Unattended digital multi-well automatic metering device and method

An automatic metering and multi-well technology, applied in the field of metering, can solve problems such as difficult operation and complicated process, and achieve the effect of simple structure, good separation effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

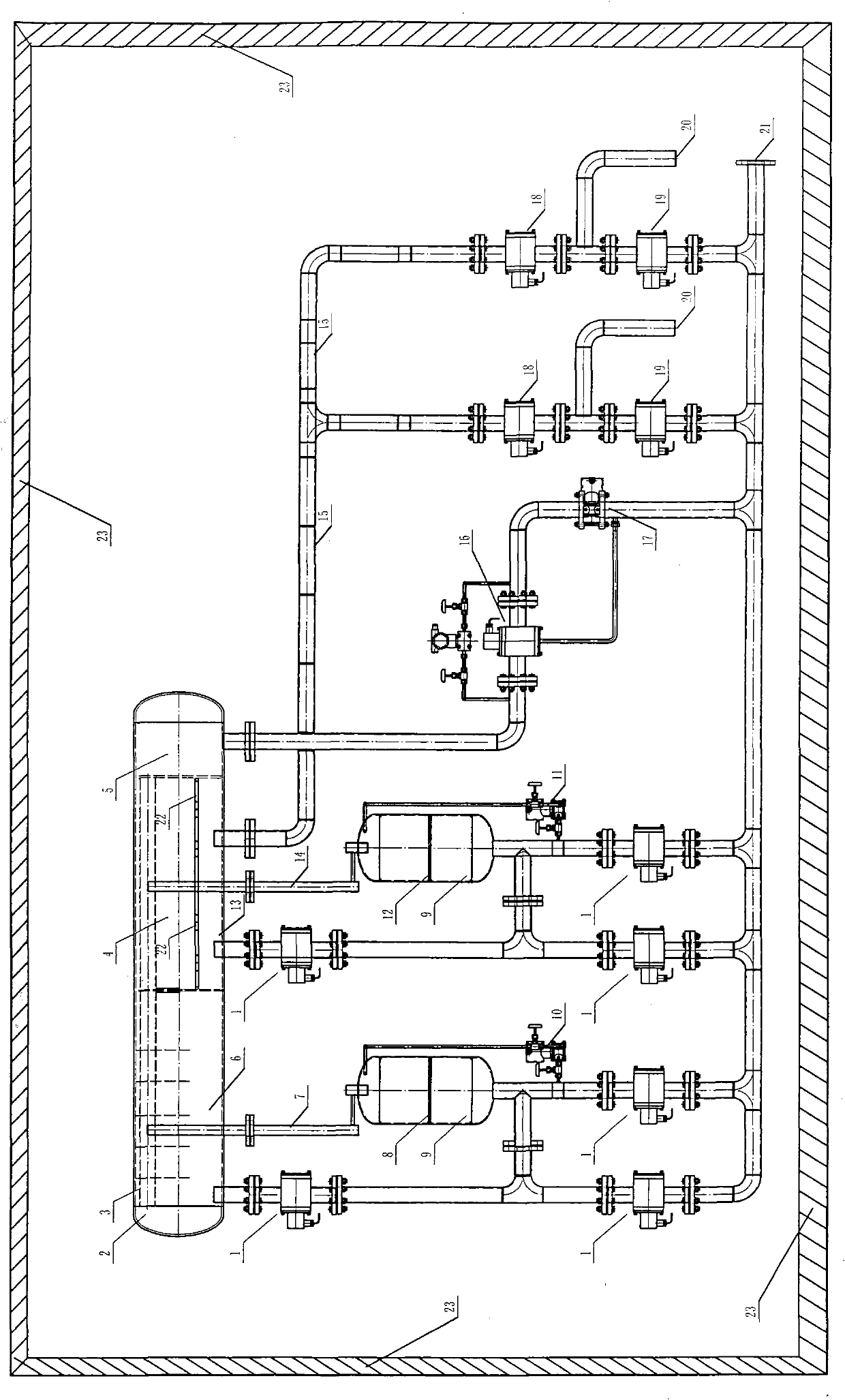

[0007] exist figure 1 Among them, the three-phase piston separator 2 and the manifold valve line are installed in the constant temperature anti-theft metering room 23. One end of the three-phase piston separator 2 is a separation air chamber 5, and the middle is a separation oil chamber 4 and a separation water chamber 13. One end is an oil-gas high-efficiency separation chamber 6, and there is an air guide pipe 3 on the top of the three-phase piston separator 2, and the air guide pipe 3 is connected to the separation air chamber 5; one end of the feed pipe 15 is connected to the discharge pipe, and a manifold is installed in the middle The metering valve 18 at the upper end and the confluence valve 19 at the lower end of the manifold. There is a metering medium inlet 20 between the metering valve 18 at the upper end of the manifold and the confluence valve 19 at the lower end of the manifold. The metering valve 18 at the upper end of the manifold and the confluence valve 19 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com