwise to drive the ring shuttle to rotate 45 degrees counterclockwise....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com