Spiral film element, spiral film-filtration device having the film element, and film-filtration device managing system and film-filtration device managing method using the device

A technology of spiral type and membrane elements, which is applied in the direction of cooperative devices, chemical instruments and methods, engine components, etc., can solve the problems of shortening the life of each membrane element, failing to perform maintenance well, and failing to obtain good results, etc., to achieve The effect of high-precision management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

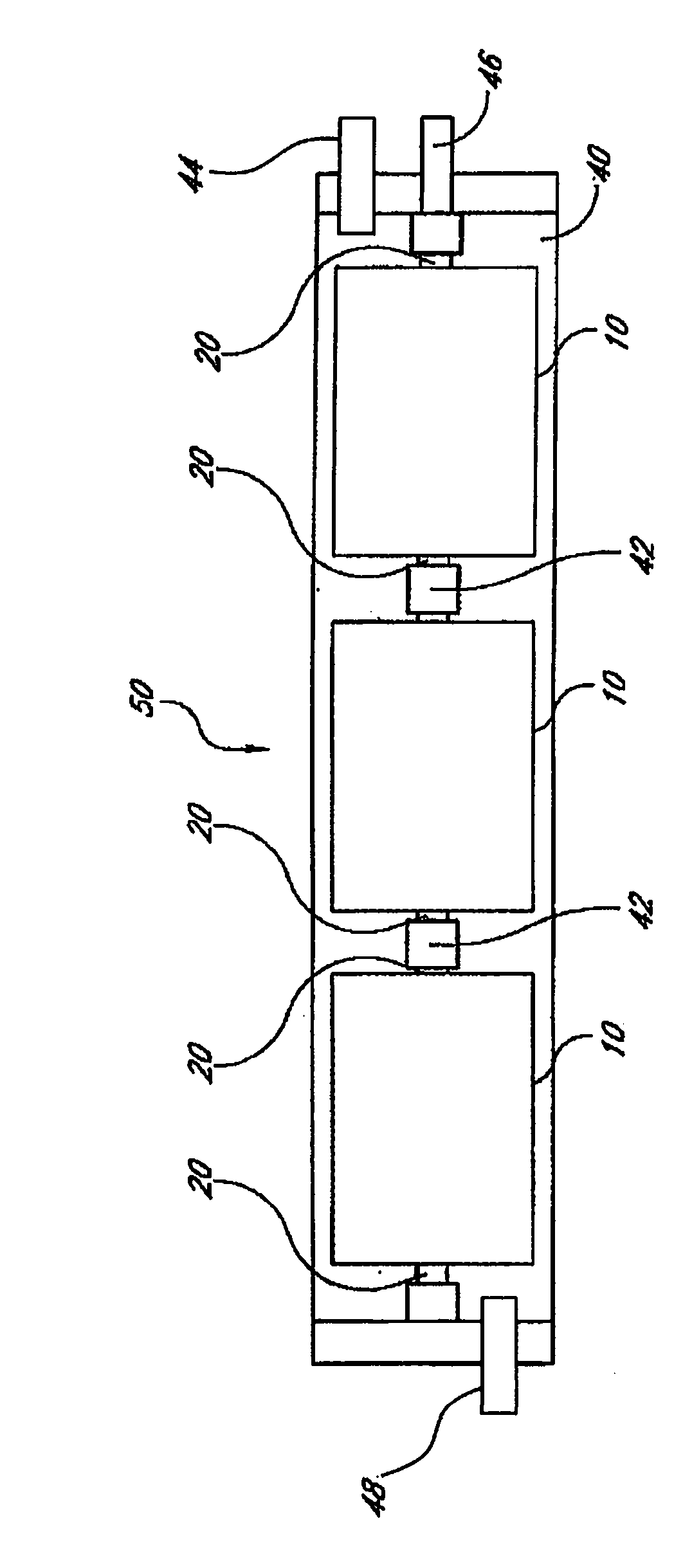

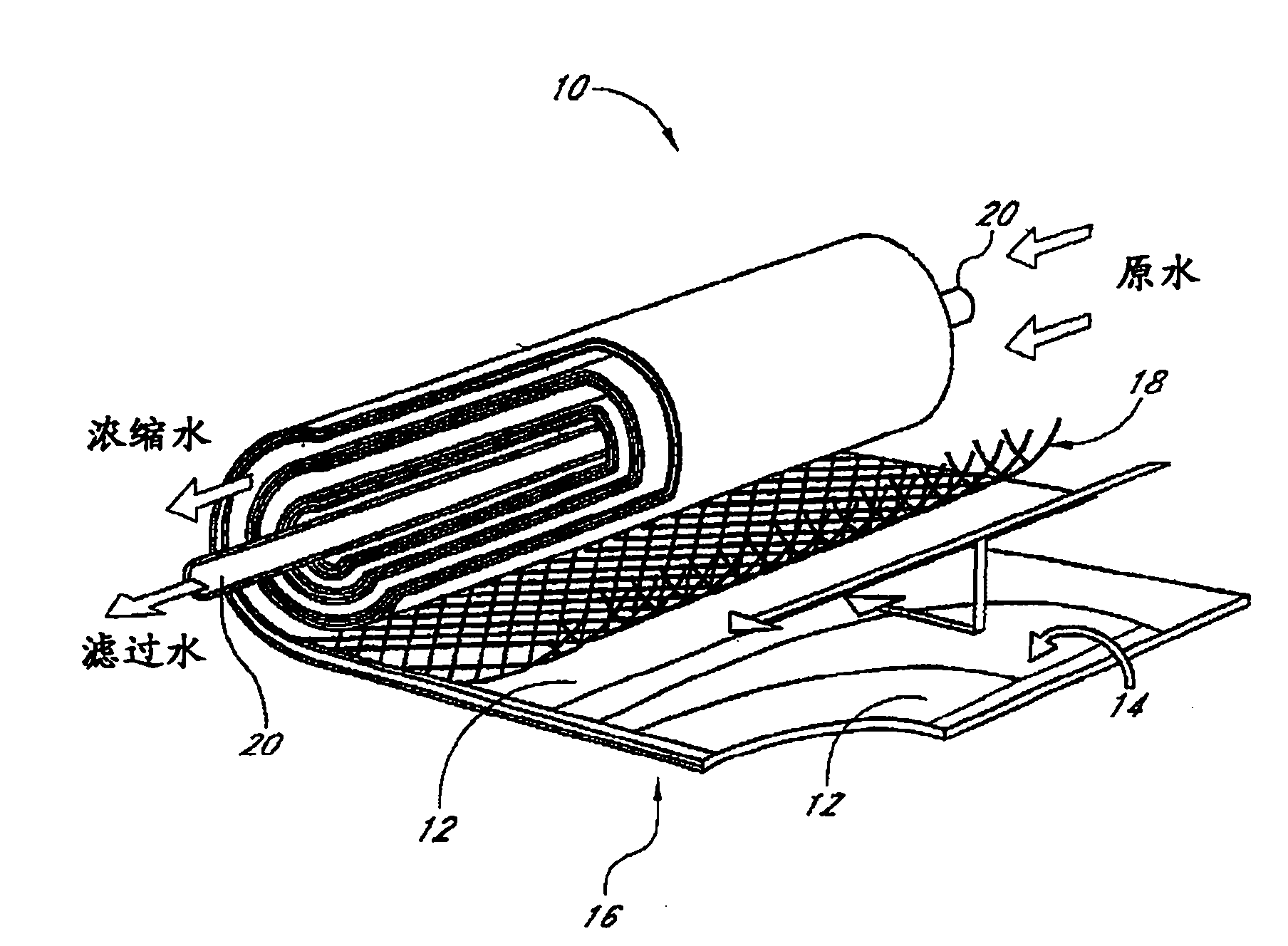

[0045] figure 1 It is a schematic cross-sectional view showing an example of a spiral membrane filtration device 50 including the spiral membrane element 10 according to the first embodiment of the present invention. also, figure 2 yes means figure 1 A perspective view of the internal structure of the spiral membrane element 10. This spiral membrane filtration device 50 (hereinafter simply referred to as “membrane filtration device 50 ”) is configured by arranging a plurality of spiral membrane elements (hereinafter simply referred to as “membrane elements 10 ”) on a straight line in the outer cylinder 40 .

[0046] The outer cylinder 40 is a resin cylinder called a pressure vessel, and is formed of, for example, FRP (Fiberglass Reinforced Plastics). One end of the outer cylinder 40 is formed with a raw water inlet 48 through which raw water (stock solution) such as drainage and sea water flows in, and the raw water flowing in from the raw water inlet 48 is filtered by a p...

