Foamed aluminum energy-storage type electric heating boiler

An electric heating boiler and foam aluminum technology, which is applied to central heating, can solve the problems affecting the safe operation of the power supply grid, the electric heating boiler consumes a lot of electricity, and the heating cost is high, so as to prolong the water temperature retention time, improve the heat storage capacity, and reduce the heating cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

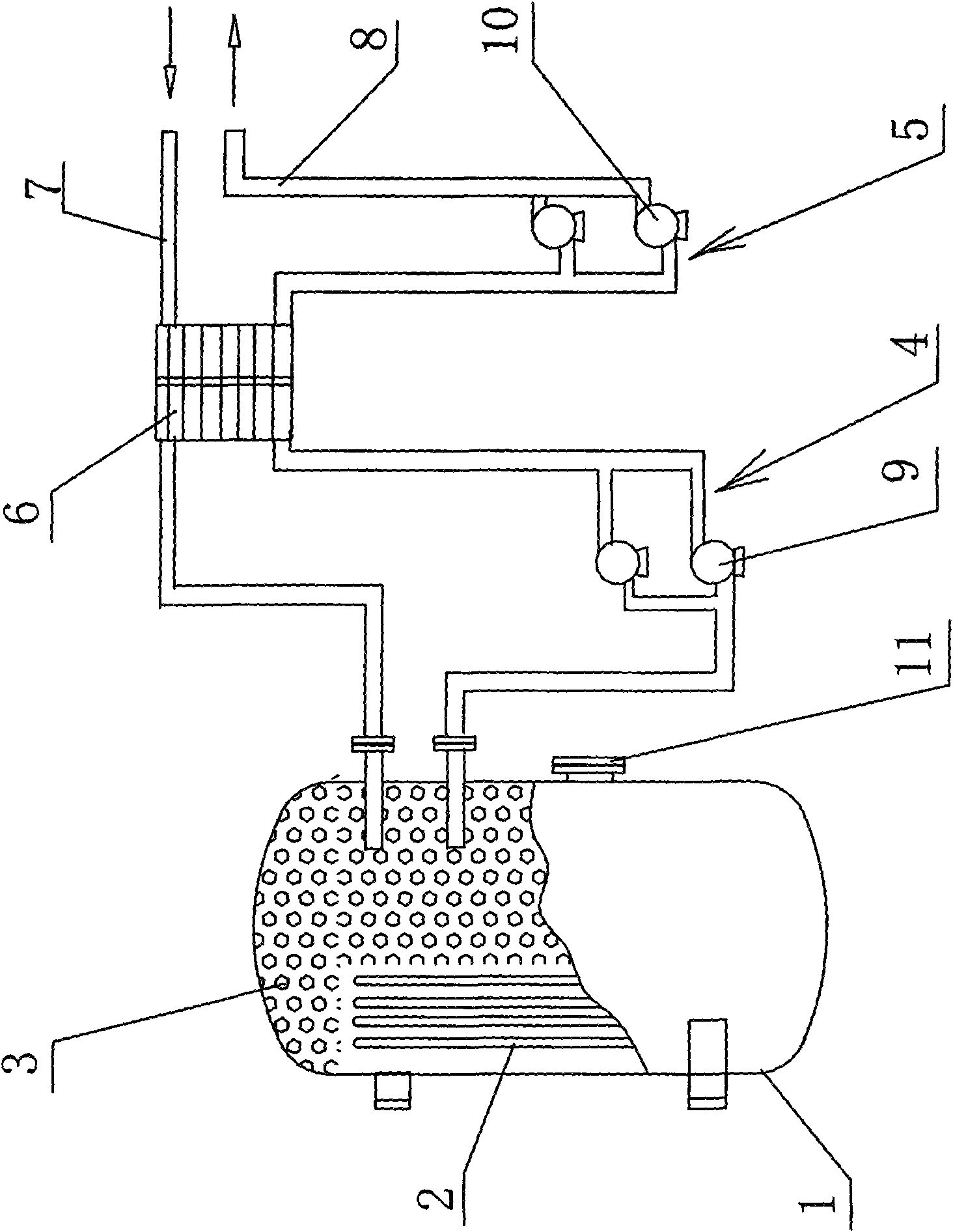

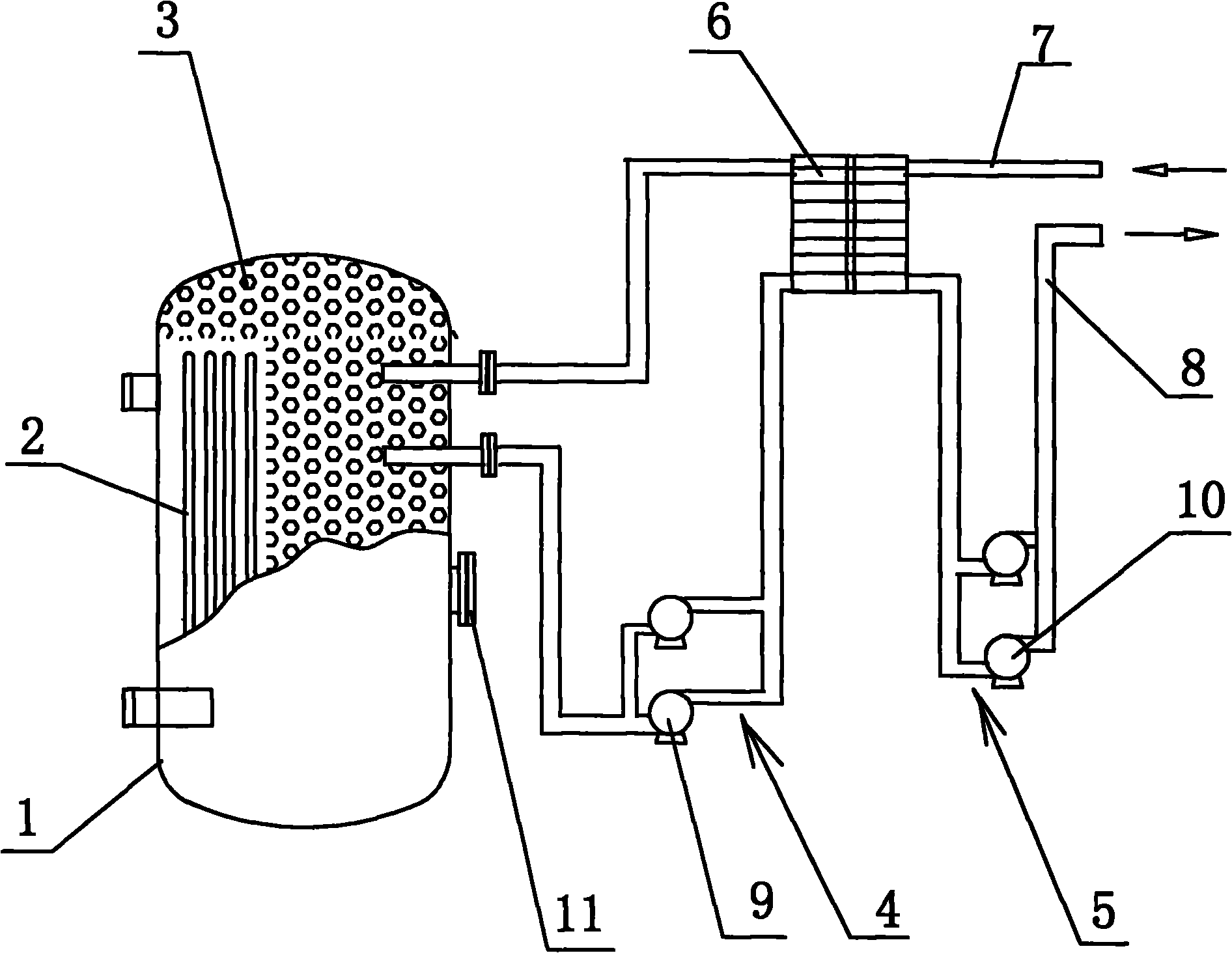

[0011] The aluminum foam energy storage type electric heating boiler includes a furnace body 1, an electric heating element tube 2, an aluminum foam 3, an internal circulation pipe network 4, an external circulation pipe network 5 and a heat exchanger 6. Furnace body 1 is provided with water inlet pipe 7 and water outlet pipe 8, and water inlet pipe 7 and water outlet pipe 8 are respectively connected to the upper and lower ends of heat exchanger 6. Energy storage medium aluminum foam. The inner circulation pipe network 4 and the outer circulation pipe network 5 are connected to the water outlet pipe 8, and the inner circulation pipe network is controlled by the circulating water pump 9 on the inner circulation pipe network 4 to improve the heat storage of the energy storage medium aluminum foam 3 in the furnace body; through the outer circulation pipe network The circulating water pump 10 is controlled to provide a heat source to the outside. The furnace body 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com