Pressure sensor with diaphragm and depth gauge incorporating such sensor

A pressure sensor and diaphragm technology, applied in the field of depth gauges, can solve problems such as limiting the elastic deformation of the diaphragm and achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

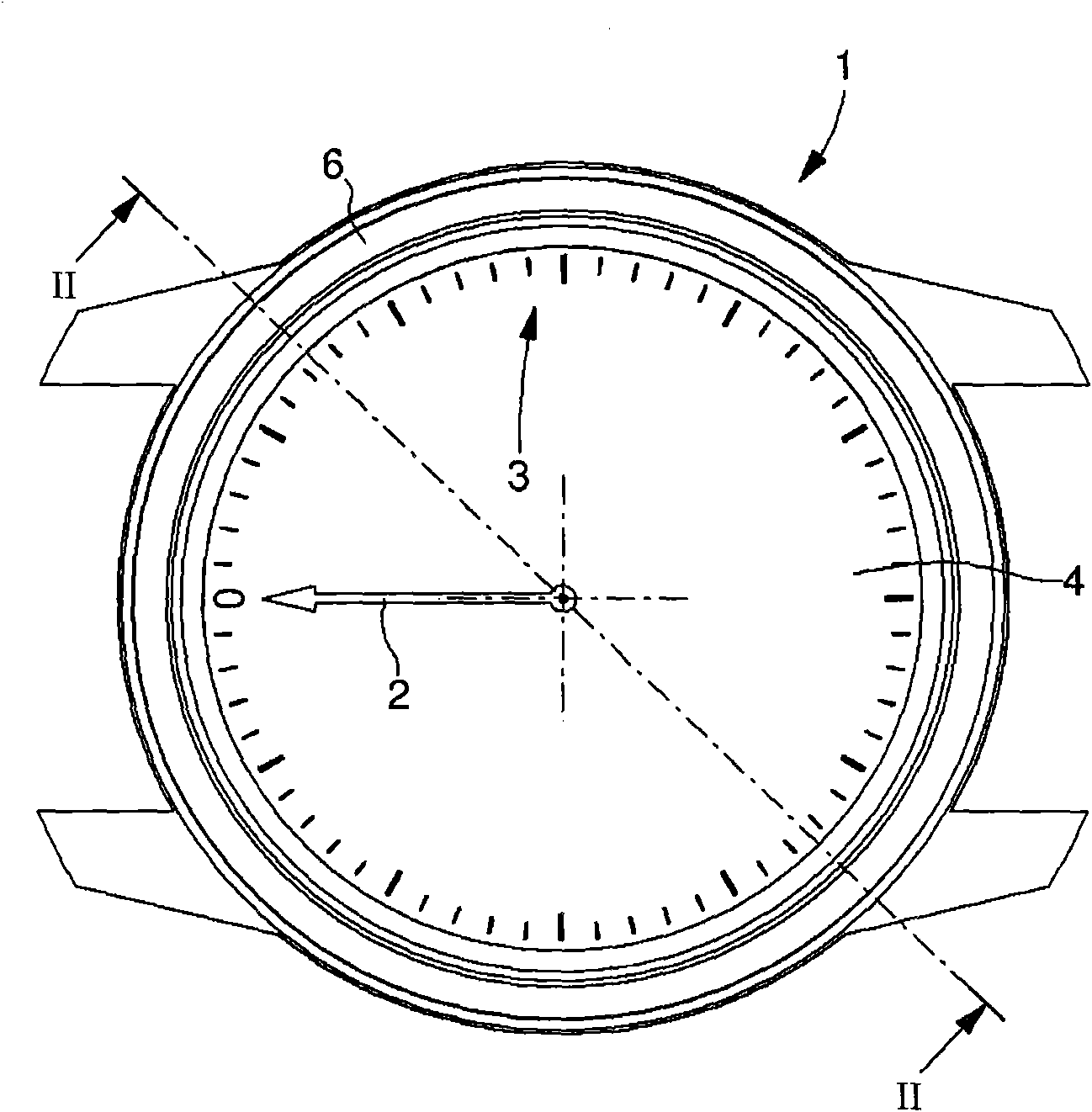

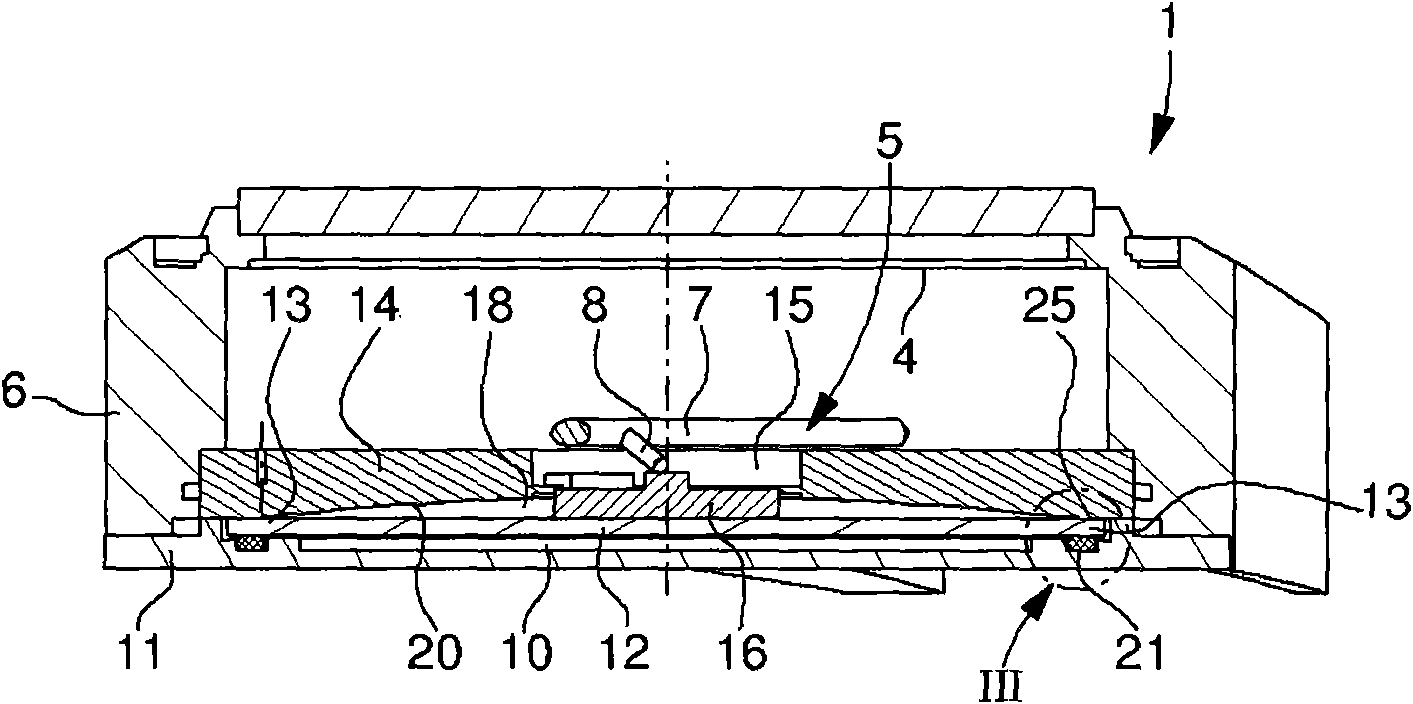

[0015] Figure 1-3 A depth gauge 1 is schematically shown worn on a diver's wrist using a strap not shown, for indicating the depth of the water via a pointer 2 using a pressure sensor housed in a depth gauge housing 6 5 to rotate relative to scale 3 of dial 4. The pressure sensor is connected to the pointer 2 by means of a mechanical transmission, in particular a rotating shaft 7 with a transverse probe 8 . It should be noted that the depth gauge 1 can be combined with a watch inside the same case, but this is not essential.

