Supporting mechanism

A support mechanism and support device technology, which is applied in the direction of supporting machines, testing of machine/structural components, mechanical equipment, etc., can solve the problems of not being able to ensure the same center height of drill pipes, and not being able to adapt to slender rods, etc., to achieve saving Adjustment time, adjustment cost reduction, effect of simplifying adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

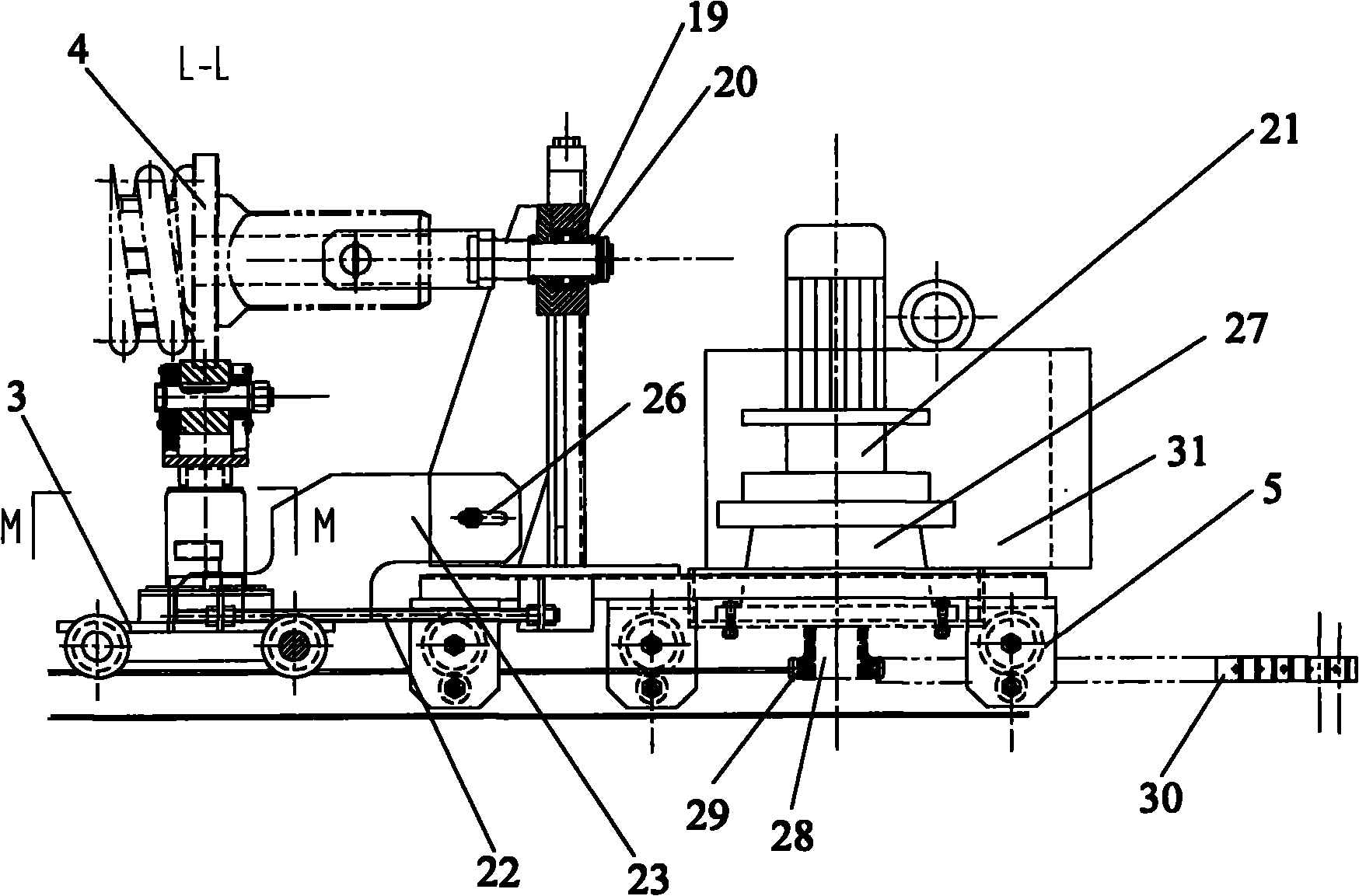

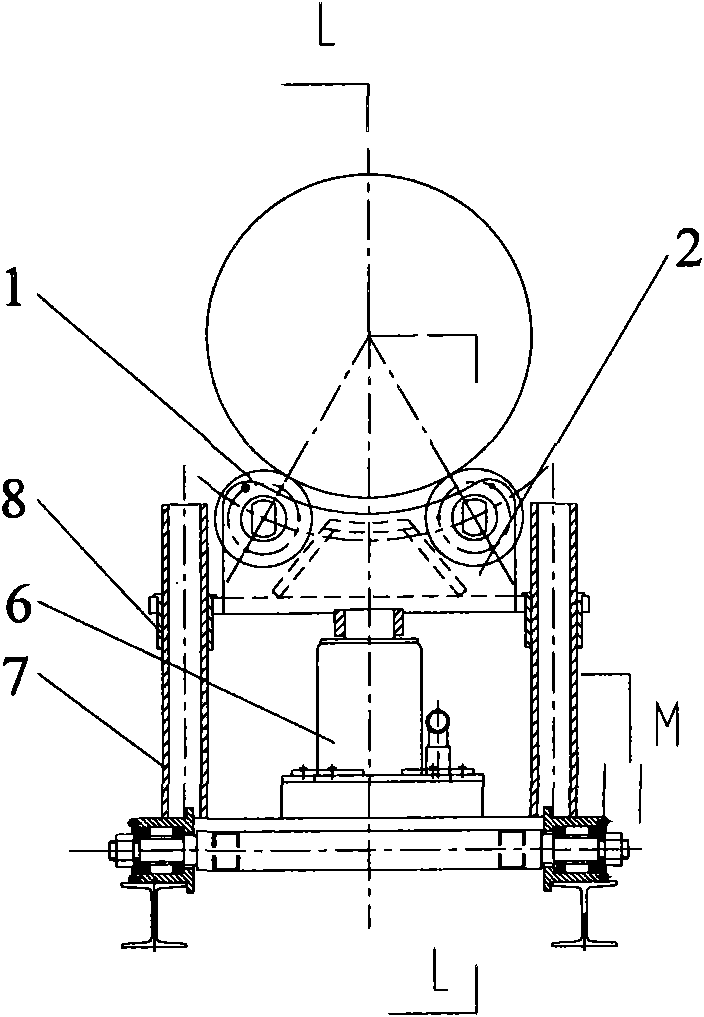

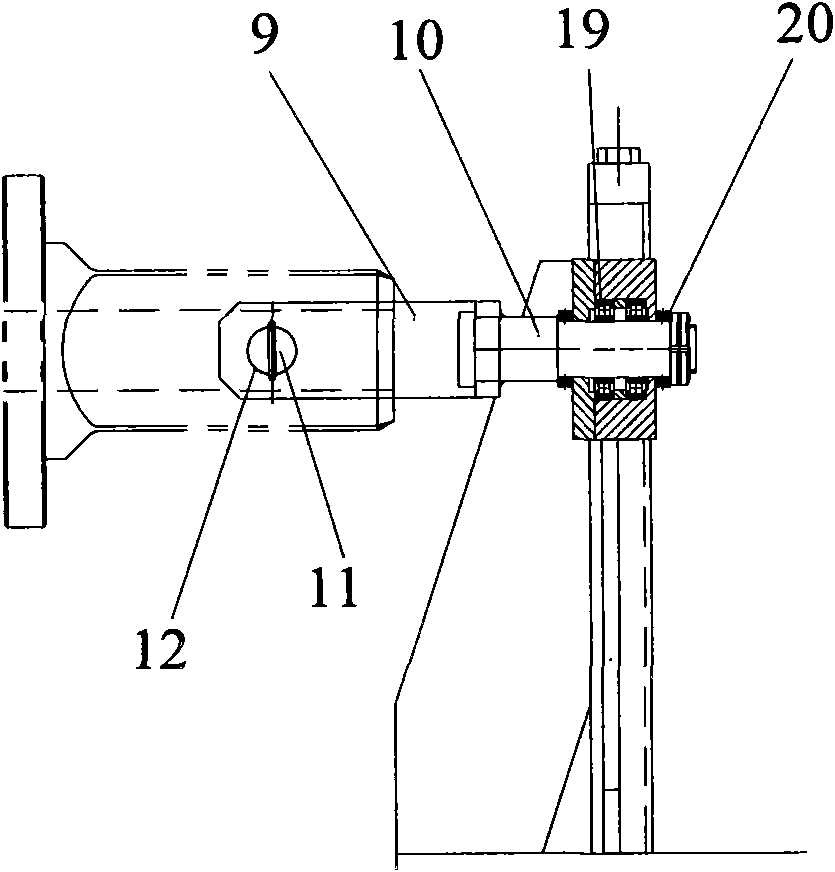

[0027]figure 1 A support mechanism according to the invention is shown, wherein the mechanism has support means and push-pull means. exist figure 1 The support device can be seen on the left side, which has: at least two supporting wheels 1, a flange 4 for openly carrying an elongated rod, wherein in a preferred embodiment of the invention, the elongated rod It is a drill pipe; the supporting roller frame 2 is used to carry the supporting roller 1; the lifting device is used to lift the supporting roller frame 2; the guiding structure is used to guide the lifting movement of the supporting roller frame 2; and it can run on the track The chassis trolley 3 is used to carry lifting equipment and guiding structures. exist figure 1 The right side of the shows the push-pull device, which has a push-pull head structure for pushing and pulling elongated rods; a push-pull head height adjustment structure for adjusting the height of the push-pull head structure; The push-pull trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com