Plastic liquor container for a washing machine or a clothes dryer, and method for the production of a liquor container

A technology for cleaning plastics and washing machines, applied in other washing machines, applications, washing devices, etc., can solve problems such as limitations, and achieve the effects of easy control, cost reduction, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

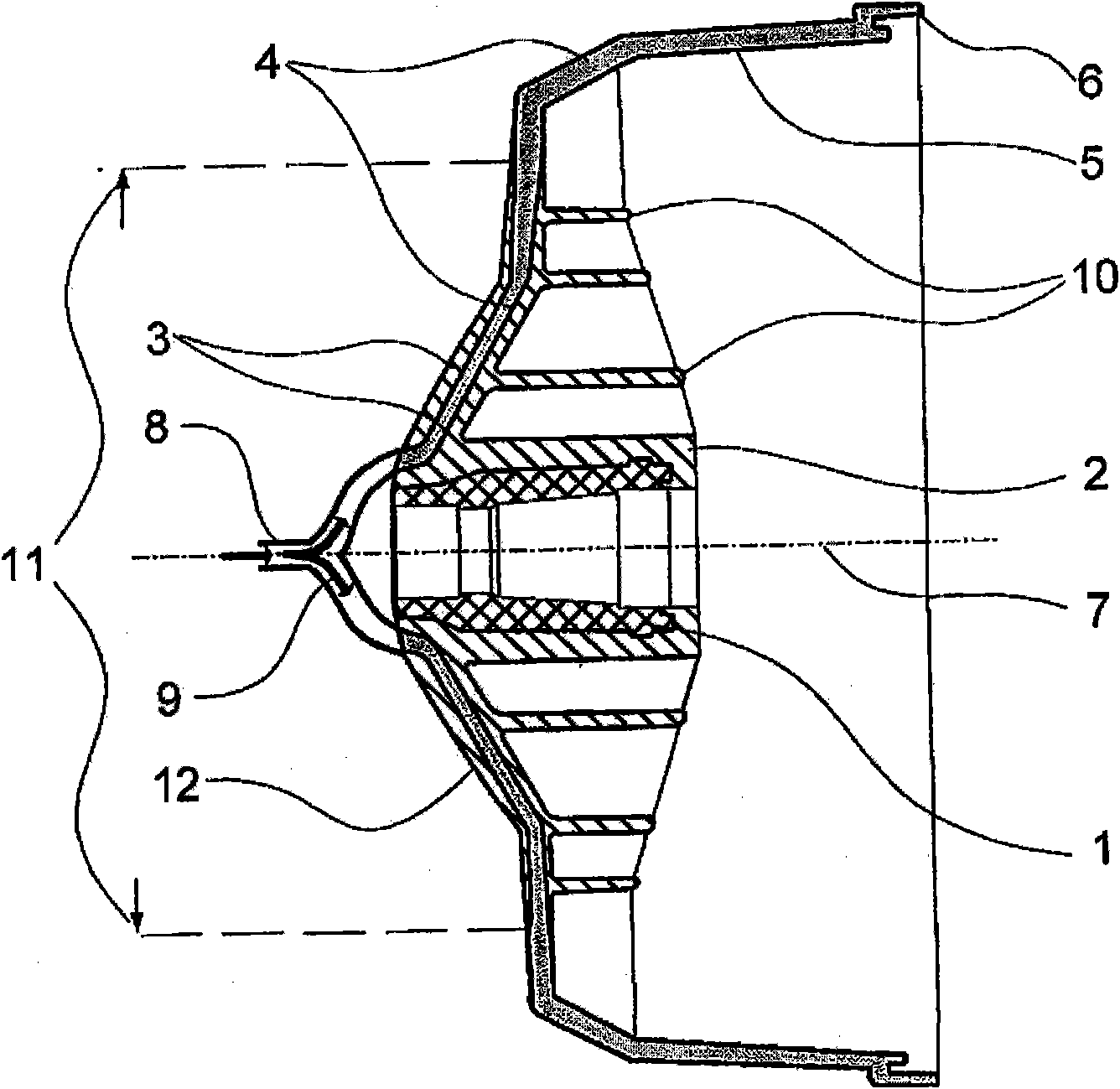

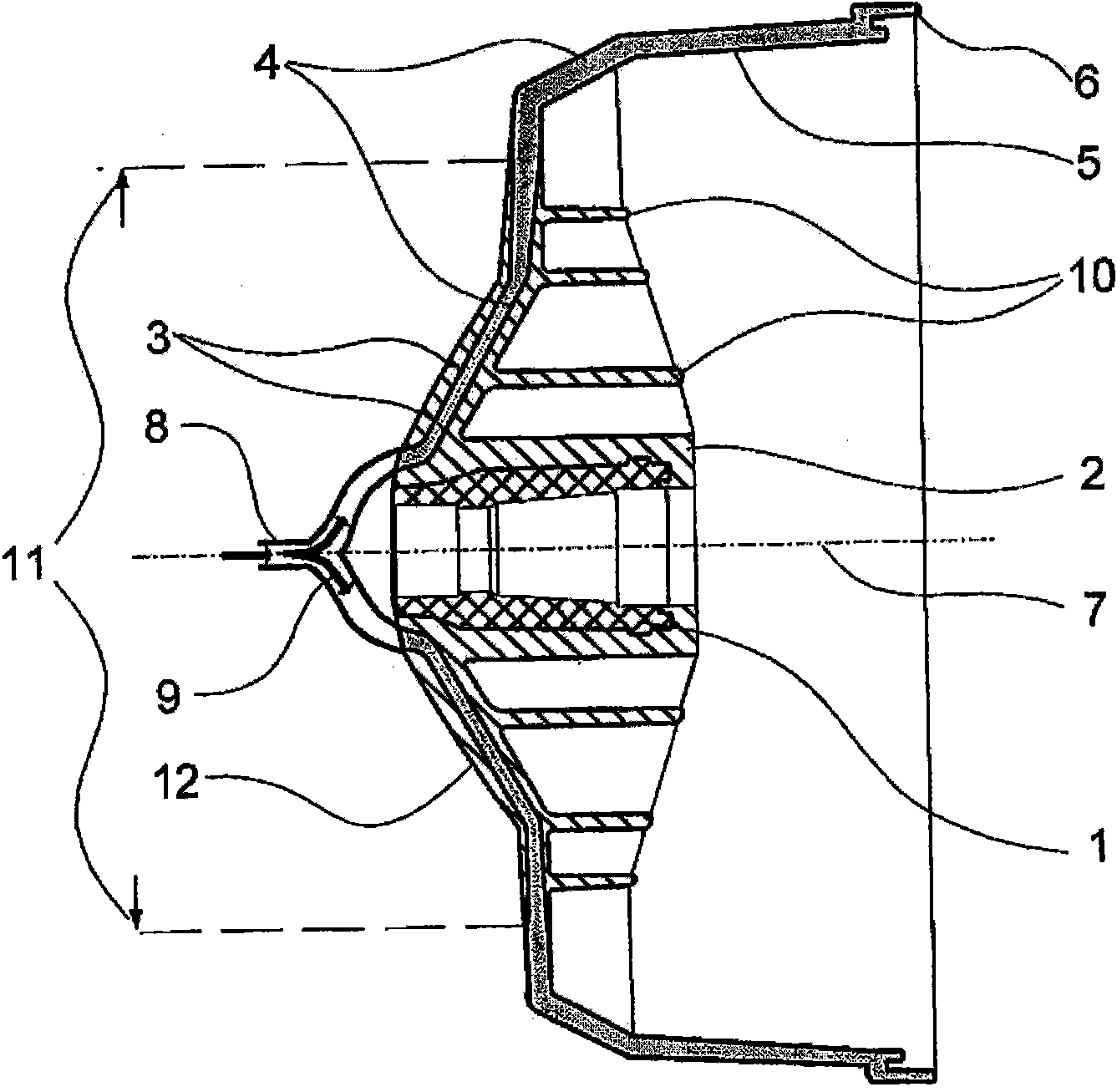

[0022] The drawing shows a sectional view perpendicular to the drum axis 7 of an embodiment of the rear wall of the washing container according to the invention which is produced in one piece by injection molding.

[0023] The cleaning container rear wall comprises the rear end side wall of the cleaning container, which has a bearing receptacle for the roller shaft; the transition area 5 of the cylindrical cleaning container cover and the receptacle 6 for connecting and screwing the cleaning container cover; and Circularly symmetrical molded reinforcing ribs 10 . For the sake of simplification of the drawing, the radial and meandering reinforcing ribs also provided are not shown.

[0024] As shown, the thickness of the rear wall 12 and the height of the ribs decrease from the carrying receptacle 2 to the container sleeve 5 . The inventive rear wall region of the sandwich structure 11 is circular in this exemplary embodiment and arranged symmetrically with respect to the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com