Medical heat exchanger, manufacturing method thereof and artificial lung device

A heat exchanger and medical technology, which is applied in the direction of suction equipment, dialysis system, blood circulation treatment, etc., can solve the problems of greater influence of flow rate and lower heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

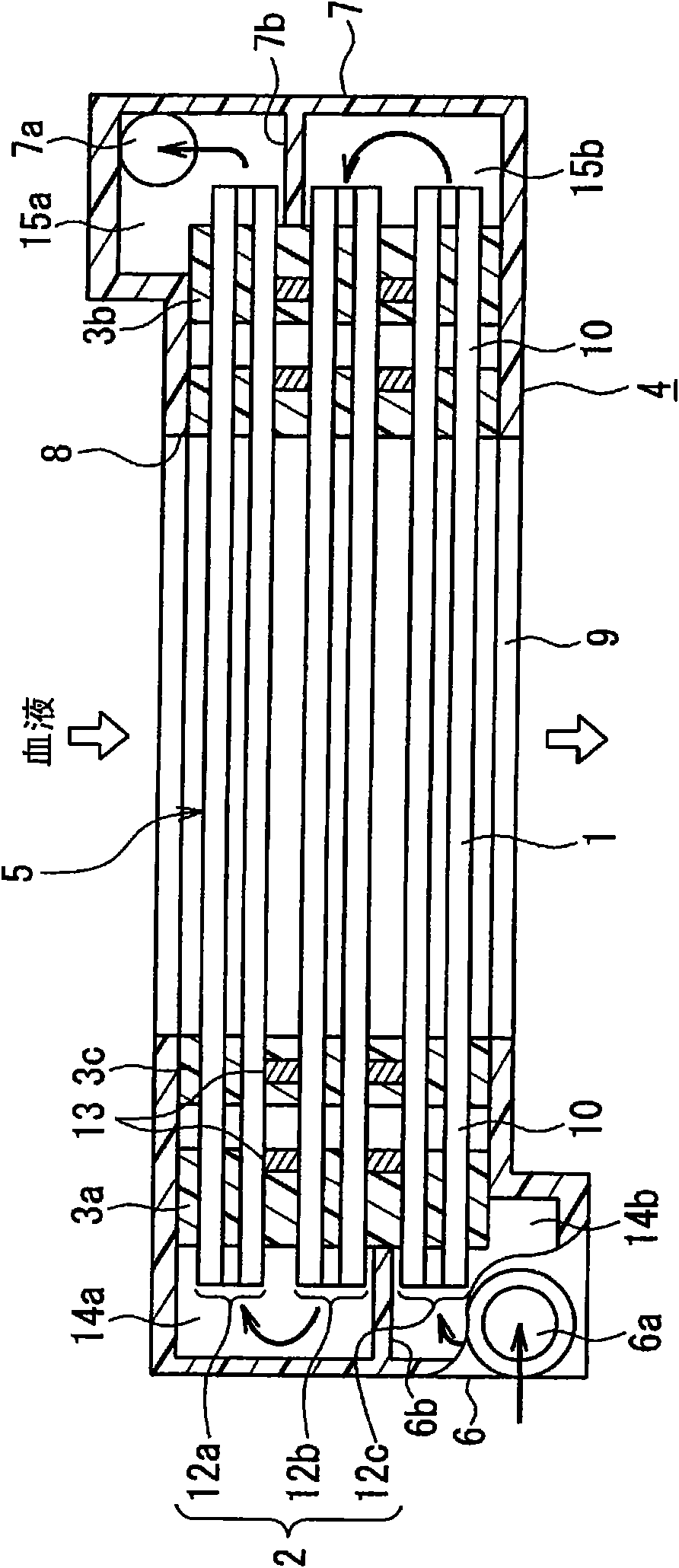

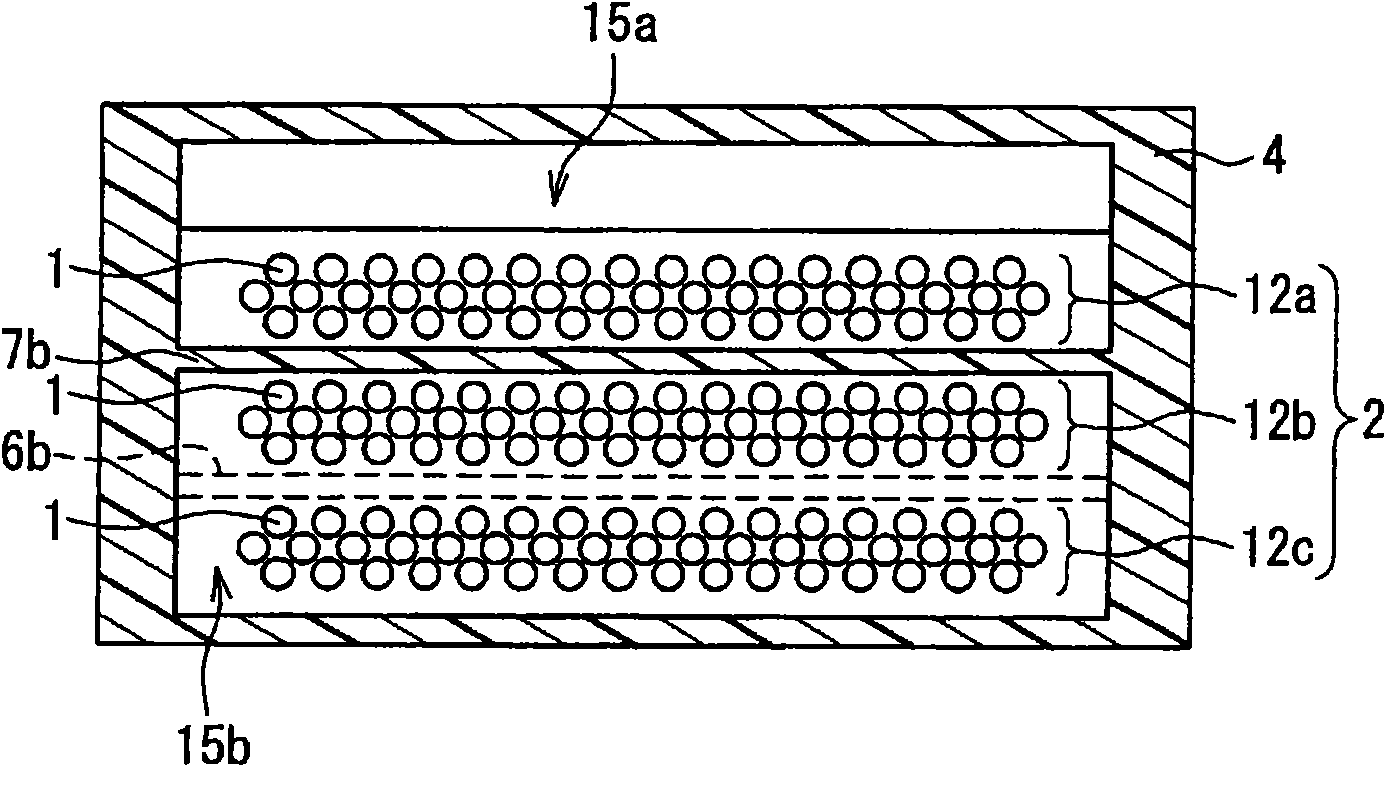

[0084] Figure 1A It is a plan view showing the medical heat exchanger according to Embodiment 1. Figure 1B yes Figure 1A A-A sectional view of, Figure 1C yes Figure 1A The B-B section view. This heat exchanger is provided with: a thin tube bundle 2, which is composed of a plurality of heat transfer thin tubes 1 for circulating a heat medium liquid, that is, hot and cold water; sealing members 3a to 3c, which seal the thin tube bundle 2; and a housing 4 for housing the above-mentioned members. .

[0085] A plurality of thin heat transfer tubes 1 are arranged and stacked in parallel to form a thin tube bundle 2 , and cold and hot water flow in the inner cavity of each thin heat transfer tube 1 . A blood flow channel 5 having a circular cross section is formed in the longitudinal center of the thin tube bundle 2 of the center sealing member 3c, and functions as a heat exchange region for circulating blood, which is a liquid to be heat exchanged. The blood passing throu...

Embodiment approach 2

[0107] Same as Embodiment 1, refer to Figure 1A ~ Figure 1C A medical heat exchanger according to Embodiment 2 will be described. This embodiment is a case where a plurality of thin tube bundle units are laminated in the blood flow direction, that is, in the longitudinal direction, and has a longitudinally