no. 2 approach

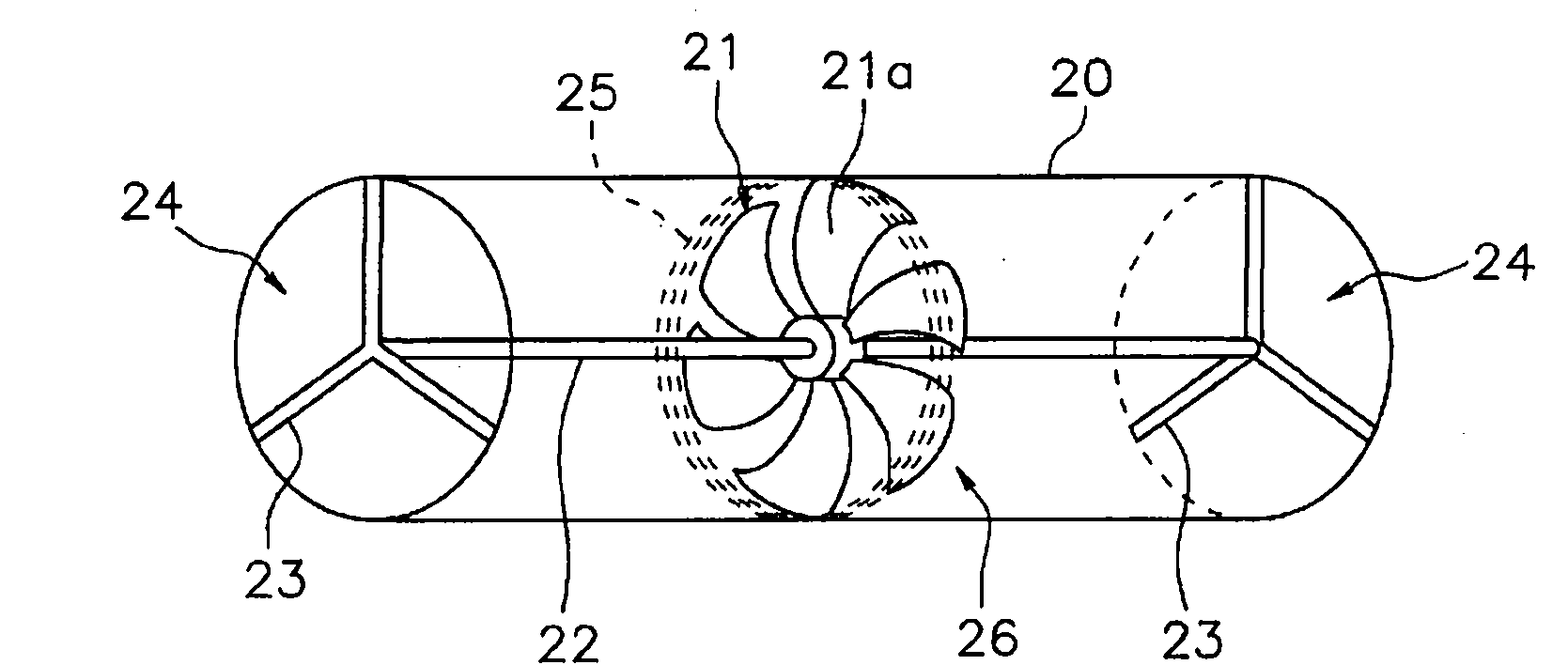

[0066] In the first embodiment, a configuration in which power generation is performed based on the rotation of the rotating body (impeller 21 ) provided in the center pipe 20 has been described. In contrast, the second embodiment is different in that a rotating body is provided in the raw water flow path formed by the supply-side flow path member 18 .

[0067] Figure 5 It is a schematic perspective view showing an example of the internal structure of the spiral membrane element 10 according to the second embodiment of the present invention, and shows a state in which the internal structure is seen through. In this example, the membrane member 16 wound around the central tube 20 is divided into two along the axial direction of the central tube 20 , and a space 27 is formed between the end surfaces of the divided membrane members 16 . This space 27 is a region where raw water flows from the raw water flow path 28 formed by the supply-side flow path member 18 in one of the div...

no. 3 approach

[0073] In the second embodiment, a structure in which power generation is performed based on the rotation of a rotating body (impeller 121 ) provided at the center of the membrane element 10 has been described. On the contrary, the third embodiment is different in that a rotating body is provided at the end of the membrane element 10 .

[0074] Figure 6 It is a schematic perspective view showing an example of the internal structure of the spiral membrane element 10 according to the third embodiment of the present invention, and shows a state in which the internal structure is seen through. In this example, a seal carrier for holding a seal member (not shown) on the outer peripheral surface of the membrane element 16 wound around the central tube 20 in the axial direction, or a device for preventing the expansion and contraction deformation of the membrane member 16 is attached. The anti-telescopic part functions as the end part 11 . The raw water flowing in the raw water ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com