Automatic ironing device and method of clothing logos

An ironing device and clothing technology, applied to washing devices, textile decoration, sewing tools, etc., can solve problems such as poor temperature control accuracy, unsatisfactory quality and consistency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

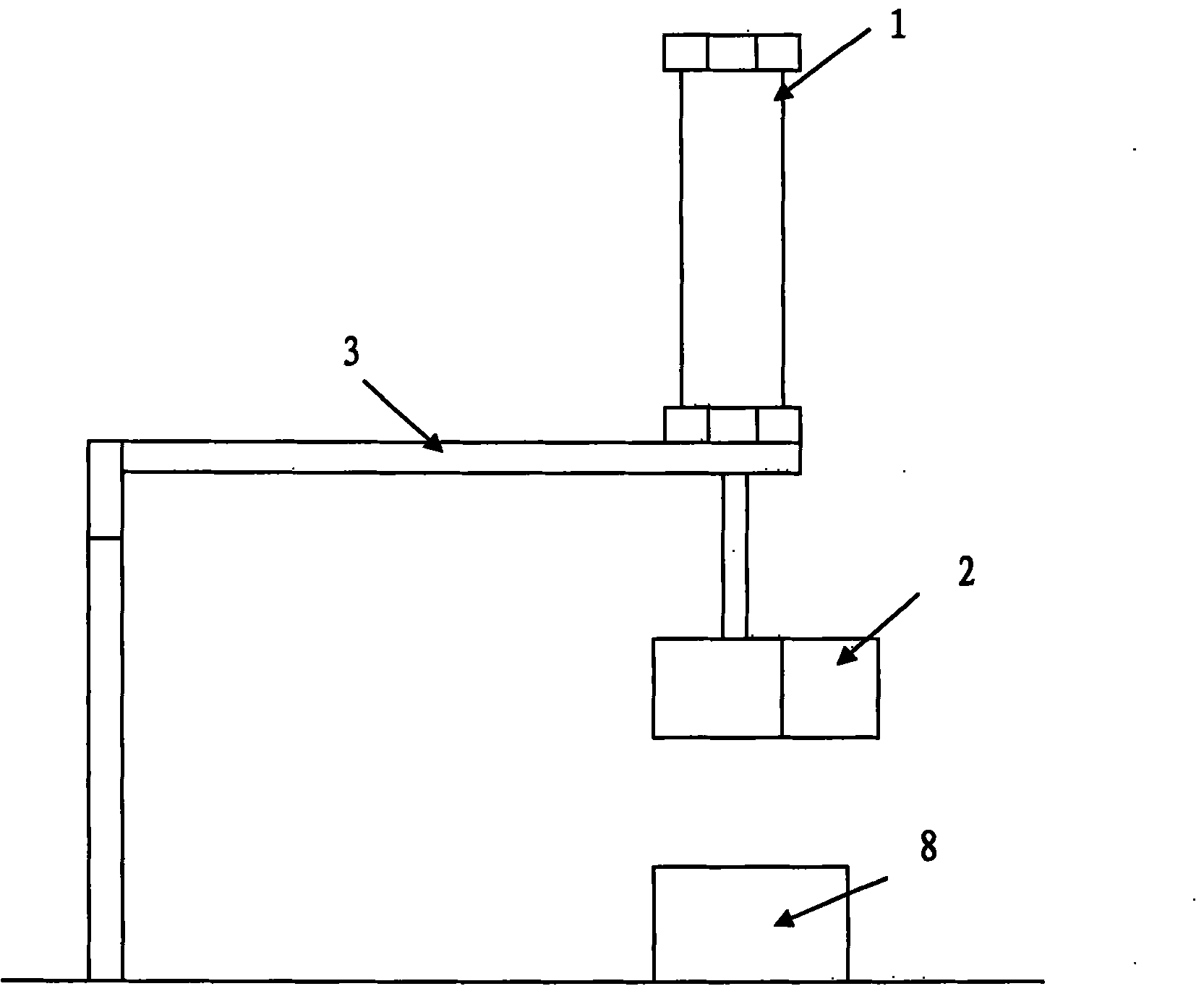

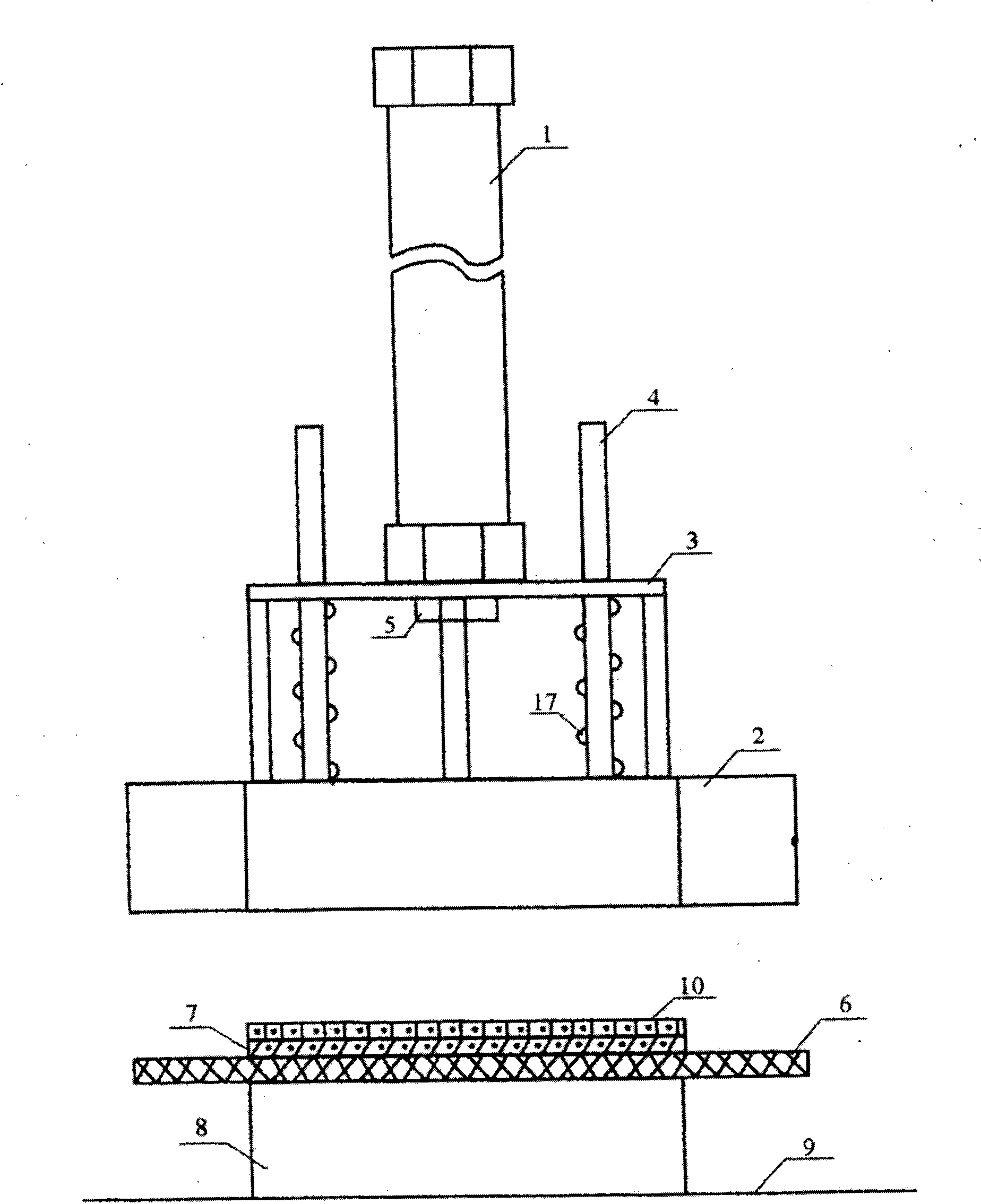

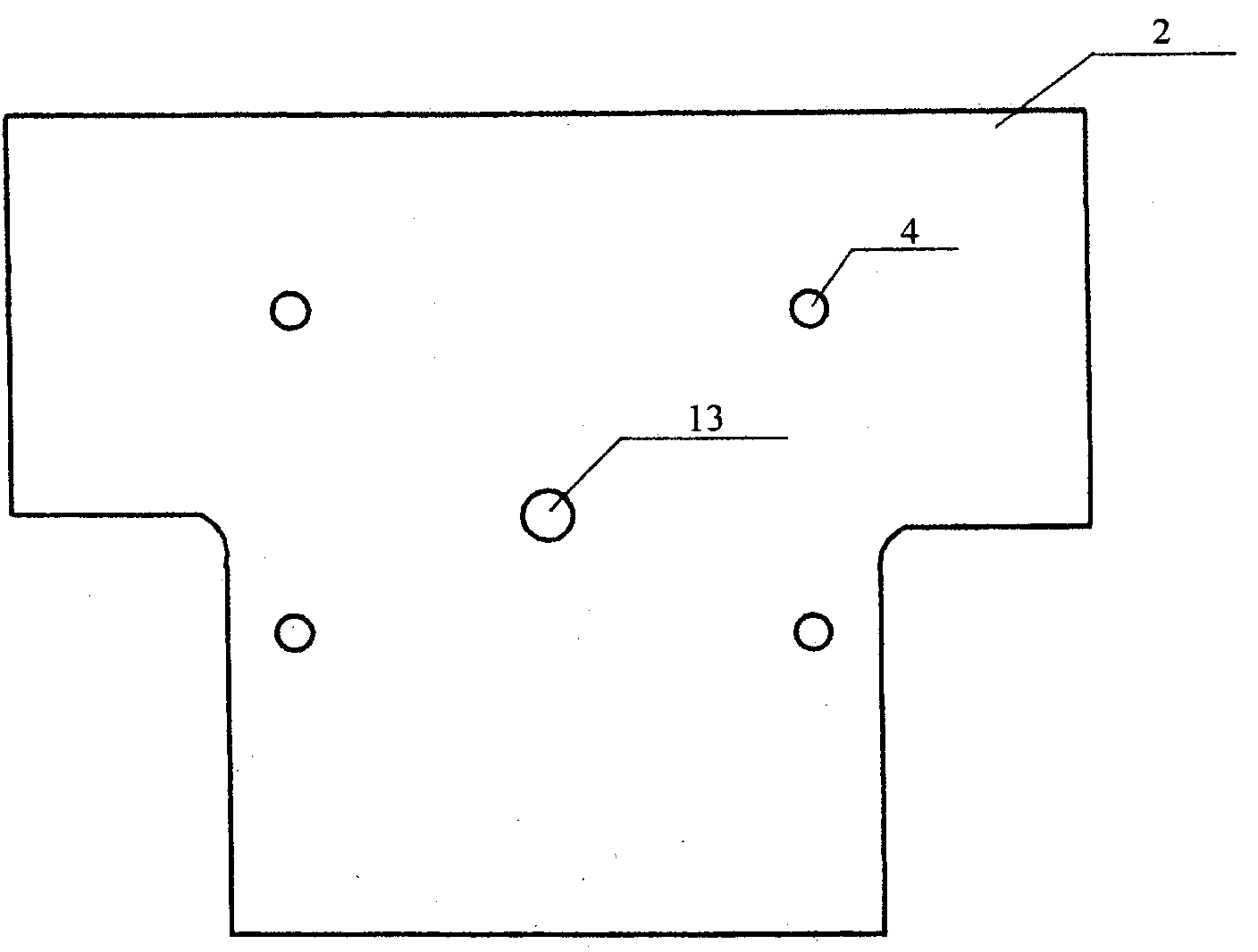

[0020] Such as Figure 1-Figure 6 As shown, the automatic ironing device for clothing marks of the present invention includes: a support, at least one cantilever 3 is horizontally arranged at the upper end of the support; The mechanism can be a cylinder 3 or an electric drive structure, etc.; the pressing plate 2 is installed at the lower end of the driving mechanism; the cushion block 8 is arranged under the pressing plate 2; wherein, electric heating is provided in the pressing plate and / or the cushion block Device 12, in order to ensure that there is no reflection on the surface of the garment after ironing, the electric heating device is preferably installed in the pad; the electric heating device can be selected according to needs, such as electric heating rods or electric heating wires.

[0021] As a further improvement of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com