Lock ring type inertia synchronizer

A synchronizer and lock-ring type technology, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of large shifting torque and loud noise, shorten the synchronization time, and achieve light and fast shifting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

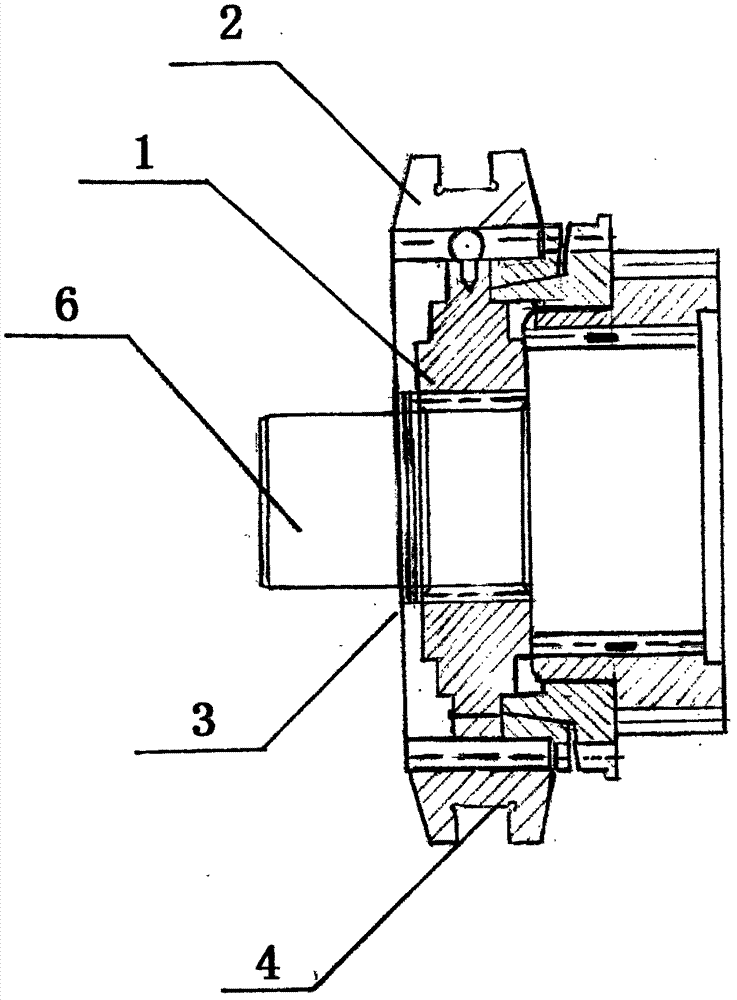

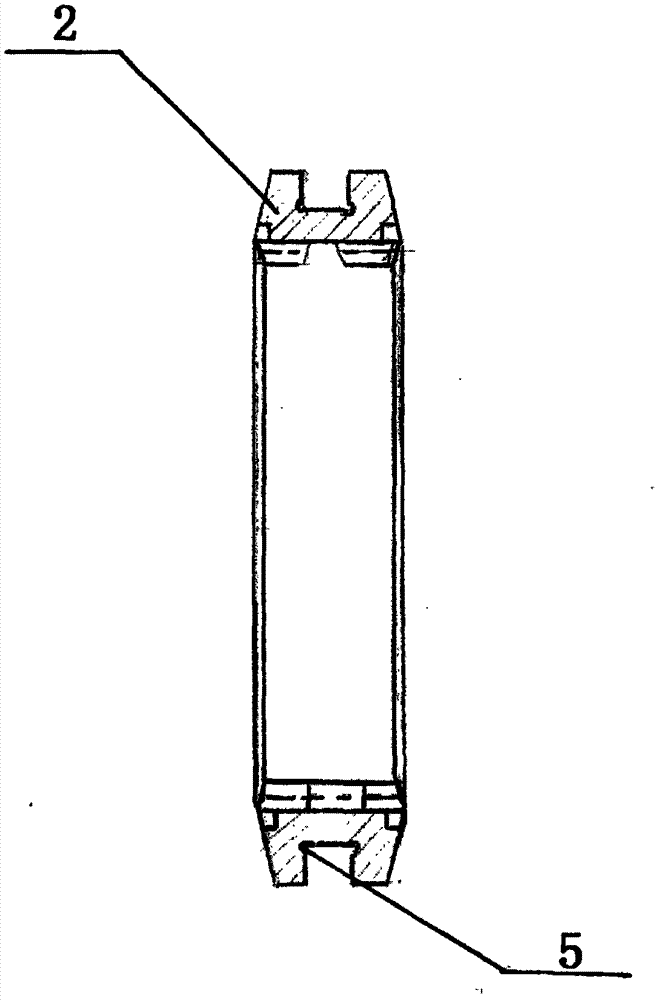

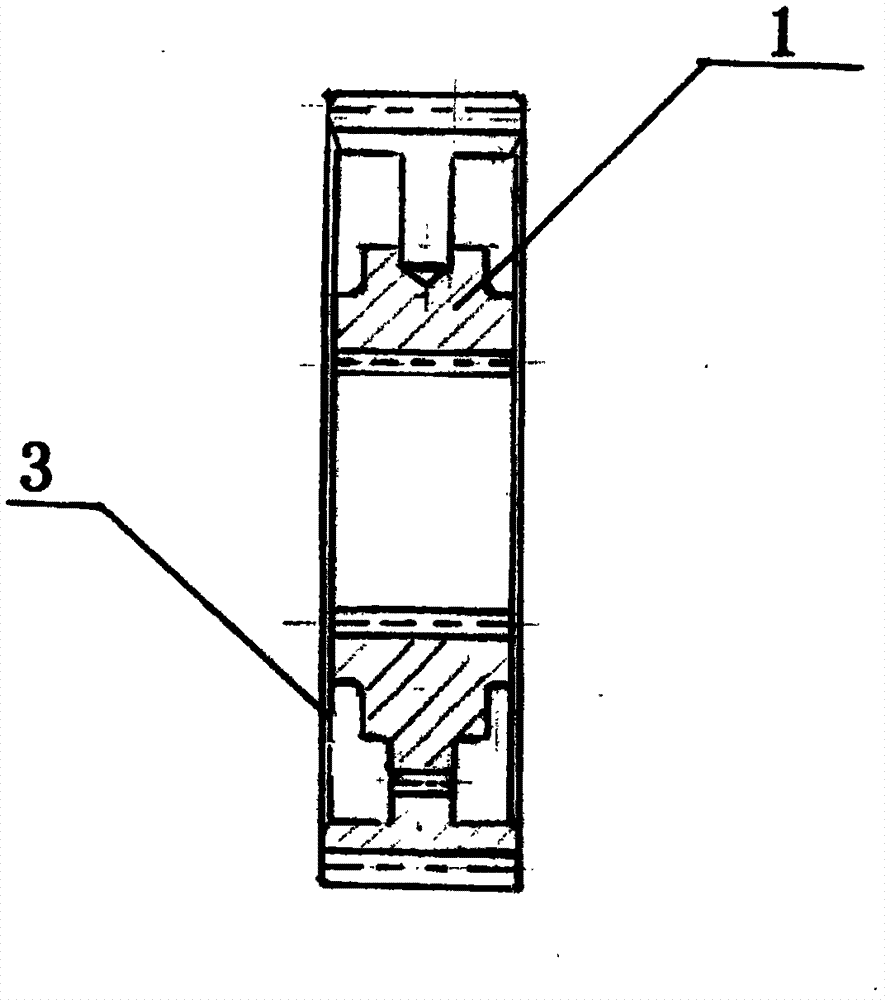

[0010] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a lock ring type inertia synchronizer, which includes a gear hub 1 , a gear ring 3 and a sliding gear sleeve 2 . There are 18 standard involute splines in the inner hole of the gear hub 1 to cooperate with the second shaft 6 of the transmission. One end surface of the gear hub 1 is riveted into three equal parts by rivets at 120° to press the gear ring 3. The ring 3 is riveted on the end surface of the gear hub 1 by rivets to form a gear hub assembly with the gear hub 1, so that the sliding gear sleeve 2 can shift gears in one direction. The outer circle of the sliding gear sleeve 2 is provided with a shift fork groove 4 for shifting gears, and an oil storage tank 5 is arranged on both sides of the bottom diameter of the shift fork groove 4, which improves the lubrication between the contact surface of the shift fork and the shift fork groove 4 Conditions, improve the performance and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com