Drawer sliding rail

A drawer and slide rail technology, applied in drawers, furniture parts, household appliances, etc., can solve the problems of inconvenient access, loud noise, easy shaking, etc., and achieve the effect of unaffected stability and multi-functional expansion of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

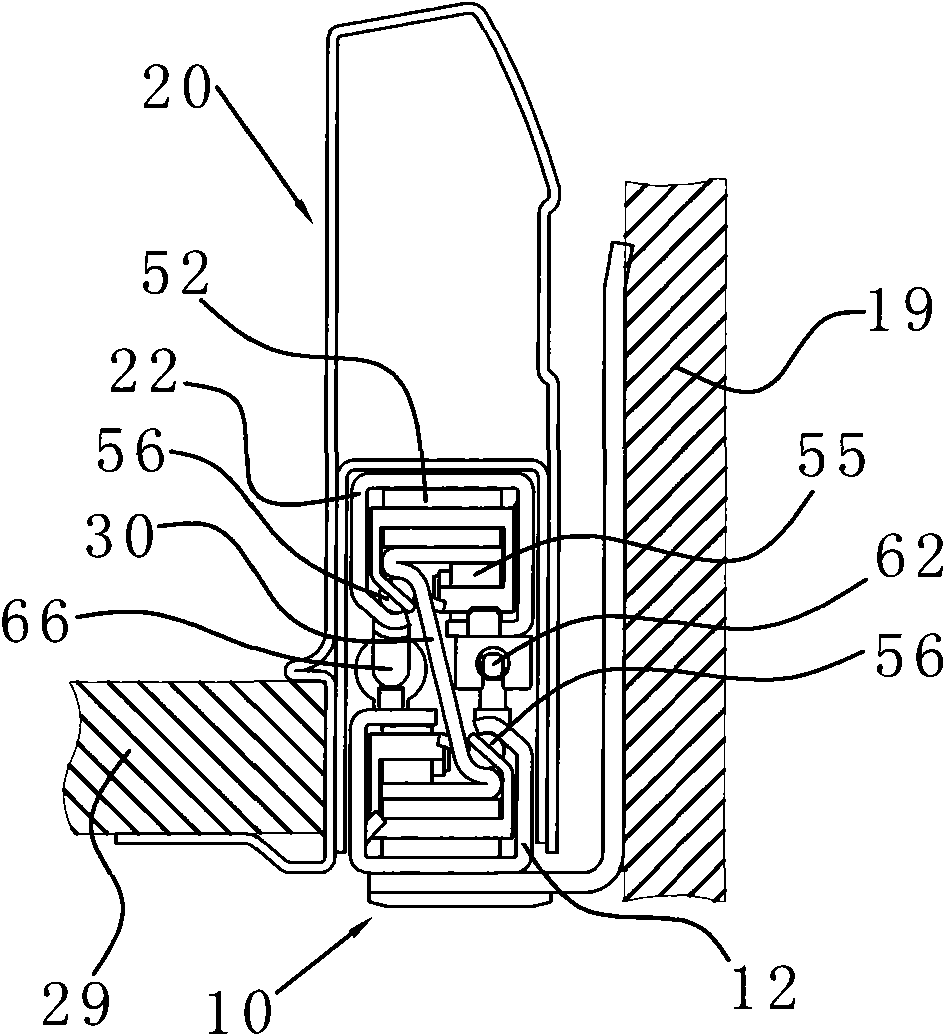

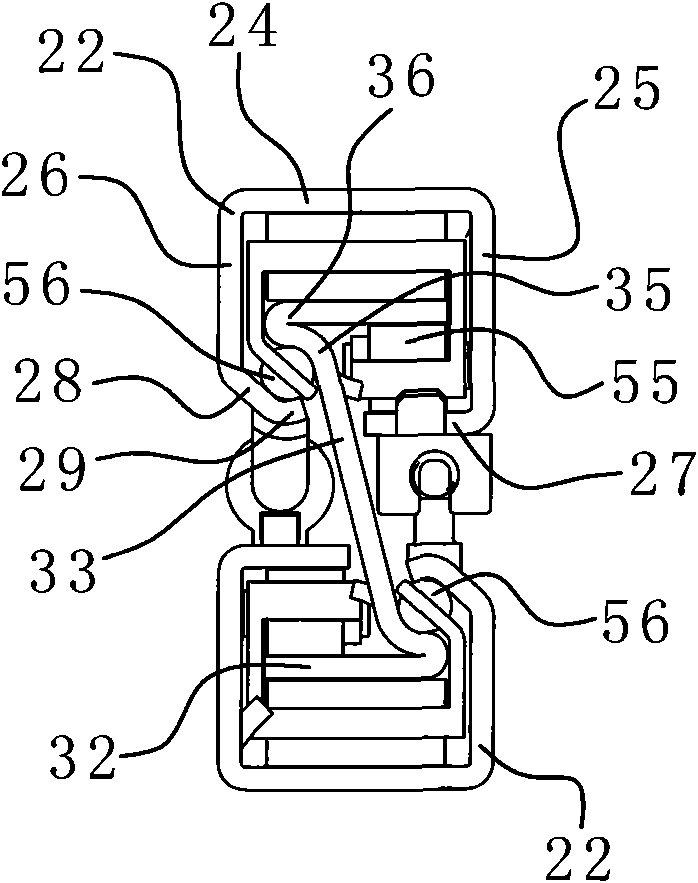

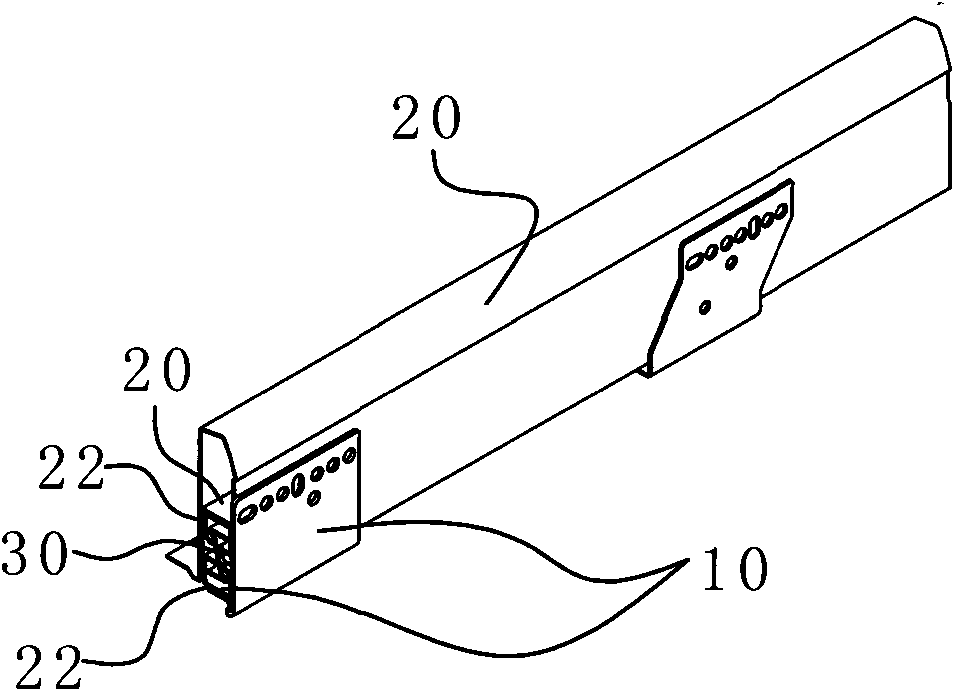

[0026] refer to figure 1 , figure 2 , image 3 , a drawer slide rail for installing a drawer in a drawer cabinet according to the present invention, which includes a fixed rail 10 fixed to the drawer cabinet body, a moving rail 20 fixed to the drawer, and a fixed rail 10 arranged between the moving rail 10 and the fixed rail. The middle rail 30 between the rails 20.

[0027] The above-mentioned middle rail 30 includes two horizontal plates 32 and an inclined plate 33 connecting the two horizontal plates, forming a Z-shaped cross section. Both the moving rail 20 and the fixed rail 10 have a rail sleeve 22 slidably sleeved on the horizontal plate 32 . Wherein the two horizontal plates 32 can be parallel to each other, more preferably, the horizontal plates are arranged horizontally, so that the installation of the slide rails is simpler and more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com