Mechanical oil recovery testing platform

A technology of mechanical oil extraction and test platform, which is applied in the field of experimental research of mechanical oil extraction system, can solve problems such as the inability to meet the requirements of high-efficiency and high-reliability mechanical oil extraction equipment, the inability to guarantee the safe and efficient operation of a single device, and the inability to guarantee the safe and efficient operation of the system, etc. Achieve the effect of large stroke of pumping unit, high discharge fluid pressure, and large liquid supply and air supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

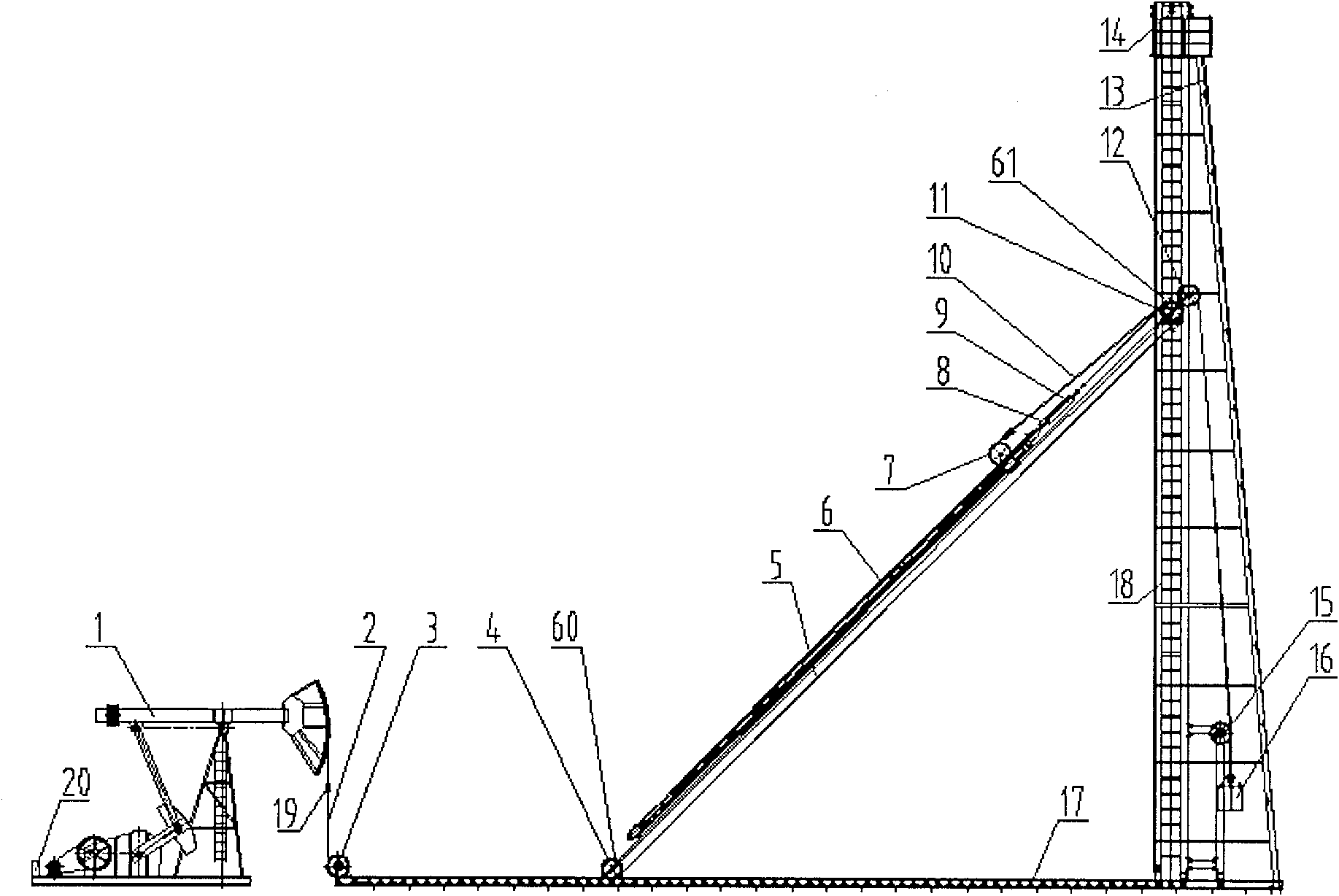

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

[0018] exist figure 1 , figure 2 Among them, a mechanical oil recovery test platform of the present invention consists of three parts: a test bench, a supply and drainage fluid system, and a measurement and control system. Simulate the working conditions and working behavior of the mechanical oil production system of directional well (horizontal well), and test the efficiency of the pumping system, the suspension point load of the pumping unit, the displacement of the suspension point, the pressure of the supply and discharge fluid, the temperature, the flow rate and other parameters, and test the Data are processed and reproduced in real time.

[0019]The test bench includes a pumping unit 1, an oil pumping steel rope 2, a rope hanger 19, fixed pulleys (3, 4, 7, 11, 12, 15), a shaft tire frame 5, a shaft assembly 6, an oil pumping Rod 8, stroke loss s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com