Clean operating room with air cleaning and conditioning system with intelligent adjustment and control

An air-conditioning system and operating room technology, applied in the field of clean operating rooms, can solve the problems of large load difference, only running, stopping, temperature and humidity display, high energy waste, etc. The effect of negative heat and cold saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

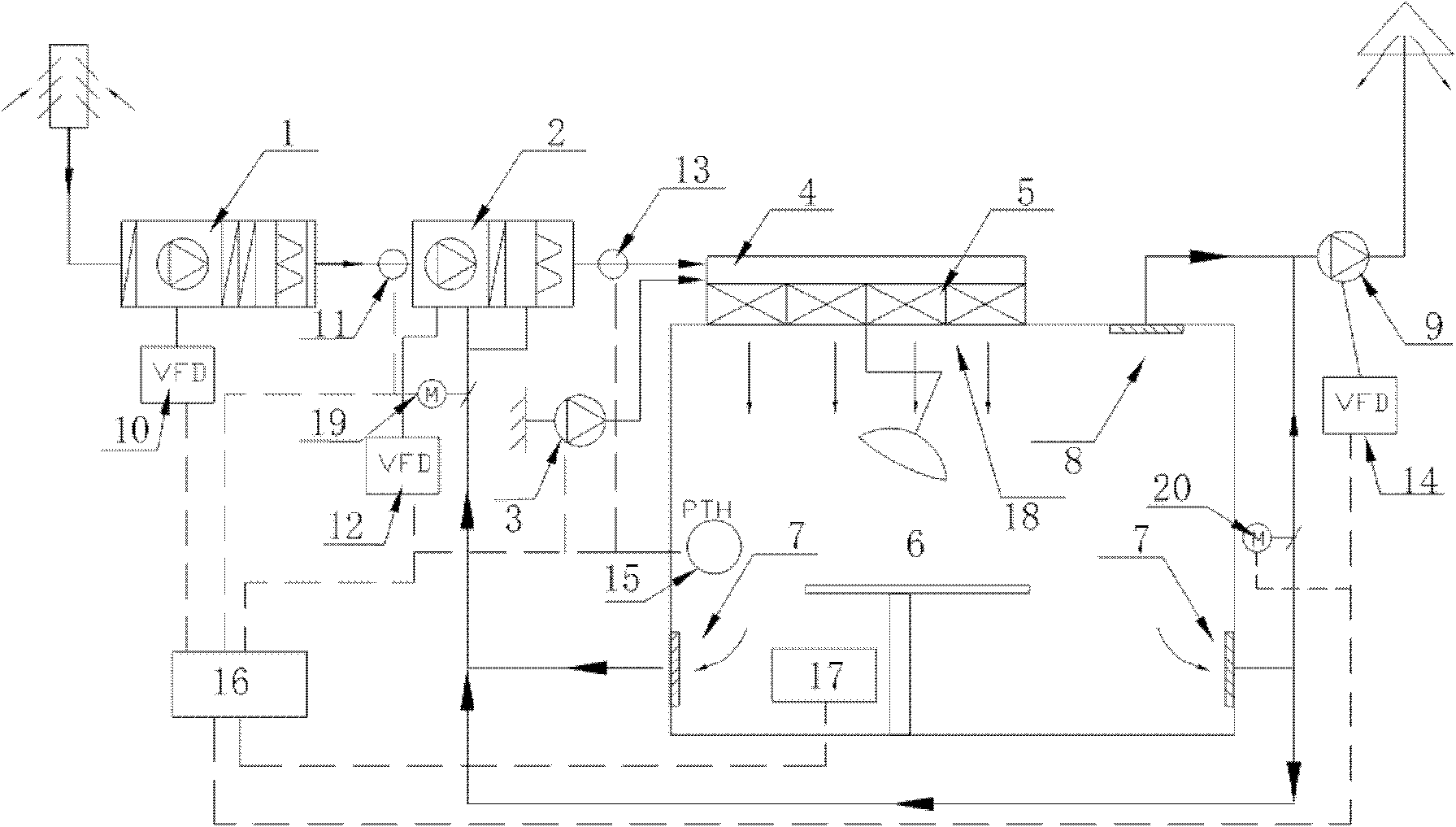

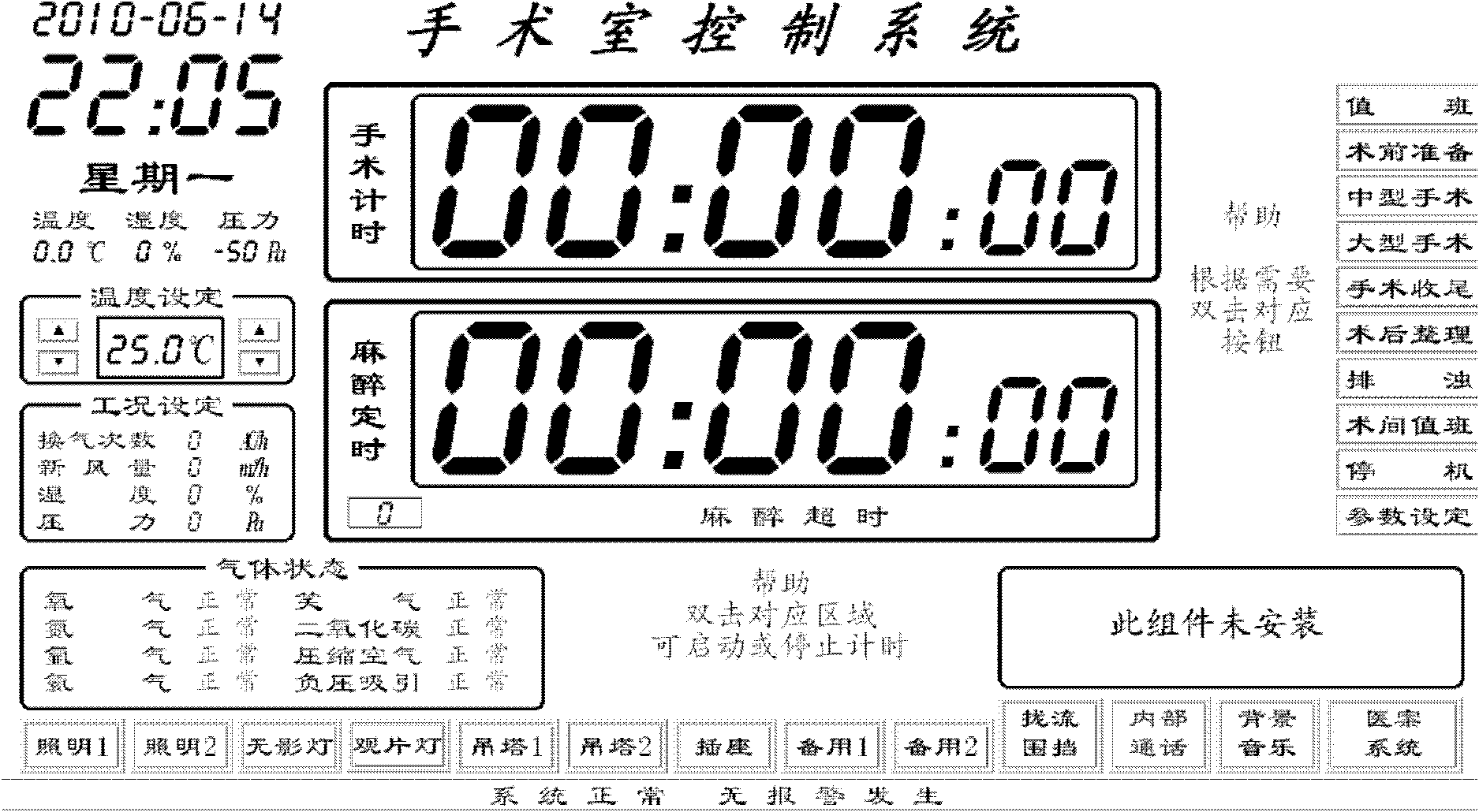

[0018] A clean operating room with an intelligent control and purification air-conditioning system, including a sterile clean space 6 and an air-conditioning purification and ventilation system, the top of the sterile clean space is provided with an air exhaust port 8, and the opposite side walls are provided with a plurality of air return ports 7. The aseptic clean space is equipped with a combination sensor 15 of temperature, humidity and pressure difference and a control unit 17. The control unit is an embedded computer control system with a large screen display. The operation diagram of the control panel is shown in figure 2 . An input port 18 for regulated and purified air is installed on the top of the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com