Automatic centering clamping feeding and discharging device

An automatic centering, feeding and discharging technology, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of affecting output, low rhythm efficiency, etc., and achieve the effects of convenient operation, simple structure and flexible action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

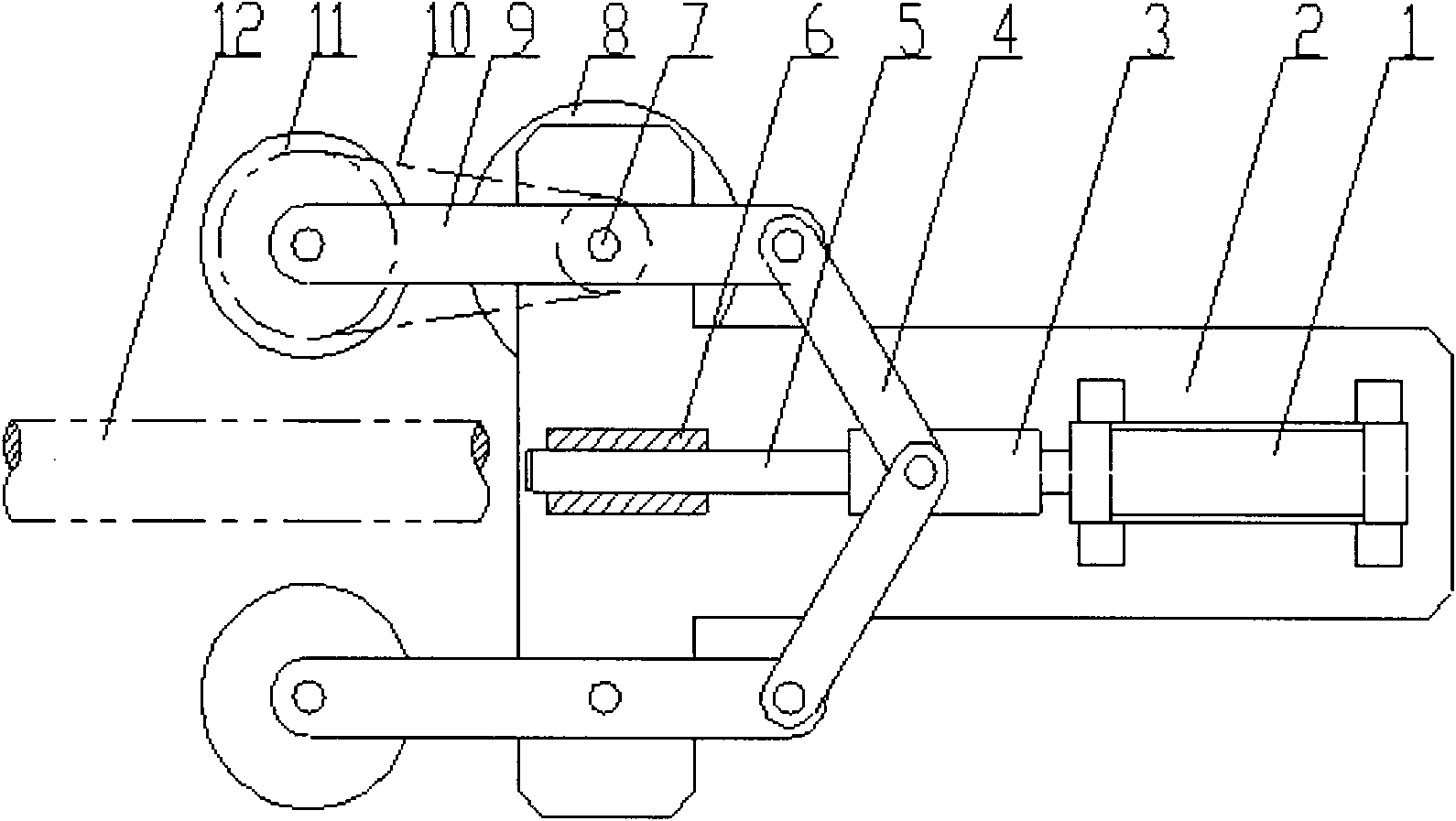

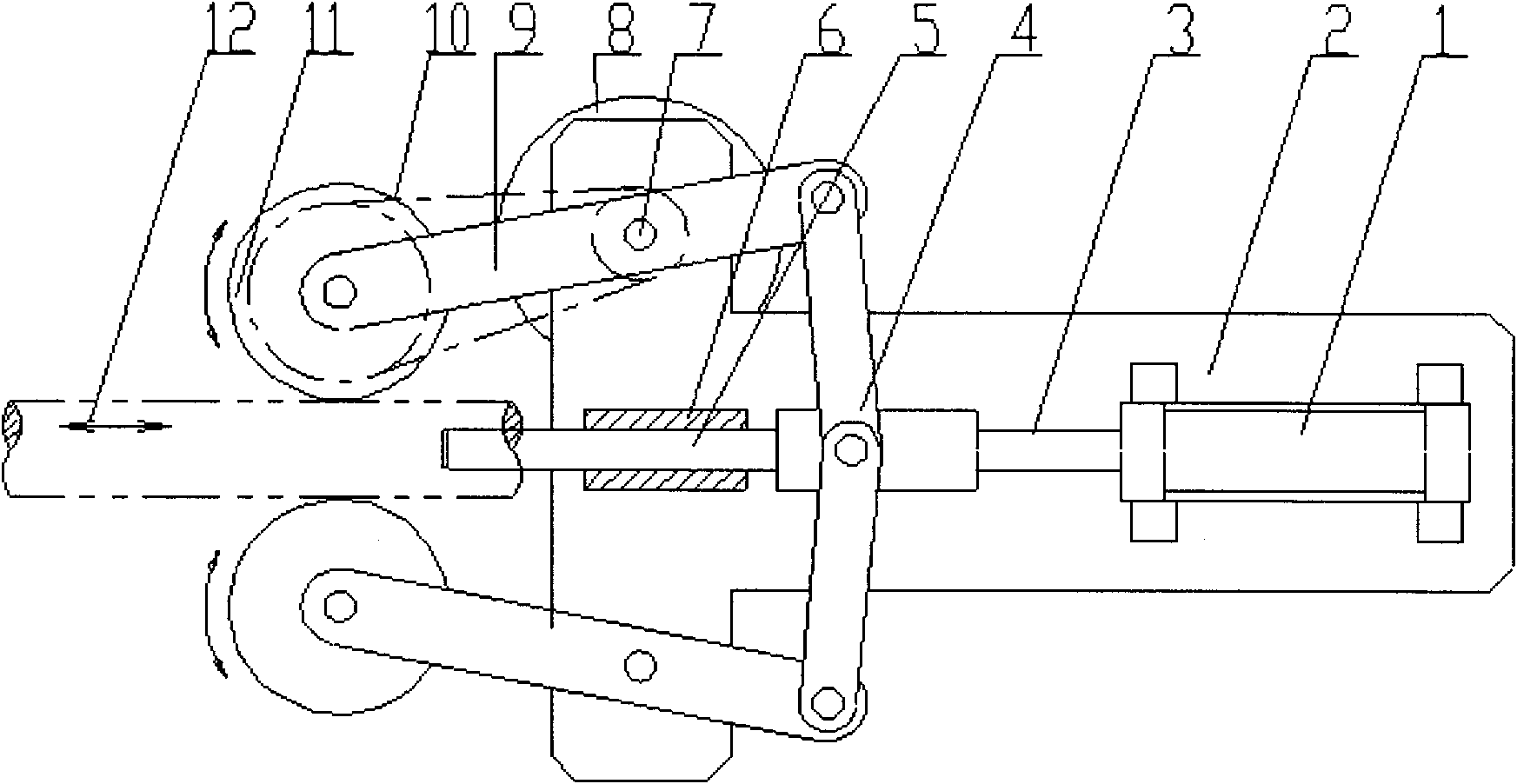

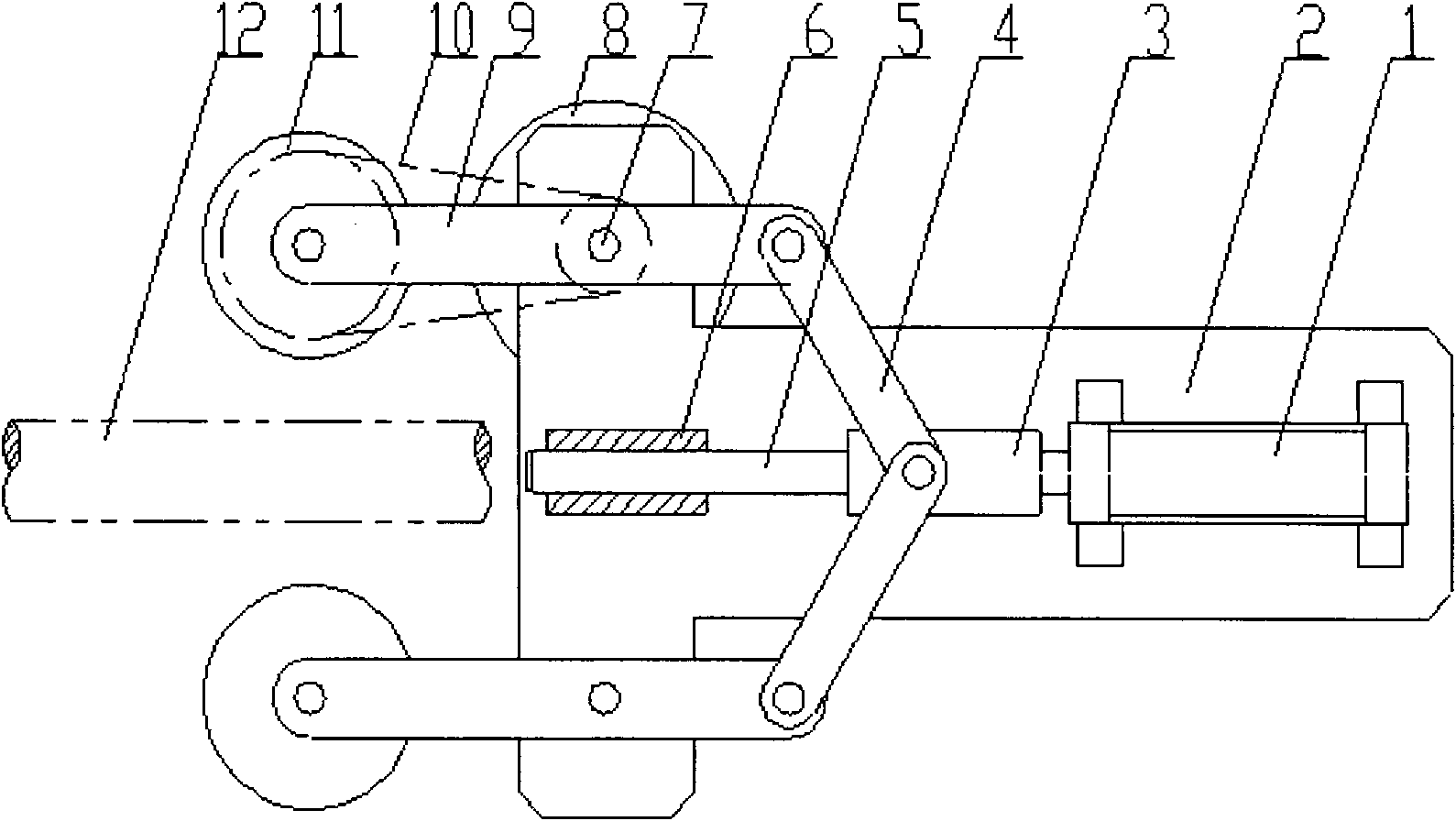

[0008] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are described in detail

[0009] Referring to the accompanying drawings, an automatic centering and clamping feeding and discharging device includes a base 2, and one end of the base 2 is provided with a cylinder 1, and the cylinder joint 3 on the cylinder 1 is movably connected with two connecting rods 4 through a pin shaft, and the cylinder joint 3 The topmost end is connected with a guide rod 5, the guide rod 5 passes through the guide sleeve 6 fixed on the base, the two connecting rods 4 are connected with the two rocker arms 9 through the pin shaft, and the rocker arm 9 is fixed on the base through the pin shaft 7 and can rotate around the pin shaft 7. A pinch roller 11 is installed at the end of the rocker arm 9. The opening and closing of the pinch roller 11 is realized by the rotation of the rocker arm 9. A motor 8 and a motor 8 are also installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com