folded structure, and is used as a member for forming spaces between the respective stages of the first to third thin tube bundle units 12a to 12c. The structure of the spacer 13 will be described in detail. The other structures are the same as those in Embodiment 1, and repeated descriptions are omitted.

[0108] As described in the description of Embodiment 1, in order to form a longitudinal folding structure, the flow chamber for introducing cold and hot water into the header 6 needs to be divided into the upper flow compartment 14a and the lower flow compartment 14b through the partition wall 6b, and the cold and hot water must be separated through the partition wall 7...

Embodiment approach 3

[0116] Figure 7A It is a plan view showing the medical heat exchanger according to Embodiment 3. Figure 7B yes Figure 7A C-C section view. Figure 7A The shape of the D-D section is with Figure 1C The same applies to the first embodiment shown. This embodiment is characterized in that, as Figure 7B As shown, the insertion member 20 is disposed between the respective stages of the first to third capillary bundle units 12 a to 12 c in the blood flow channel 5 . Therefore, the same reference numerals are assigned to the same elements as those in the first and second embodiments, and redundant descriptions will be omitted.

[0117] As described in Embodiment 2, if spacers 13 are installed between the multi-stage narrow tube bundle units 12a to 12c to form intervals of a predetermined length between each stage, it is possible to sequentially distribute hot and cold water in a desired order. By the simple structure of each thin tube bundle unit 12a-12c. When using this s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com