Road-passing railcar

A rail car and track technology, applied in the field of rail cars through the road, can solve the problems that the lifting platform cannot be vertical to horizontal, is not easy to automate, and delays time, so as to achieve the effect of convenient space layout, saving time and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

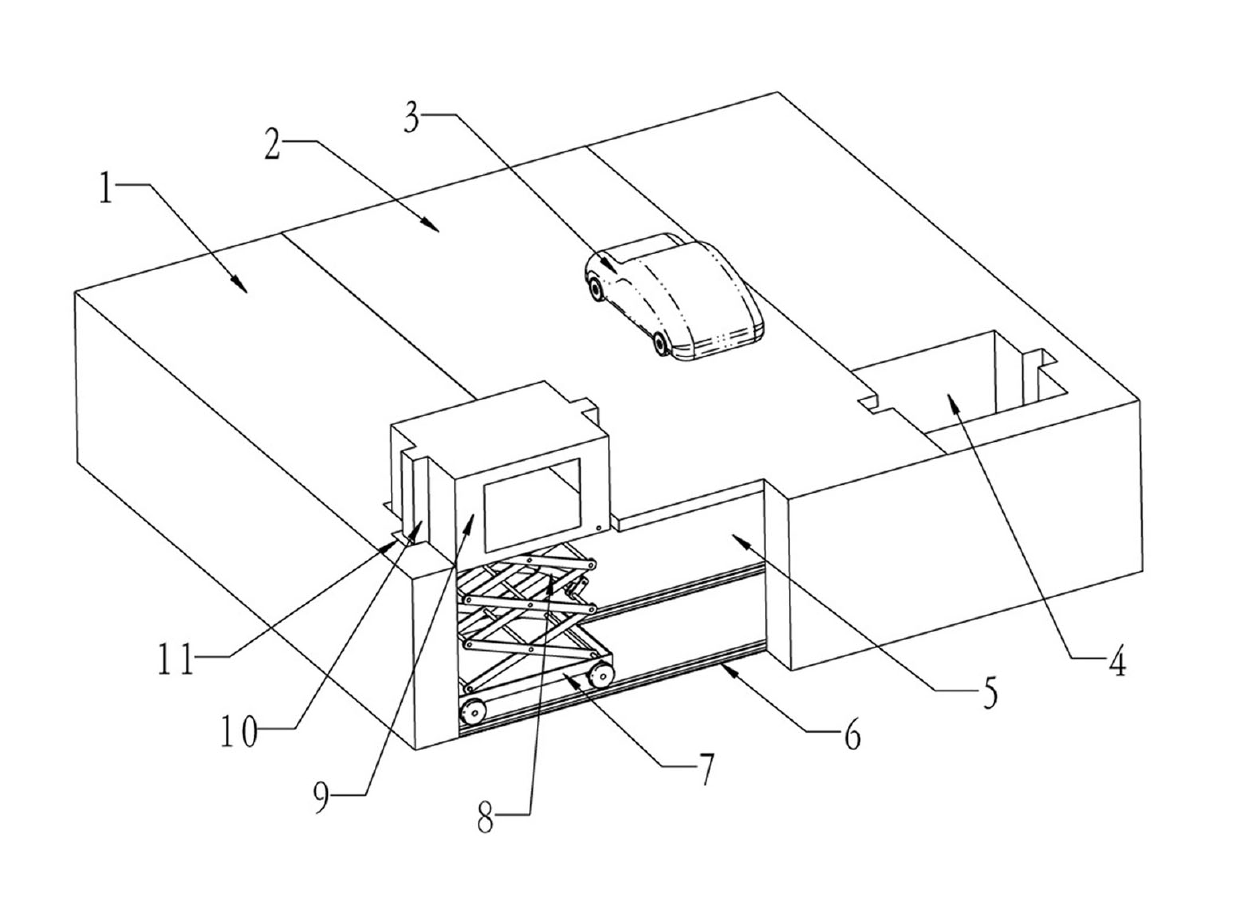

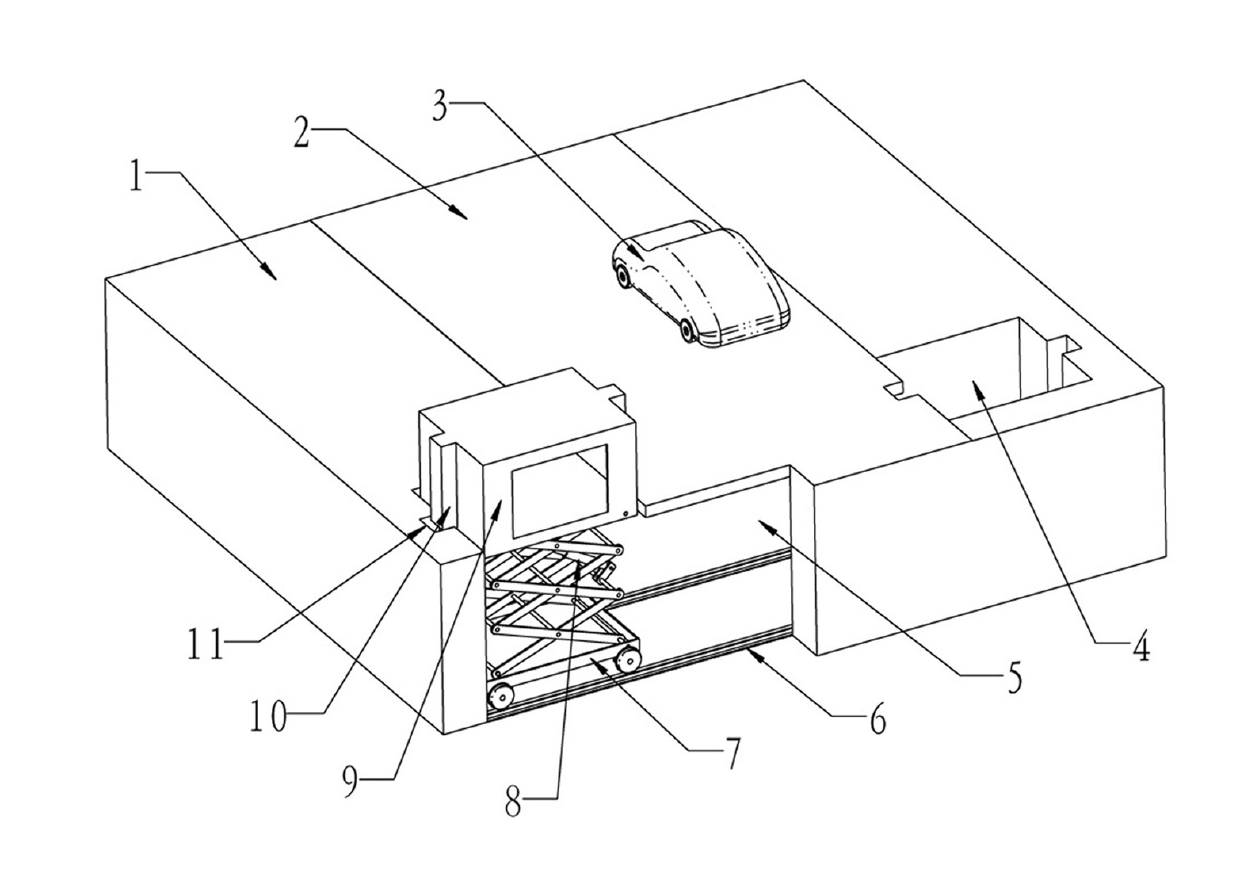

[0009] detailed description: figure 1 It is the working sketch map of the present invention crossing track car, in order to better explain the working principle, to figure 1 The section of the road in . In the figure, there are sidewalks (1), driveways (2), and motor vehicles (3). Be provided with vertical channel (4) on the sidewalk (1) side left and right, the following of lane (2) is horizontal channel (5), and the bottom of horizontal channel (5) is paved with track (6), and there is car on track (6) body (7), there is a lifting mechanism (8) on the car body (7), the lifting mechanism (8) in this example is a hydraulic lifting platform, and the lifting mechanism (8) has lifted the compartment (9) to the sidewalk in the figure The height of (1), the guide block (10) and the guide groove (11) between the carriage (9) and the vertical passage (4) are to ensure that the carriage (9) can be lifted and lowered more accurately in the vertical passage (4) . There are two doors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com