Metro motor connecting soft cable and production method thereof

A technology of motor leads and flexible cables, applied in the direction of insulated cables, flexible cables, cable/conductor manufacturing, etc., can solve the problems affecting the safe operation of subways, poor flame retardancy and oil resistance, etc., to reduce transmission and improve oil resistance Performance, the effect of reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Example 1: A production method of a flexible cable for a subway motor lead, the steps are as follows:

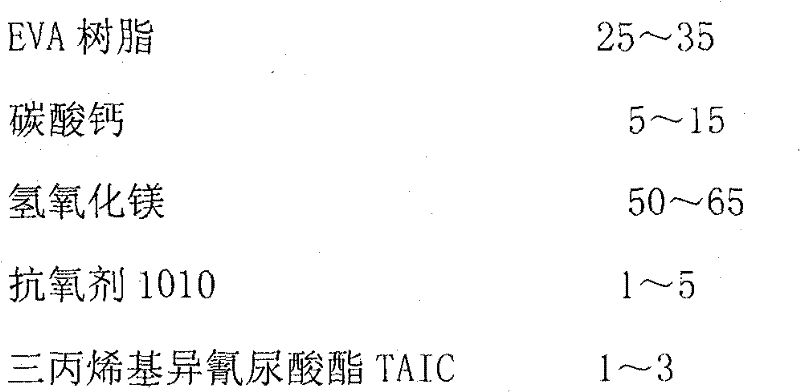

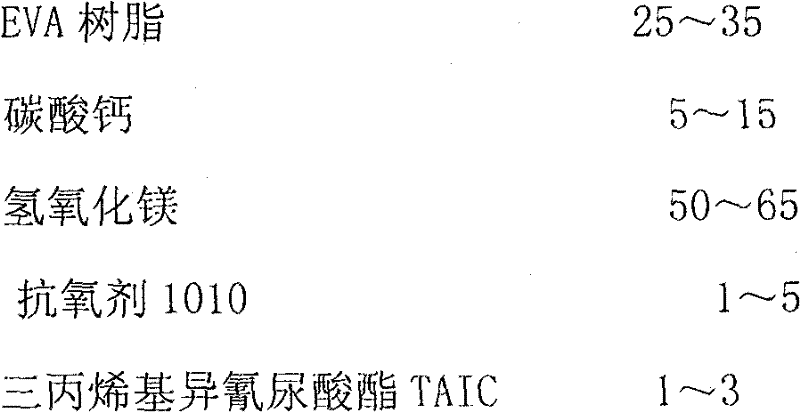

[0027] (1), 0.58KgEVA resin, 0.24Kg fineness are 800 meshes of calcium carbonate, 1.1Kg magnesium hydroxide, 0.04Kg antioxidant 1010 and 0.04Kg tripropenyl isocyanurate TAIC mix and carry out granulation, make The plasticization of each component is uniform, and the polyolefin insulation material is obtained;

[0028] (2), will be made by 1026 Φ 0.25mm tinned copper wires and the cross-sectional area is the conductor of 50mm Leading into the extrusion device through the tension device, while the polyolefin insulating material made in the step (1) is sent to Enter the extrusion device, so that the polyolefin insulating material is extruded on the surface of the conductor, and the cable is obtained. The traction speed of the conductor is 5 m / min, and the traction tension is 320N;

[0029] (3), the irradiation accelerator applies 25KV energy, and the radiation dose is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com