Ultra-clean low-carbon low-silicon steel wire rod controlled rolling process

A low-carbon, low-silicon, steel wire rod technology, applied in temperature control, metal rolling, rolling force/roll gap control, etc., can solve problems such as small denaturation resistance, high deformation rate, and large deformation of rolled pieces, and achieve Improve the accuracy of specification control, improve the accuracy of specification size, and avoid the effect of overfilling the hole pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. First, put the billet into the heating furnace for heating, and the temperature in the soaking section is controlled at 950-970°C.

[0027] 2. Tapping for rolling, the actual rolling temperature is 880-900°C.

[0028] 3. Increase the roll gap of the last two rolls of the pre-finishing rolling by 0.1mm, that is, the 16th pass is adjusted to 3.5mm, and the 17th pass is adjusted to 2.4mm.

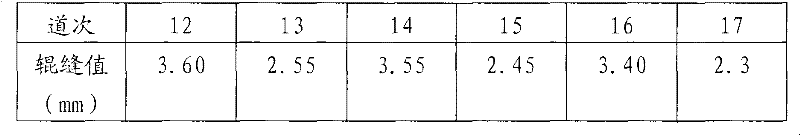

[0029] 4. Increase the roll gap of the last 4 rolls of the finishing mill by 0.15mm. The adjusted roll gap is shown in Table 3.

[0030] 5. After rolling, the rolling process is completed through silk spinning, coil collection, and storage.

[0031] Table 3 Roll Gap Schedule of Finishing Mill

[0032]

[0033]

Embodiment 2

[0035] 1. First, put the billet into the heating furnace for heating, and the temperature in the soaking section is controlled at 960-980°C.

[0036] 2. Tapping for rolling, the actual rolling temperature is 890-910°C.

[0037] 3, with embodiment 1.

[0038] 4, with embodiment 1.

[0039] 5. After rolling, the rolling process is completed through silk spinning, coil collection, and storage.

Embodiment 3

[0041] 1. First put the steel billet into the heating furnace for heating, and the temperature in the soaking section is controlled at 980-1000°C.

[0042] 2. Tapping for rolling, the actual rolling temperature is 910-930°C.

[0043] 3, with embodiment 1.

[0044] 4, with embodiment 1.

[0045] 5. Complete the rolling process after silk spinning, coil collection and storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com