Inorganic flame retardant-mixed micro-surfacing pavement maintenance material

An inorganic flame retardant and micro-surfacing technology, which is applied in the field of asphalt pavement maintenance mixed materials and tunnel asphalt pavement maintenance materials, to solve fire safety problems, simple construction technology, and improve driving performance

Inactive Publication Date: 2010-11-10

NANTONG ZHONGRUN CONCRETE +1

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0022] Technical problem: The purpose of this invention is to provide a micro-surface maintenance material for pavement with the addition of inorganic flame retardants. After micro-surface maintenance treatment, the flame-retardant pavement maintenance material can solve the flame-retardant problem in the use process of tunnel asphalt pavement , so that the tunnel asphalt pavement always has a flame retardant effect during use, and the addition of inorganic flame retardants does not affect the original micro-surface construction process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

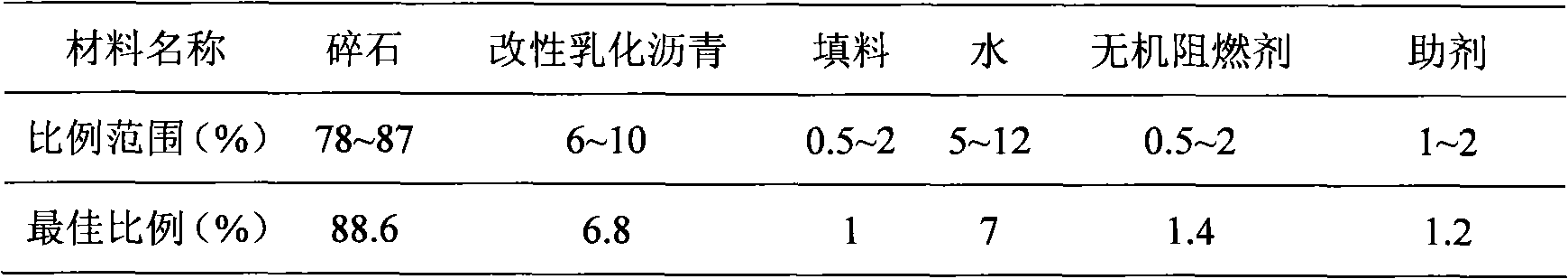

[0042] Example 1: crushed stone: modified emulsified asphalt: filler: water: inorganic flame retardant: auxiliary agent = 88.6: 6.8: 1: 7: 1.4: 1.2

example 2

[0043] Example 2: Crushed stone: modified emulsified asphalt: filler: water: inorganic flame retardant: additive = 83.3: 6.5: 1.5: 6.5: 1.2: 1

example 3

[0044] Example 3: crushed stone: modified emulsified asphalt: filler: water: inorganic flame retardant: additive = 81.4: 7: 1.8: 7.2: 1.3: 1.3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an inorganic flame retardant-mixed micro-surfacing pavement maintenance material which is a material for an asphalt pavement of a tunnel, in particular to an asphalt pavement maintenance mixing material for solving the problem of inorganic flame retardancy, belonging to the technical field of preparation of an asphalt pavement material of a road. The mixing material comprises the following components by a mixing ratio range: 78-87 percent of broken stone, 6-10 percent of modified emulsifying asphalt, 0.5-2 percent of padding, 0.5-2 percent of inorganic flame retardant, 1-2 percent of auxiliary agent and the balance of water. By applying in the micro-surfacing maintenance of the asphalt pavement of the tunnel, the inorganic flame retardant effectively improves the flame retardancy of the asphalt pavement of the tunnel in the use process under the premise of not changing all road performances of the original micro-surfacing asphalt mixing material, thereby solving the problem of fire safety of the asphalt pavement of the tunnel. The prescription not only can not influence various use performances of the original pavement but also does not improve construction difficulty, therefore, the inorganic flame retardant-mixed micro-surfacing pavement maintenance material has more favorable popularization value in the asphalt pavement maintenance of the tunnel.

Description

technical field [0001] The invention relates to a material for tunnel asphalt pavement maintenance, in particular to an asphalt pavement maintenance mixed material for solving the problem of inorganic flame retardancy, and belongs to the technical field of road asphalt pavement material manufacturing. Background technique [0002] 1. Development trend of tunnel pavement [0003] Due to the short history of building large-scale highway tunnels in my country, the research on tunnel pavement structure and materials in China is relatively weak. Most tunnel pavements use cement concrete pavement with a single structure type. On the one hand, it is because the cement concrete pavement has high strength and long service life, which is more in line with the needs of frequent construction in the tunnel, and the pavement is light in color, and the driving visibility is high; on the other hand, the fire performance of the cement concrete pavement is relatively good. , the output of hi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B26/26C04B22/06

Inventor 黄晓明许涛赵永利

Owner NANTONG ZHONGRUN CONCRETE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com