Carrying head of electronic components

A technology of electronic components and mounting heads, which is applied in the direction of electrical components, electrical components, circuits, etc., can solve the problems of resistance generated by the axis of the suction nozzle, large sliding resistance, etc., and achieve the effect of rapid up and down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

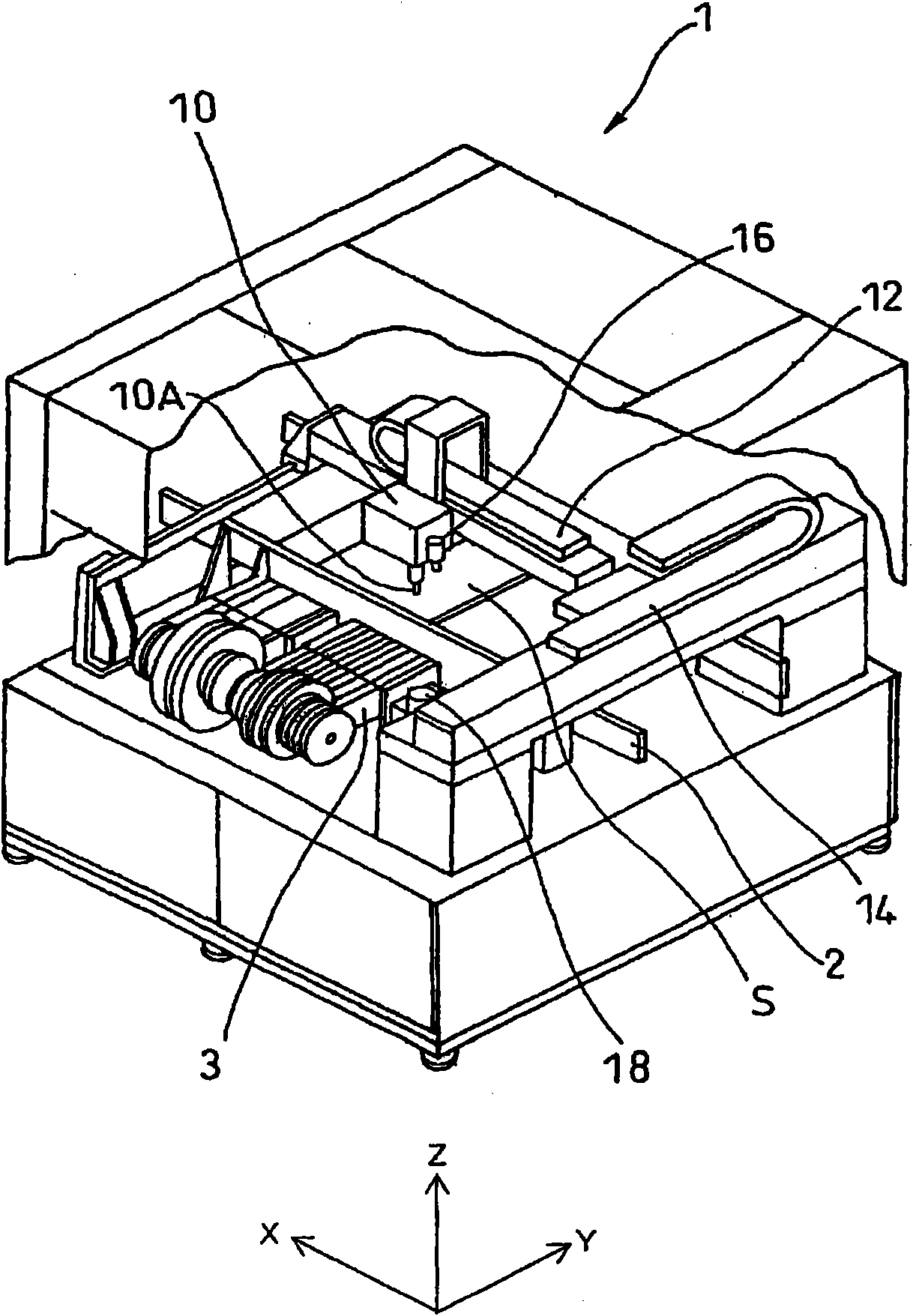

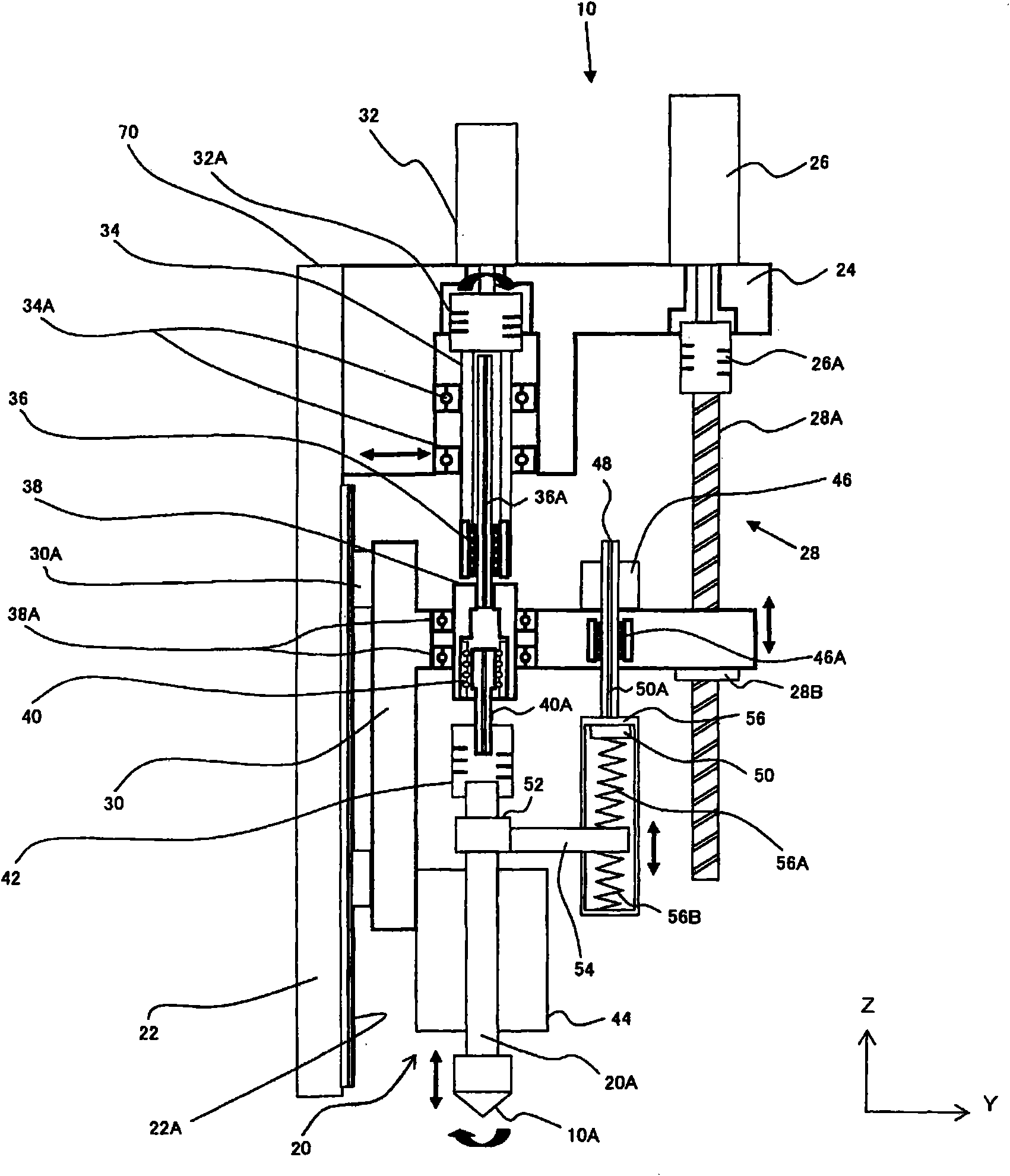

[0024] First, an outline of an electronic component mounting apparatus using the mounting head according to the first embodiment of the present invention will be described.

[0025] Generally, electronic component mounting apparatus 1 such as figure 2 As shown, there are: a mounting head 10, which mounts the electronic components supplied by the component supply unit 3 on the substrate S conveyed and positioned by the substrate conveying path 2 extending in the left-right direction; and an X-axis moving mechanism 12 and a Y-axis moving mechanism. The mechanisms 14 move the mounting head 10 in the X direction and the Y direction, which are perpendicular to each other in the horizontal direction.

