Slag cooler

A slag cooler and slag chip technology, applied in lighting and heating equipment, fluidized bed combustion equipment, combustion methods, etc., can solve the problems of polluted environment, burnout of slag cooler, small flow rate, etc., to reduce environmental pollution, The effect of prolonging the service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

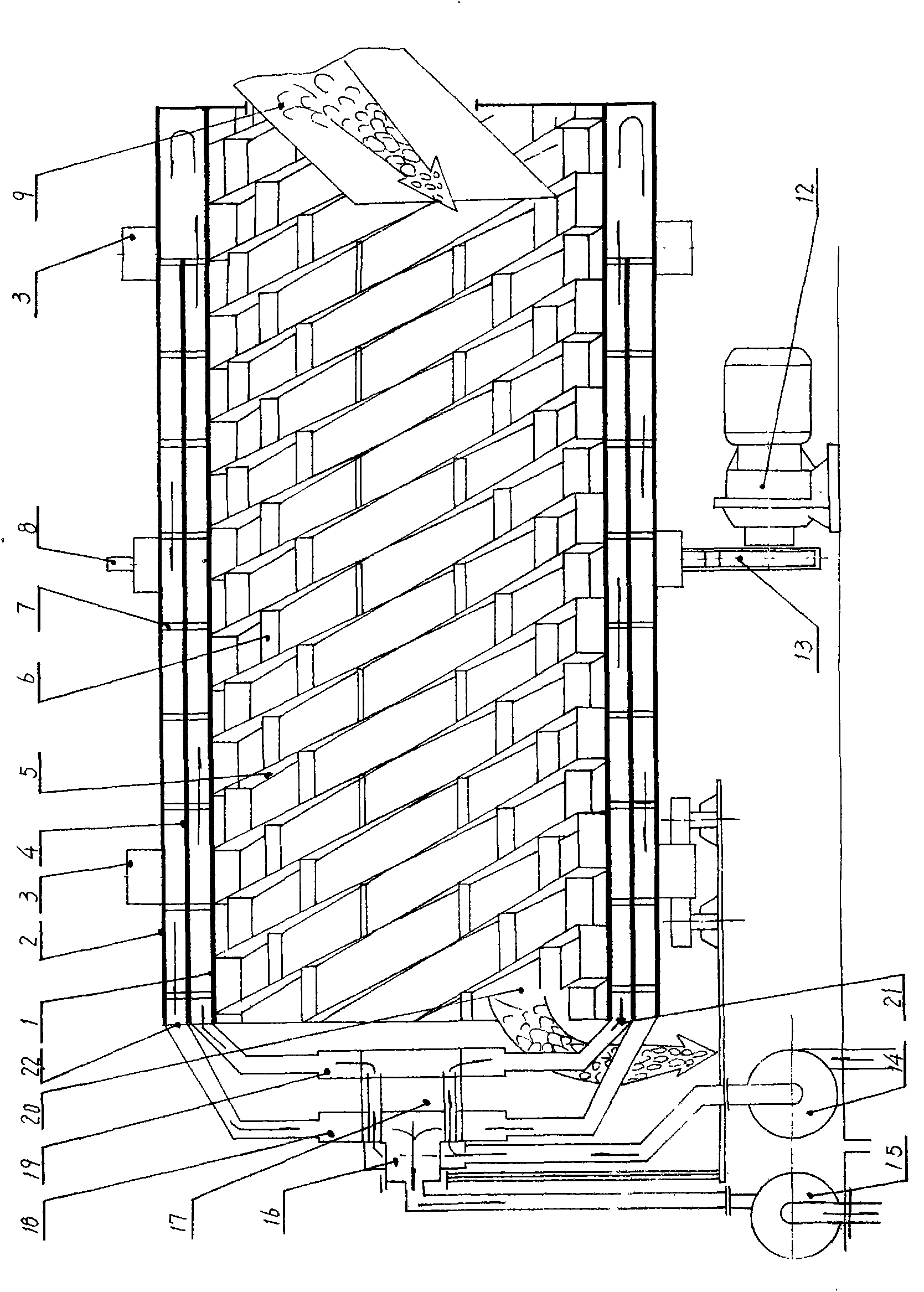

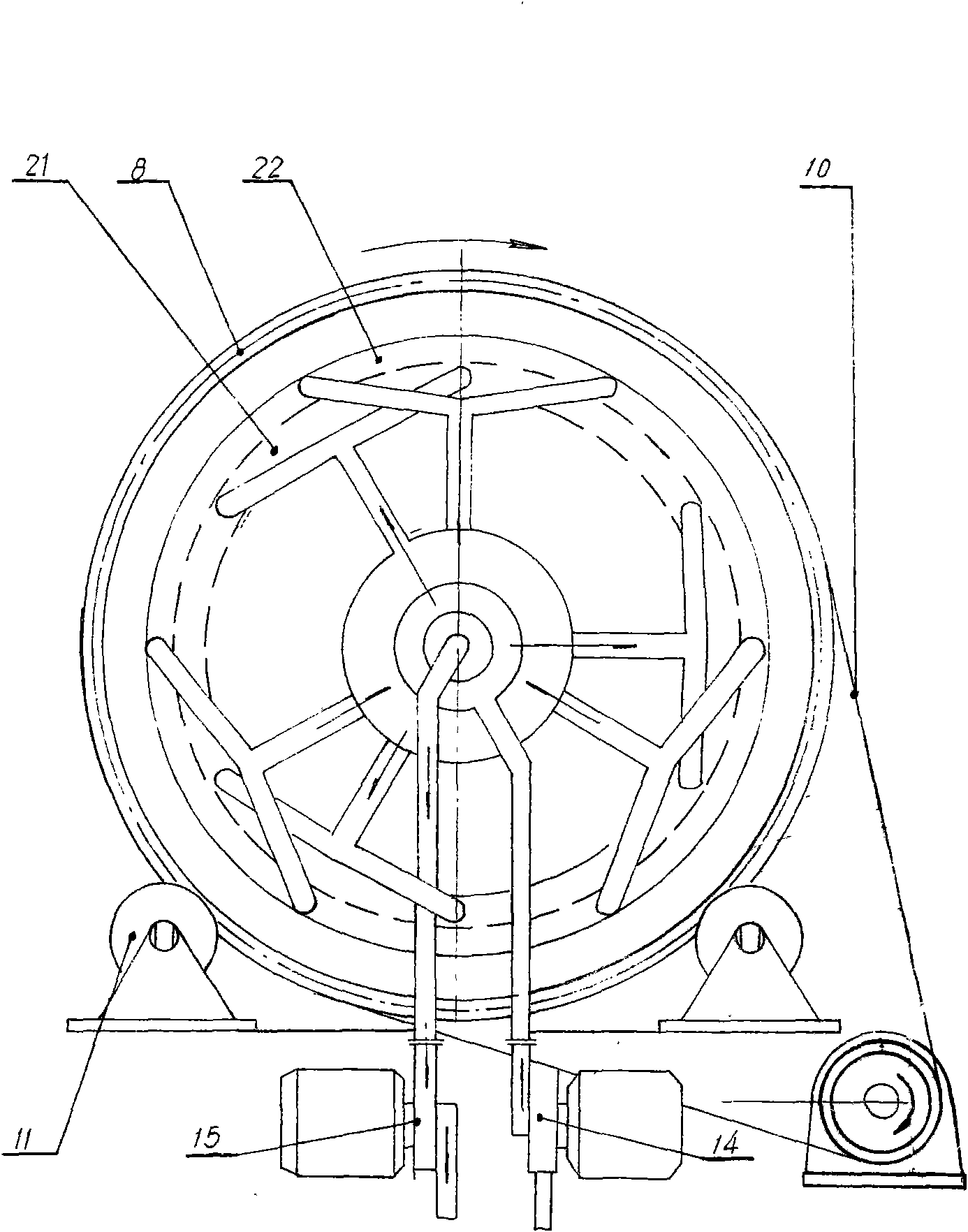

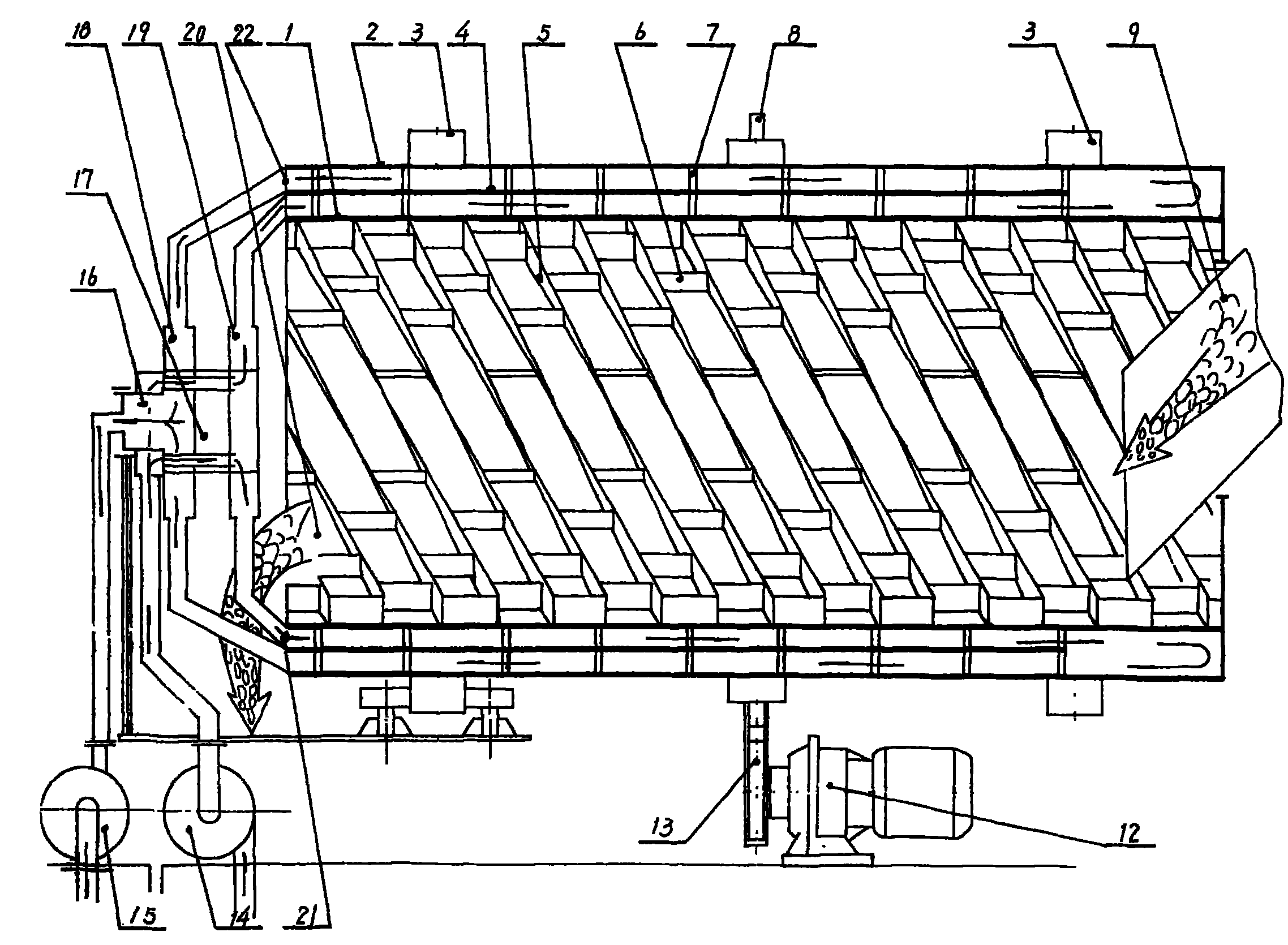

[0008] refer to figure 1 , 2 , the cylindrical barrel body includes an inner barrel wall 1 and an outer barrel wall 2, a cooling water interlayer is formed between the inner and outer barrel walls, and slag guide pieces 5 arranged in a spiral shape are welded on the inner side of the inner barrel wall, and the adjacent spiral Several partitions 6 are welded on the inner cylinder wall between the arranged slag guide sheets, and several small grids are formed between the partition boards and the slag guide sheets. There is a slag inlet 9 at one end of the cylinder body, and a slag discharge port 20 at the other end. Two tracks 3 surrounding the barrel body are fixed on the outer wall of the barrel body, and the track is placed on the track supporting wheel 11 of the support base, and a large sprocket 8 is also installed on the outer wall, and the large sprocket is driven by the chain 10 and the reducer 12 The sprocket 13 is connected, and there is also an inlet water pump 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com