Method for manufacturing total auditory ossicle prosthesis

A prosthesis and standard technology, applied in the field of artificial organs, can solve the problems of increasing the burden of surgery, low operating costs for doctors, and high prices, and achieve the effects of saving surgery costs, avoiding prosthesis waste, and making it easy to make.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] First, the production of model prosthesis,

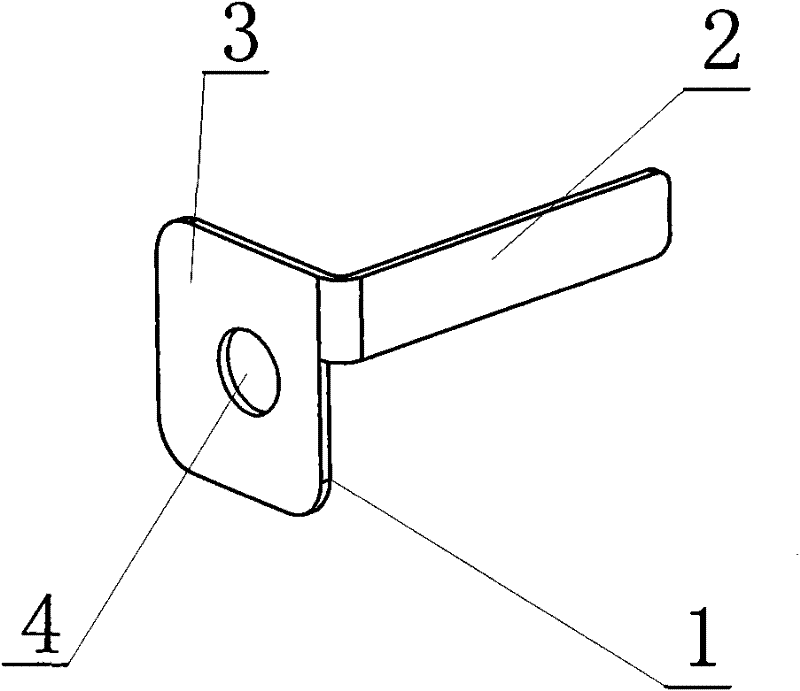

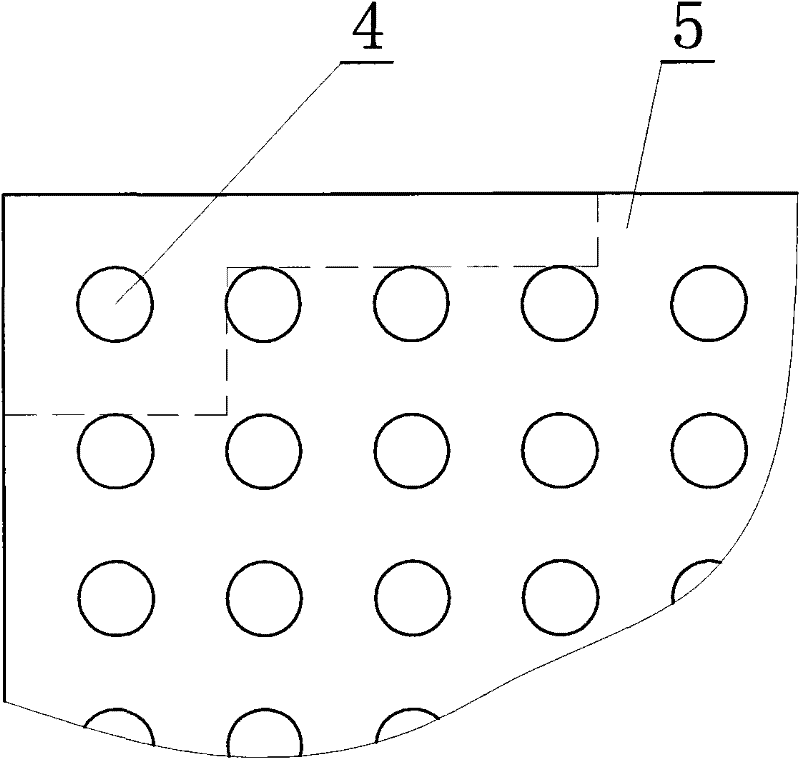

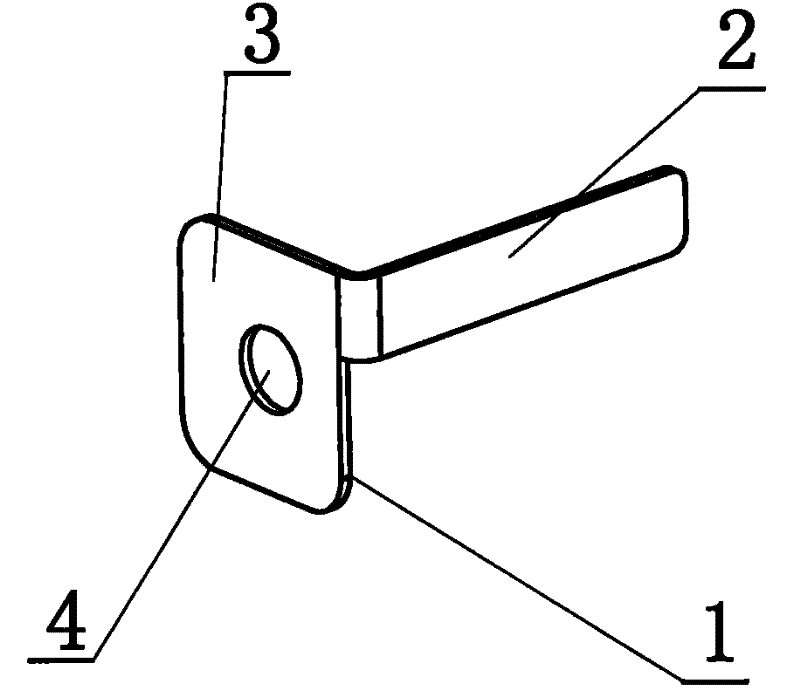

[0013] See attached figure 2 , the model prosthesis 1 adopts the titanium mesh 5 made of medical titanium material specified in GB T 13810-1997 "Titanium and Titanium Alloy Processing Materials for Surgical Implants", the thickness of the titanium mesh 5 is 0.2mm, and the diameter of the garden hole 4 is 1.5 mm. mm, the mesh spacing is 1.5mm, along with figure 2 Cut off the strip with 4 mesh lengths in the dotted line as the strip handle 2, and leave 1 mesh at one end as the mesh end 3 to form a square of 3.5x3.5mm at the mesh end 3, and the strip handle 2 It is a strip of 1.5x7mm, use a steel file to flatten the edges and corners around it, and then bend the strip handle 2 so that the strip handle 2 and the mesh end 3 form an "L"-shaped right angle model prosthesis 1, model prosthesis 1 It can also be processed by stamping dies.

[0014] 2. Placement of the model prosthesis

[0015] The above-mentioned model prosthesis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com