Dust-protected hand-held power tool

An electric tool and hand-held technology, applied in the field of hand-held electric tools, can solve the problems that dust can no longer be removed, electric drive parts are damaged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

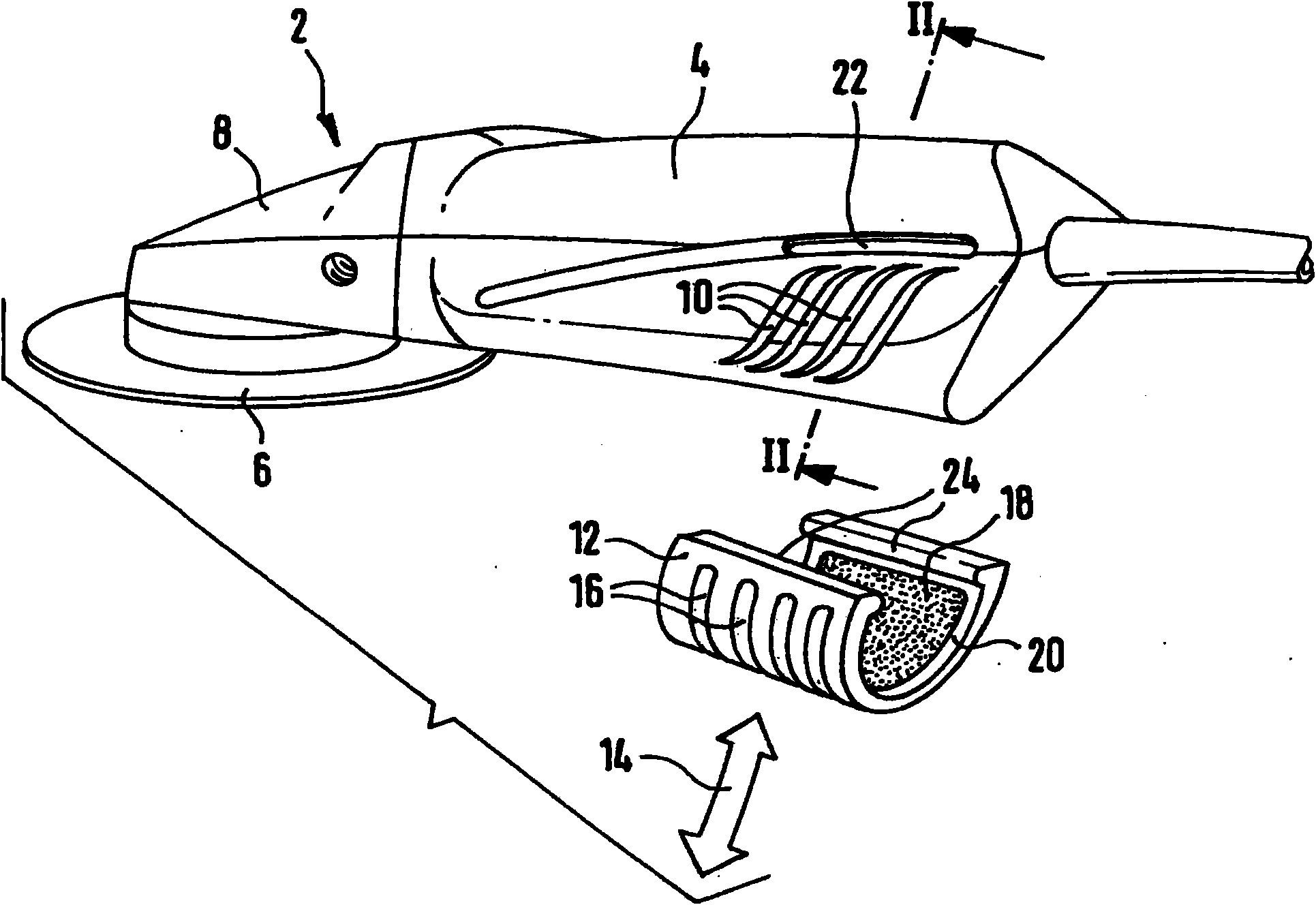

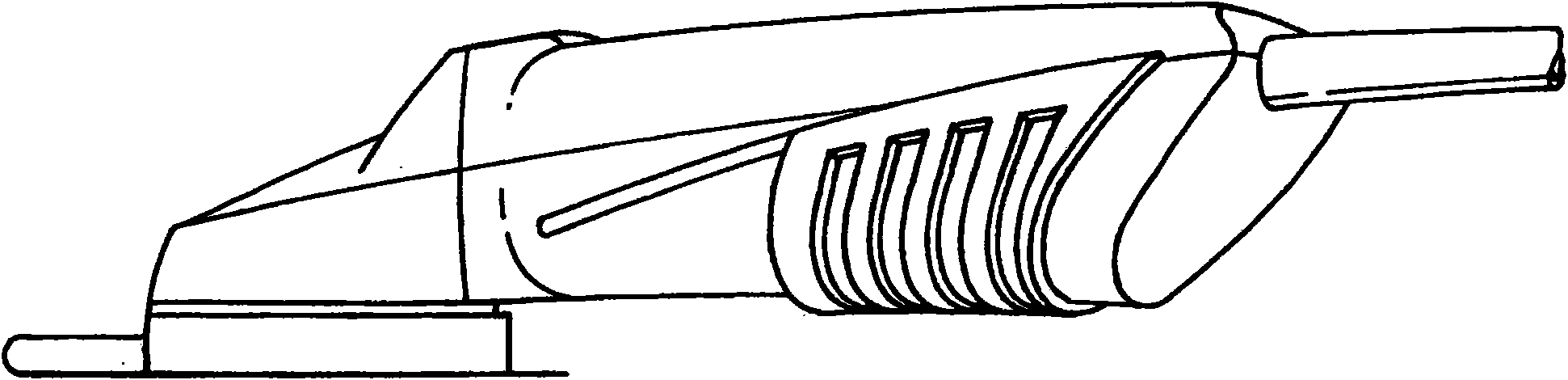

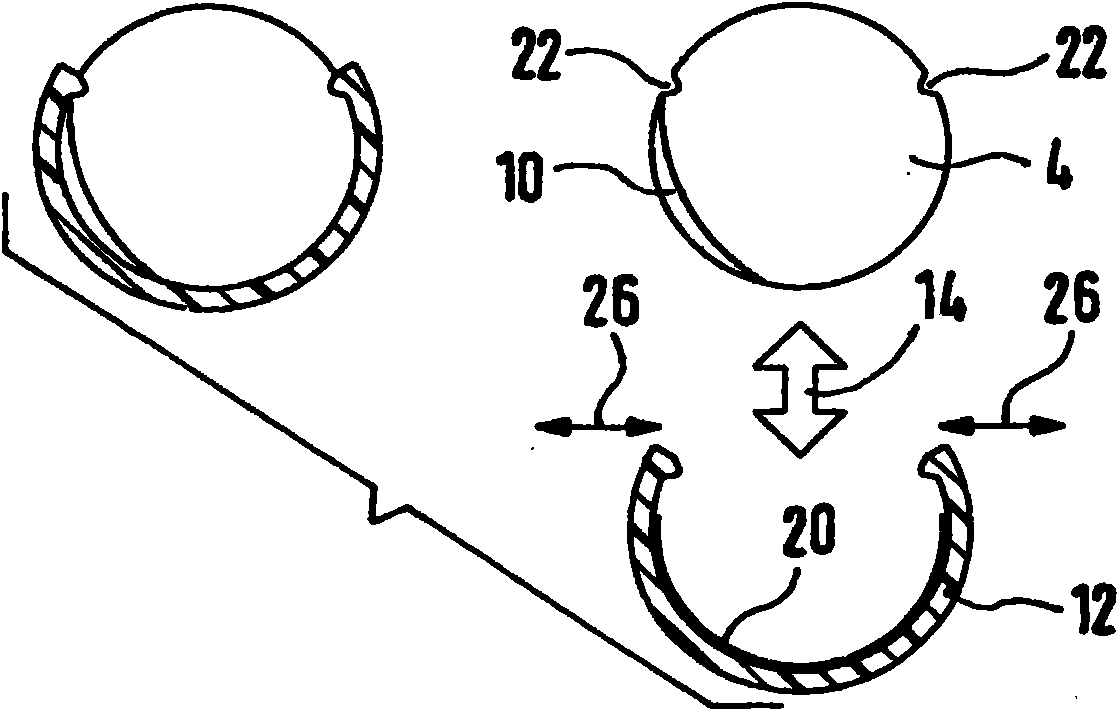

[0017] Figure 1 and figure 2 A hand-held electric tool 2 in the form of an angle grinder is shown, which has a housing 4 which accommodates electric drive components and which also forms the handle part of the hand-held electric tool 2 . The housing 4 comprises two housing half-shells made of plastic which lie against each other in the longitudinal parting plane. A typically metallic gear housing part 8 is attached to the housing 4 in the direction of the tool 6 . Air inlet openings 10 are formed in the central region to the rear region of the housing 4 , through which a cooling air flow is formed, which makes the electric drive components inside the housing 4 work on the hand-held electric tool 2 . to cool down. The cooling air flow sucked into the interior of the housing 4 through these air intake openings 10 is discharged again at other points, typically in the region of the transition to the transmission housing part 8 .

[0018] In the region of the section of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com