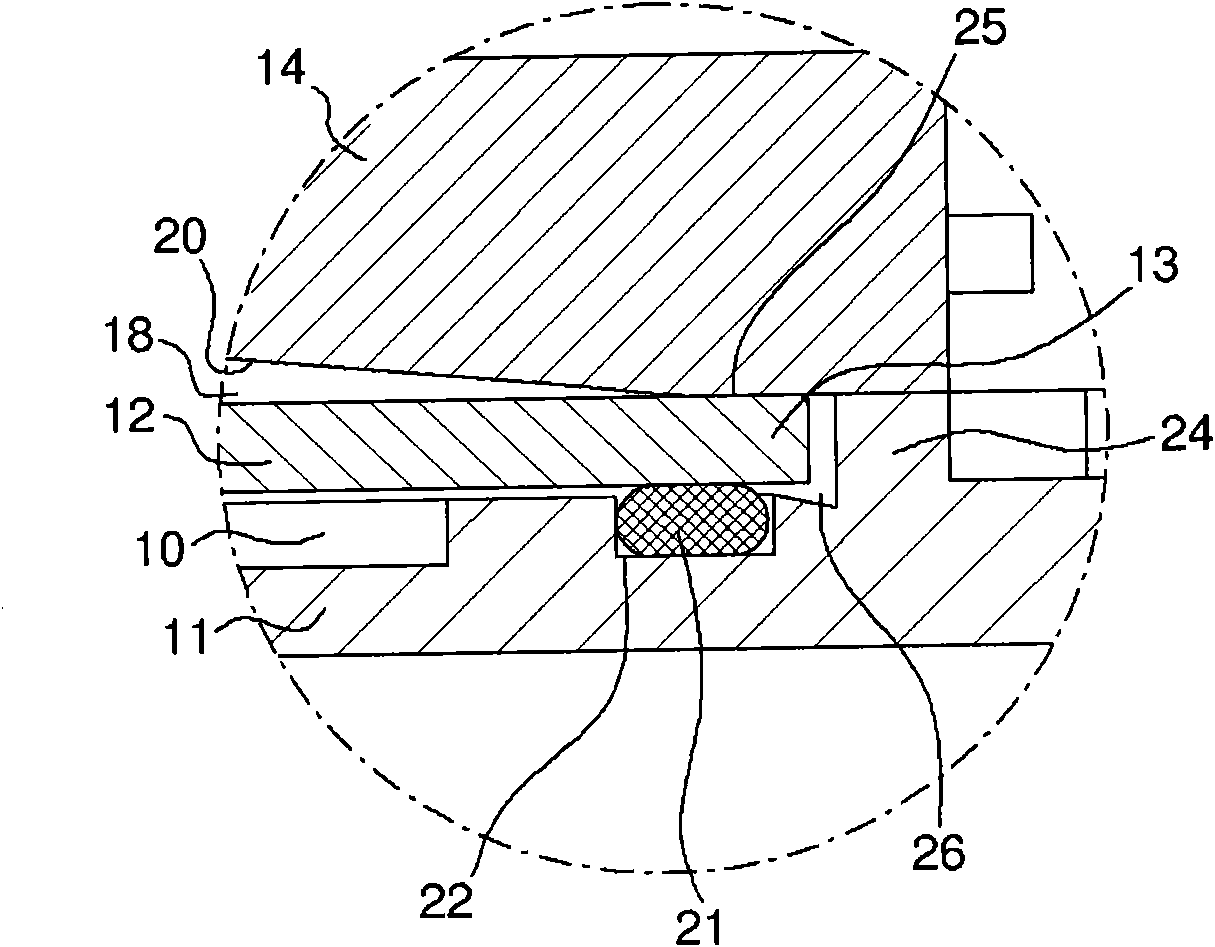

[0016] The pressure sensor 5 is mounted on a rear cover 11 of the housing, which generally forms the main body of the sensor. The sensor is arranged above a pressure chamber 10 formed in the rear cover 11 and communicates with the exterior of the housing via a hole (not shown) so that the fluid contained in the chamber is subjected to a pressure mainly around the depth gauge. The pressure sensor 5 has a flat annular diaphragm 12 whose peripheral regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com