Hydraulic expansion hanger for expandable screen pipes

A hanger and expansion type technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problem that the hanger cannot meet the requirements for the use of the expansion screen, and achieves the improvement of the success rate of losing hands, high efficiency and two-way Carrying capacity, the effect of eliminating vicious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

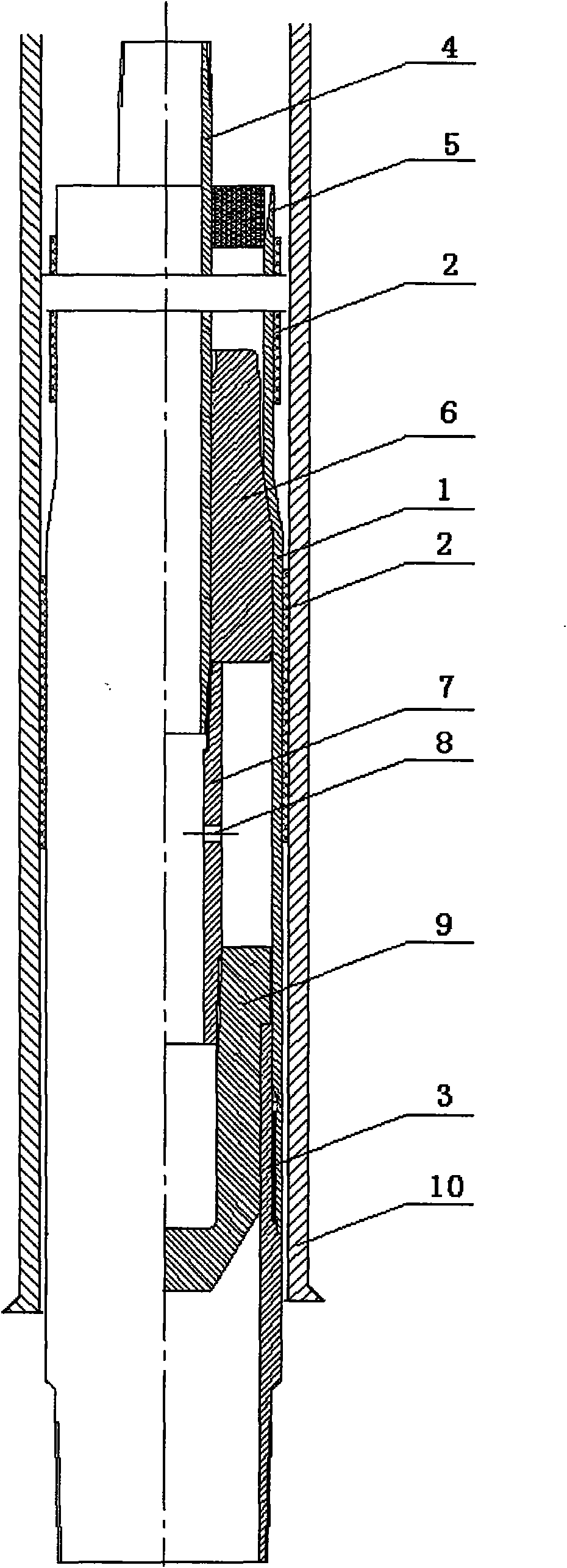

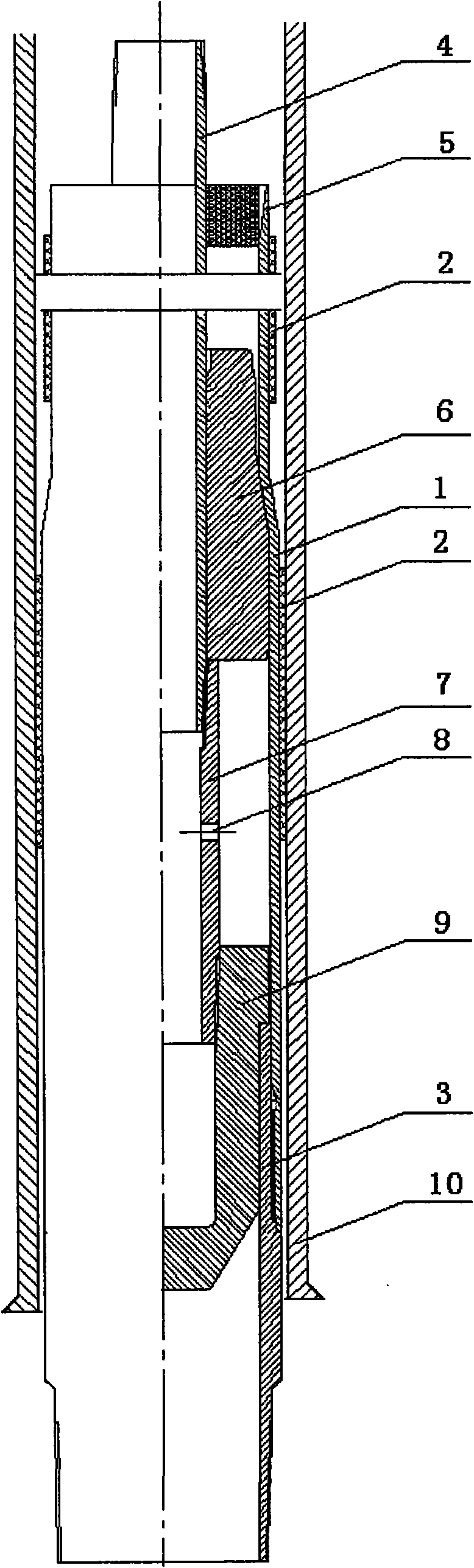

[0020] The present invention will be further described now in conjunction with the accompanying drawings of the description. After the drilling is completed, the bottom of the hydraulic expansion hanger is sealed with variable buckle 3 and connected to the liner string, and the upper part is connected with the central light pipe through the variable buckle with thickened tubing or small drill pipe. , the pressure acts on the expansion cone 6 through the circulating hole 8 on the fixed short joint 7. After the pressure reaches the rated value, the expansion cone 6 moves axially along the central light pipe 4 from bottom to top, so that the suspension body 1 produces a permanent Radial plastic deformation, so that the rubber ring 2 is compressed between the outer wall of the hanger body 1 and the inner wall of the outer casing 10, and plays the dual role of hanging the tail pipe and sealing. After the expansion cone 6 expands out of the hanger body 1, the wellhead automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com