Amphibian

An amphibious, vehicle technology, applied in amphibious vehicles, vehicle parts, wheels, etc., can solve the problem of limited width given width and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

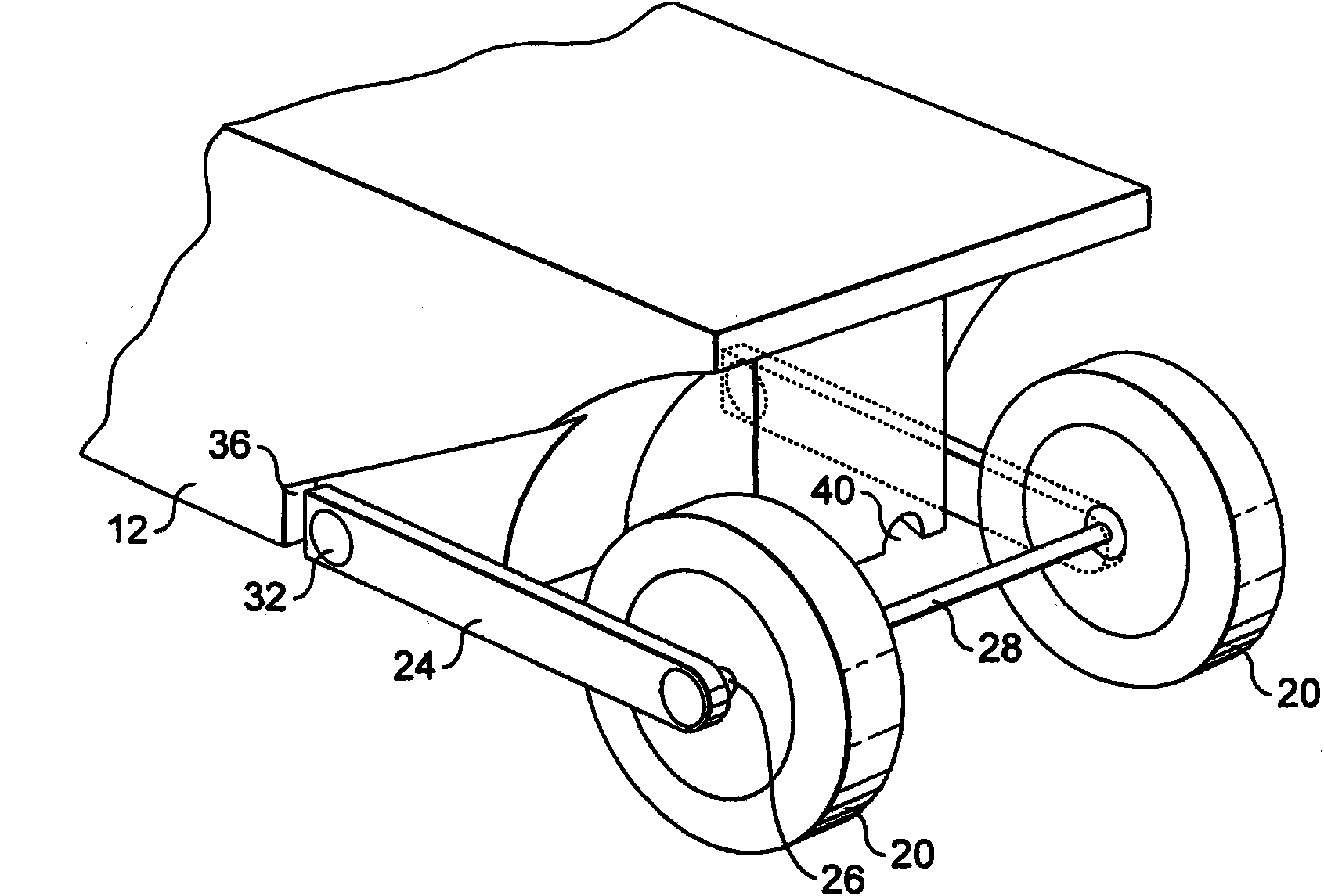

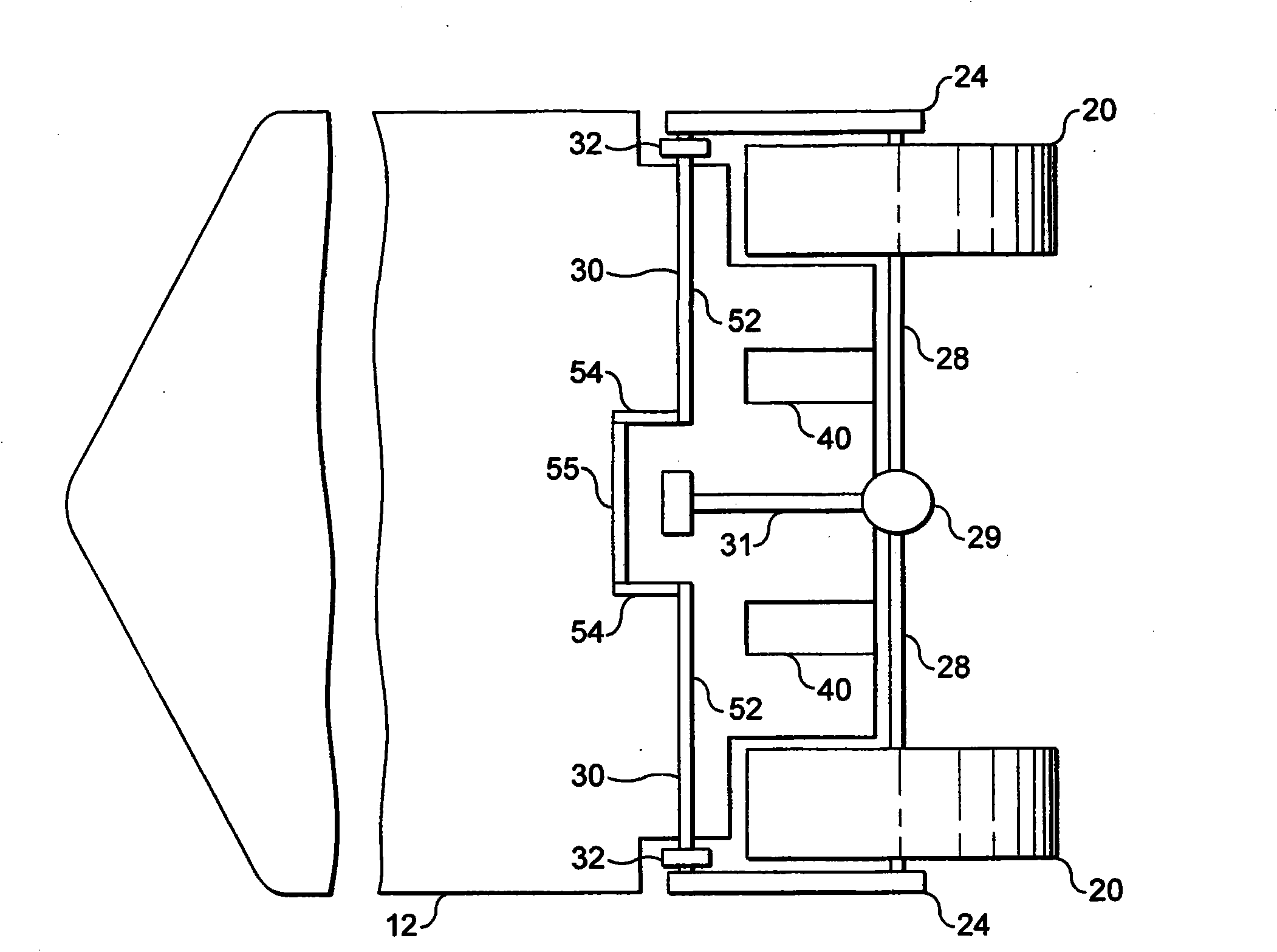

[0009] See attached picture, figure 1 with 2 An amphibious vehicle 10 according to the present invention is shown. The amphibious vehicle 10 includes a hull 12 which is a buoyant shell and has a pair of rear wheels 20. The hull 12 is V-shaped in vertical cross section. The amphibious vehicle 10 also has one or more front wheels (not shown).

[0010] The vehicle 10 includes a motor (not shown) or a similar power source to provide power to the rear wheels 20 through a transmission device. Alternatively, the motor may only provide power to the front wheels, or may provide power to the front and rear wheels.

[0011] The rear wheel 20 is connected to the hull 12 through a suspension assembly 22. The suspension assembly 22 includes a pair of trailing arms 24 extending rearward from the hull 12. The towing arm is rotatably connected to the chassis of the vehicle (located within and supporting the hull 12) at the pivot 32.

[0012] The rear wheels 20 are rotatably installed inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com