Method for improving mother solution salinity and reducing pure alkali loss

A salt and mother liquor technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of large loss and soda ash cannot be recycled, and achieve the effect of increasing energy consumption, reducing soda ash loss, and reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

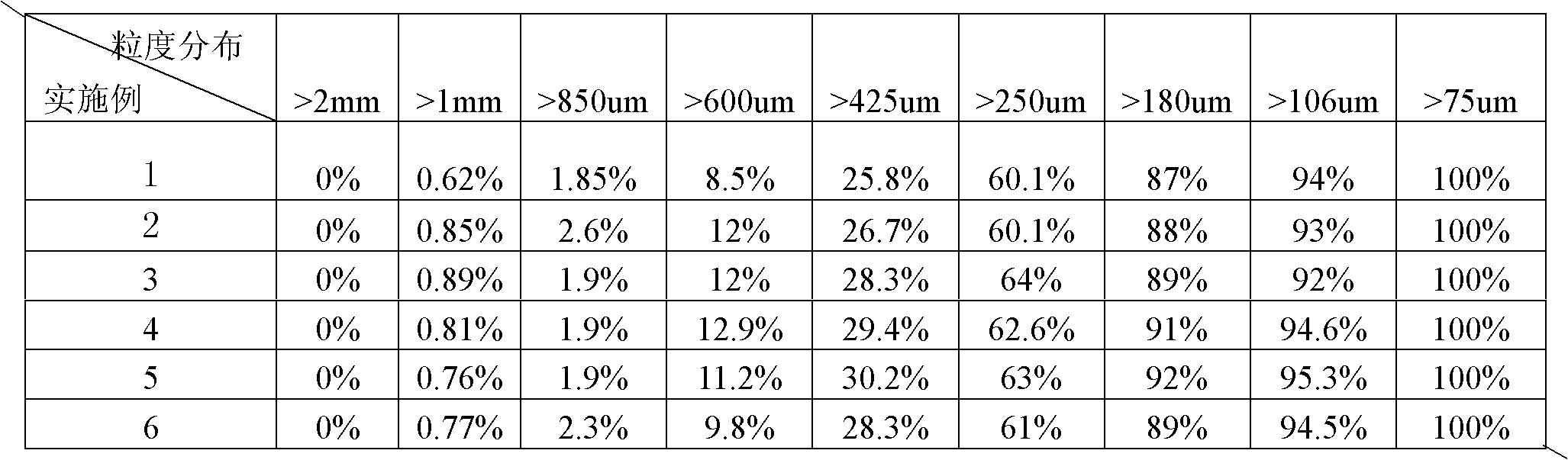

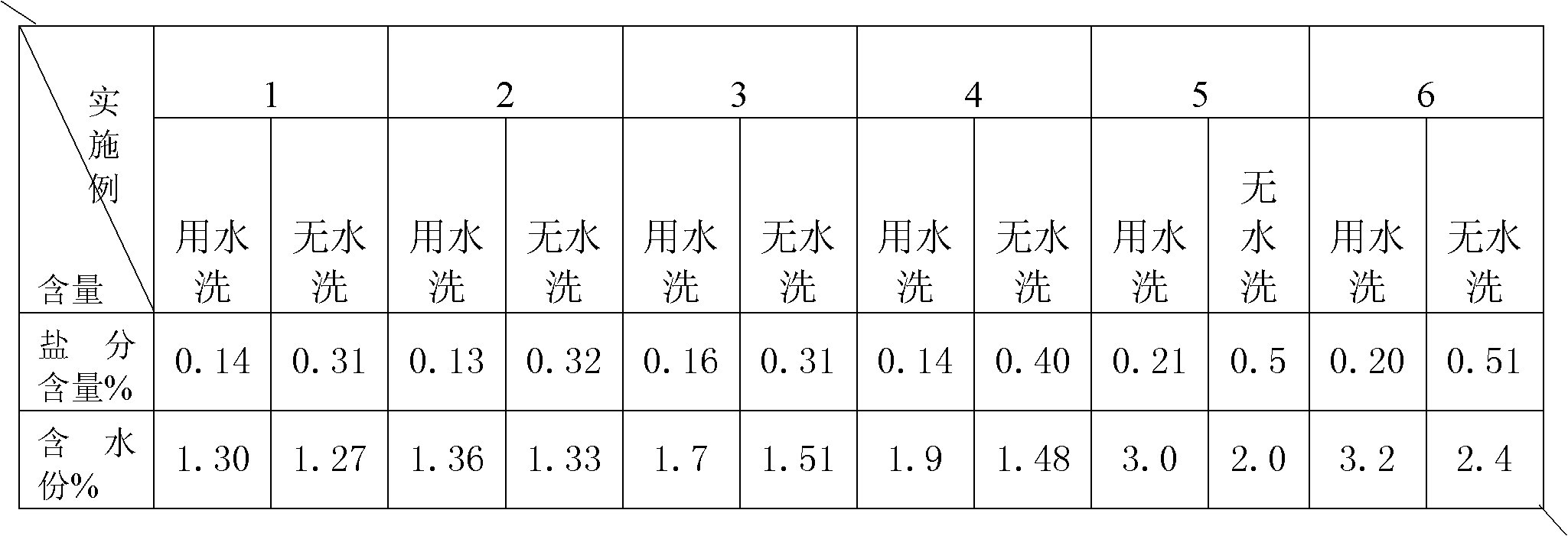

Embodiment 1

[0015] Control the salt concentration in the heavy soda ash mother liquor to 60 g / L, and when the crystallized sodium carbonate monohydrate crystal slurry enters the centrifuge for solid-liquid separation, add washing water to remove part of the salt and impurities in the sodium carbonate monohydrate filter cake , the amount of washing water to wash the filter cake of sodium carbonate monohydrate is 47kg / t 重质纯碱 .

Embodiment 2

[0017] Control the salt concentration in the heavy soda ash mother liquor to 150 g / l, and when the crystallized sodium carbonate monohydrate crystal slurry enters the centrifuge for solid-liquid separation, add washing water to remove part of the salt and impurities in the sodium carbonate monohydrate filter cake , the amount of washing water to wash the filter cake of sodium carbonate monohydrate is 110kg / t 重质纯碱 .

Embodiment 3

[0019] Control the salt concentration in the heavy soda ash mother liquor to 80 g / L, and when the crystallized sodium carbonate monohydrate crystal slurry enters the centrifuge for solid-liquid separation, add washing water to remove part of the salt and impurities in the sodium carbonate monohydrate filter cake , the amount of washing water to wash the filter cake of sodium carbonate monohydrate is 60kg / t 重质纯碱 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com