Special drying agent for vehicle braking air passage and production method

A vehicle brake and desiccant technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve problems that affect the life of the brake system and rust on the metal surface, so as to avoid corrosion hazards and improve Adsorption capacity, long-term effective absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

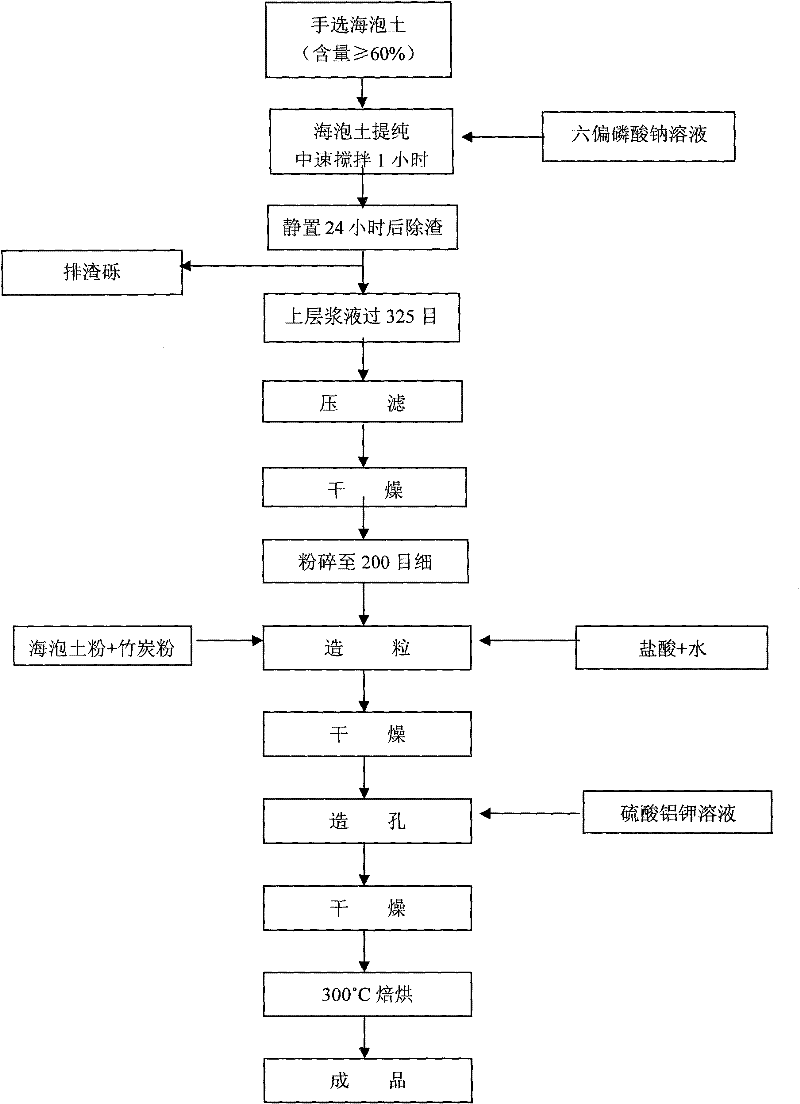

[0043] As shown in Figure 1, the production method of the special desiccant for the vehicle brake air circuit of the present embodiment is calculated in parts by weight, and the process steps include:

[0044] Step 1: add 100 parts of sepiolite into water and stir to disperse, the purity of the selected sepiolite is greater than 60%, the ratio of parts by weight of sepiolite to water is 1:2 to 1:6, and the sepiolite is mixed After the liquid was stirred at a medium speed for one hour, an aqueous solution containing 1-5 parts of sodium hexametaphosphate was added;

[0045] Step 2: Let the mixed liquid settle for 24 hours, and then remove the lower layer of debris;

[0046] Step 3: Pass the obtained sepiolite slurry through a 325-mesh sieve;

[0047] Step 4: filter the sepiolite slurry through a filter press, and dry the solid obtained after the filter press;

[0048] Step 5: pulverize the dried product to 200 mesh;

[0049] Step 6: mix and granulate the sepiolite powder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com