Non-outflow type gas pressure/volume control device

A volume control and gas pressure technology, applied in liquid/fluid solid measurement, measurement device, optical device, etc., can solve problems such as sealing of moving parts, and achieve the effect of preventing leakage, high measurement accuracy and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

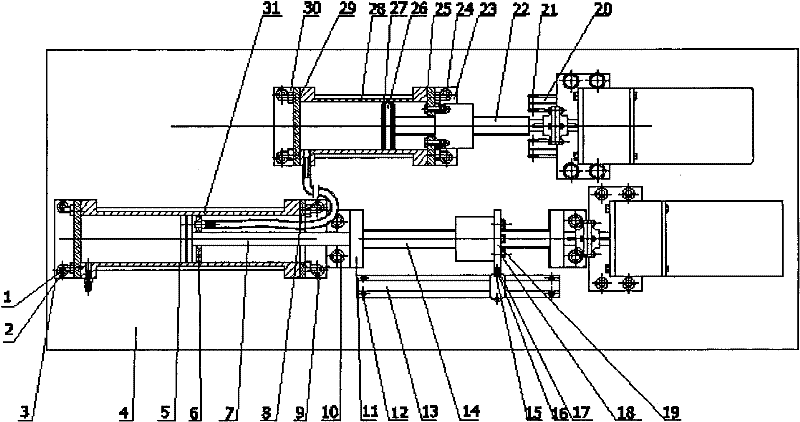

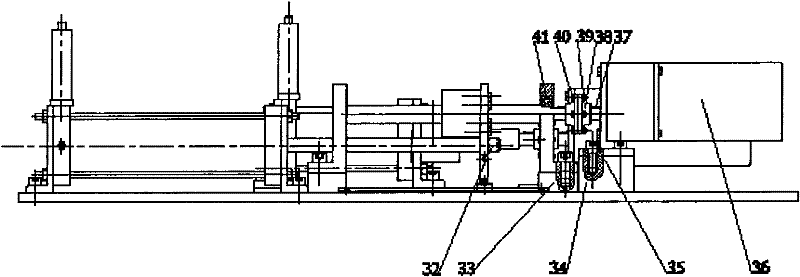

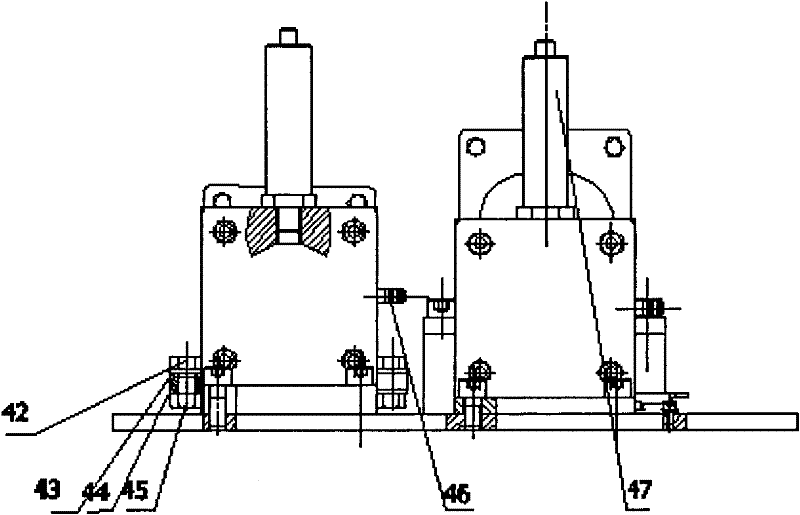

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0016] as attached Figure 1~4 As shown, the parts are cleaned with kerosene during assembly, and the mating surface is oiled after drying. The unprocessed surface of each part should be cleaned, the burrs should be removed, and the anti-rust paint should be dipped; When the deceleration servo motor 36 of the cylinder 31 is in operation, the leading screw of the ball screw 14 is driven to rotate. Since the push plate 19 connected to the rear end of the nut is connected with the grating ruler 13 through the connecting rod 17, the push plate 19 will move linearly, thereby driving The main cylinder piston rod 7 fixed on the lower side of the baffle moves, so that the main cylinder piston 5 moves, compresses the gas in the main cylinder 31, and generates pressure; at the same time, the deceleration servo motor 36 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com