Mobile framework equipment

A technology for moving formwork and equipment, which is applied in the direction of erecting/assembling bridges, formwork/formwork/working frames, bridge construction, etc., and can solve the problems of construction period, construction safety, and traffic occupation that are difficult to meet the specified requirements. The settlement of the foundation is not easy to control, the line shape of the beam body is not ideal, etc., so as to facilitate the travel of citizens, improve the overall work efficiency, and make the site civilized and concise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

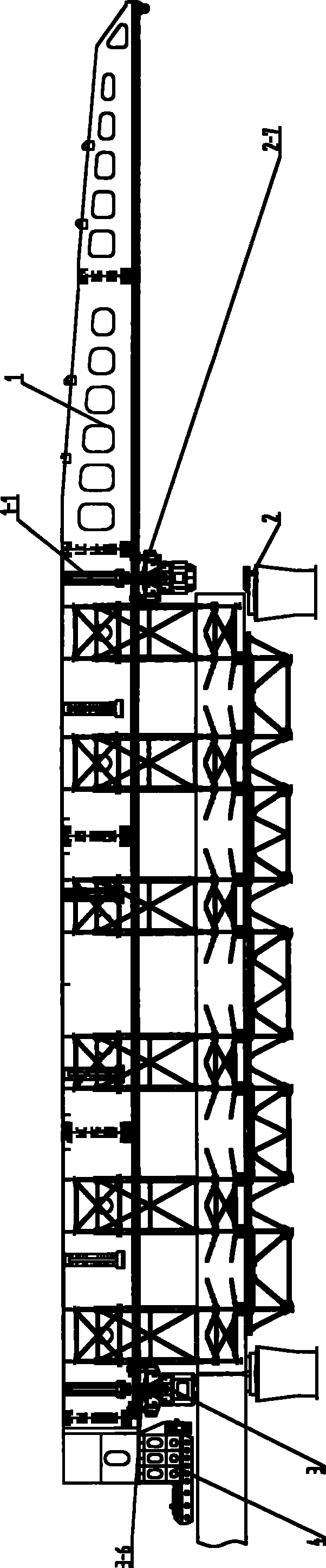

[0037] like figure 1 , 2 , 3, the present invention includes a main beam 1 and a formwork arranged at the bottom of the main beam 1, a front leg 2 is arranged at the front end of the main beam 1, and a rear leg 3 is arranged at the rear end of the main beam 1, The main beam 1 at the rear end of the rear support leg 3 is provided with a vertically moving auxiliary leg 4, and a cantilever beam 5 is hinged on both sides of the main beam 1, and a boom 6 is hinged at the ends of the cantilever beam 5 on both sides. The lower end of the boom 6 is hinged with a side formwork 9, the inner formwork 7 is hinged between the side formworks 9 on both sides, and the bottom formwork 8 is rollingly connected with the side formworks 9 on both sides.

[0038] Main beam corbels 1-1 are fixedly arranged on both sides of the main beam 1; the main beam 1 is welded by steel plates.

[0039] like Figure 4 , 5 , shown in 6, described front support leg 2 is made of hanging wheel 2-1, idler wheel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com