Rotary structure mold of complicated curved-surface component and stripping/closing method thereof

A technology of rotating structure and complex curved surface, which is applied in the field of complex curved surface parts rotating structure mold, can solve the problem of low automation of mold release and clamping, and achieve the effect of improving efficiency and ensuring the quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

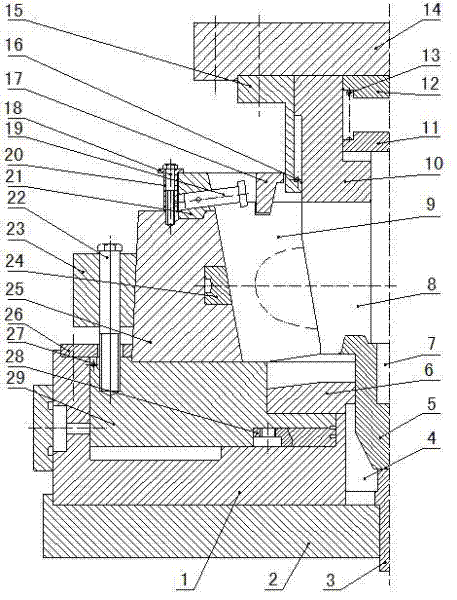

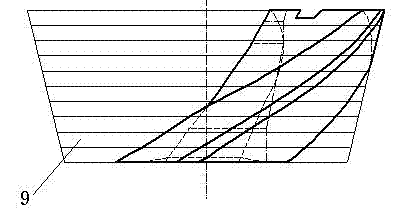

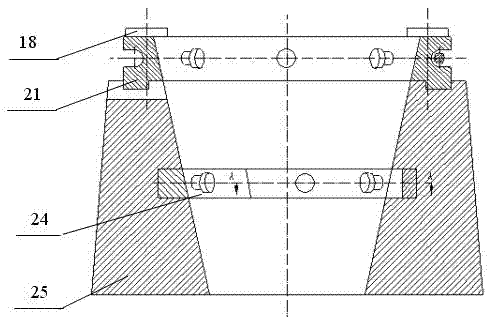

[0030] figure 1 It is a half-side cross-sectional view of the complex curved surface part rotation structure mold structure of the present invention. In the mold of the following embodiment structure, there are three petal block assemblies 9 and three-point arc fastening rings 24 respectively, and the rest of the mold is a symmetrical structure, including connection Fixing part, ejector mechanism part, lower mold release and clamping structure part, upper mold pressurization and mold release and clamping auxiliary part.

[0031] The connection and fixing part includes the upper top plate 14 and the lower bottom plate 2, the upper top plate 14 is connected with the movable beam of the hydraulic press, the lower bottom plate 2 is fixed on the working table of the hydraulic press, the lower bottom plate 2 is provided with a seat compartment 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com