Finished product guide wheel mechanism on wire drawing machine

The technology of a guide wheel mechanism and a wire drawing machine is applied in the field of the finished guide wheel mechanism, which can solve the problems affecting the overall efficiency and low bearing capacity, and achieve the effects of good interchangeability, long service life, and increased floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

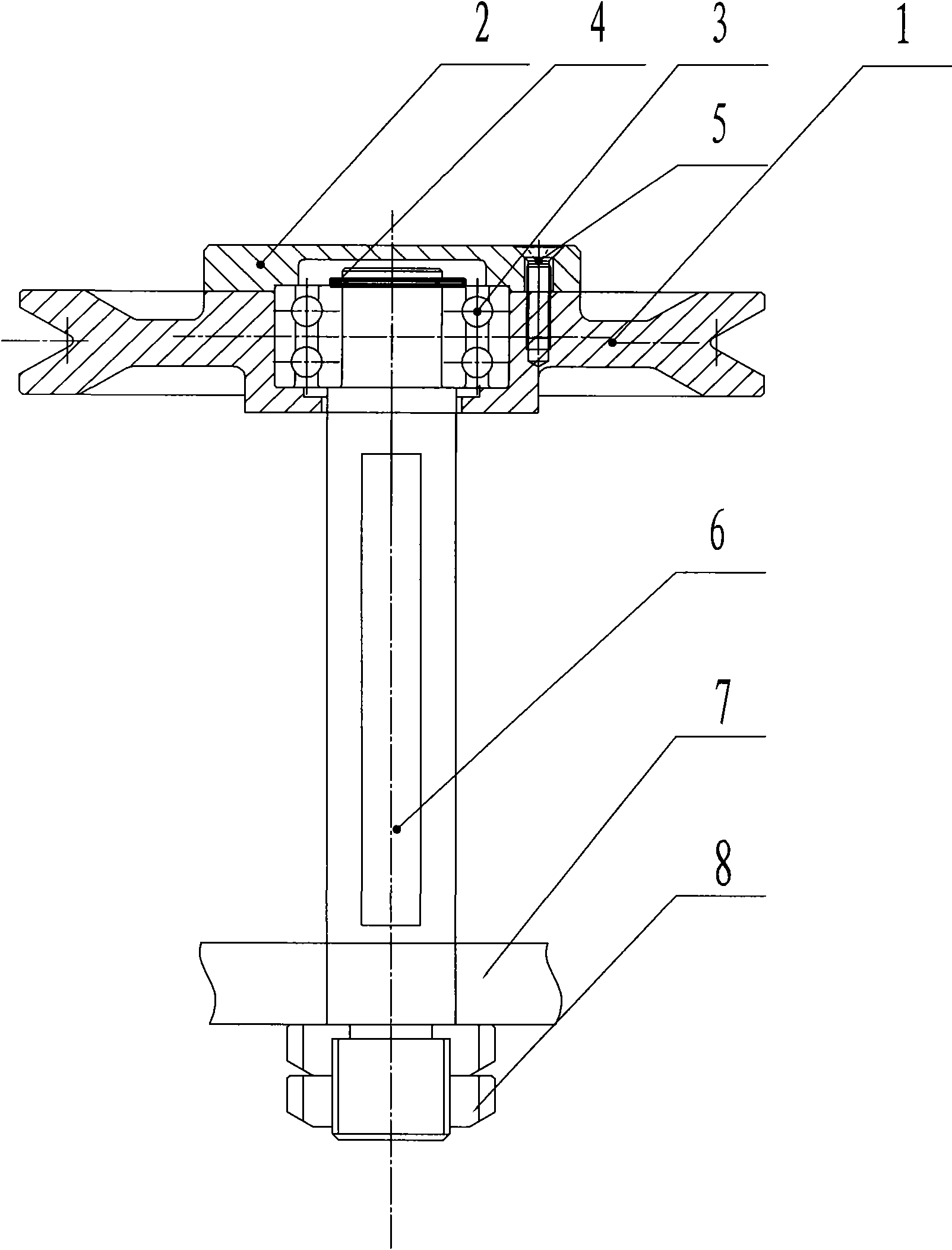

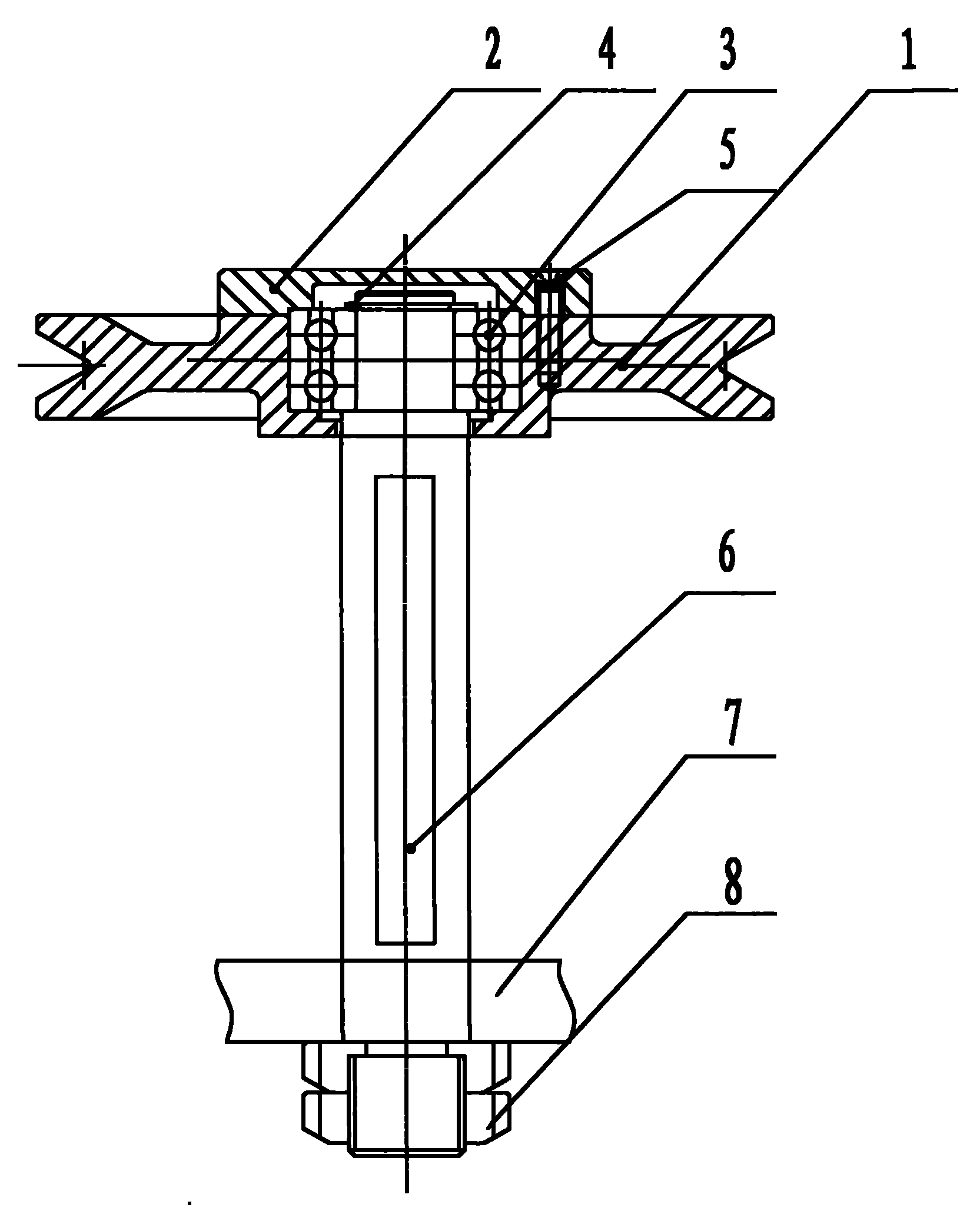

[0009] figure 1 Shown: including guide wheel 1, guide wheel cover 2, bearing 3, shaft retaining ring 4, countersunk screw 5, guide wheel shaft 6, frame 7 and round nut 8.

[0010] In the present invention, the guide wheel 1 is first fixed on the guide wheel shaft 6 with the bearing 3 and the shaft retaining ring 4, the countersunk screw 5 is used to fasten the guide wheel cover 2 and the guide wheel 1, and the guide wheel shaft 6 is installed in the mounting hole of the frame 7 Inside, lock with round nut 8.

[0011] Working principle and working process of the present invention:

[0012] The direction of the wire output from the front of the wire drawing machine and the direction of the wire feed from the rear are often not on a straight line. This problem can be solved by guiding one or more pairs of guide wheels of the present invention. The steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com