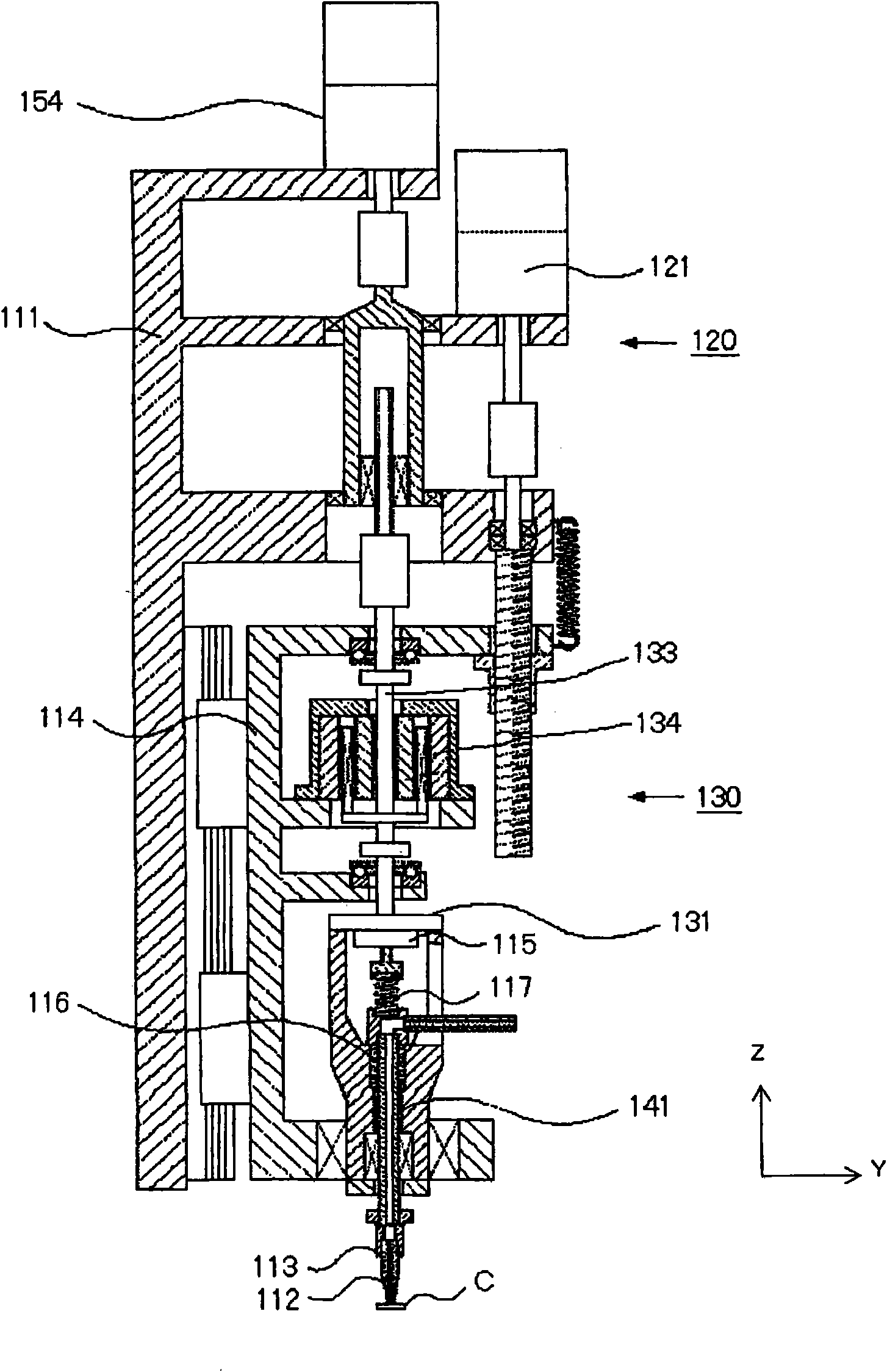

[0026] The X-axis moving mechanism 12 moves the mounting head 10 along the X-axis direction, and the Y-axis moving mechanism 14 moves the mounting head 10 integrally with the X-axis moving mechanism 12 along the Y-axis direction. 1 or 2 or more suction nozzles 10A for parts. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com