Flow channel tube assembling device

A technology of runners and channels, which is applied in the field of paper tube assembly devices, can solve the problems of low stability in use, high cost of man-hours, and low quality, and achieve the effects of neat and regular shapes, good overall structural strength, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

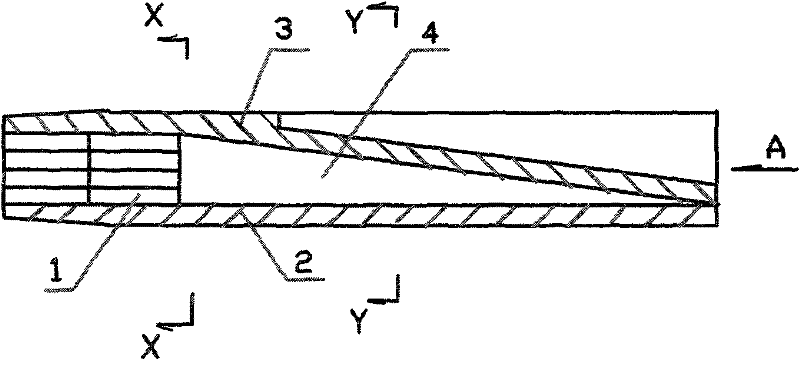

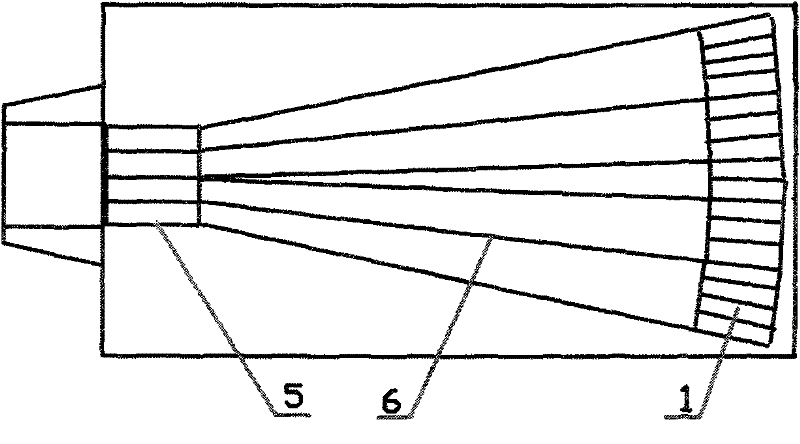

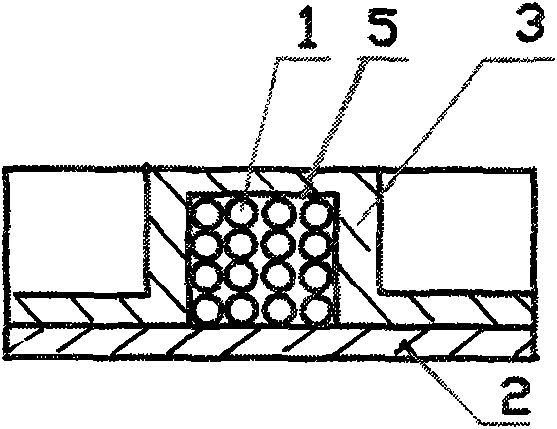

[0014] Example 1, in Figure 1 to Figure 5 Among them, the flow channel assembly device includes two molded bodies (namely upper molded body 3 and lower molded body 2) that can be opened and closed each other, two left ends between upper molded body 3 and lower molded body 2 Each end has a storage cylinder cavity 5 with an opening. The cross section of the storage cylinder cavity is square. The horizontal direction of the block is a strip-shaped bump 6. The cross-section of the bump is triangular, and the tip and the bump are transitioned with rounded corners. The horizontal direction of the bump is inclined, and the right end of the bump (lower) Located on the joint surface of the lower mold body, the left end (high point) of the bump is connected to the top surface of the opening of the storage chamber, the right ends of the two protrusions are arranged at intervals, and the left ends of the two protrusions are closely connected to the side of the storage chamber after they ...

Embodiment 2

[0015] Embodiment 2, can refer to Figure 1 to Figure 5 The difference between the present embodiment 2 and the embodiment 1 is that only one bump 6 is set on the lower mold body 2, and a groove 7 corresponding to the shape and position of a bump is set in the upper mold body. An inverted V-shaped channel 4 is formed between the groove and the groove, and a rectangular storage chamber 5 is provided at the left end between the upper mold body 3 and the lower mold body 2. In addition, the present embodiment 2 and the implementation Example 1 has the same structure. In this embodiment 2, there are 8 paper tubes in rows, and four paper tubes 1 are placed on the side of the protrusion to form a 2×4 arrangement. Glue is sprayed on the paper tubes, and then the paper tubes are moved along the The channel moves synchronously, so that the paper tube is folded horizontally in the channel and squeezed and pushed into the cavity of the storage tube to form a rectangular combined paper tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com