Sensing system and method

A sensing system and sensing element technology, applied in the field of sensing systems, can solve problems such as unsatisfactory technology, real-time sensors, impractical and time-consuming continuous monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

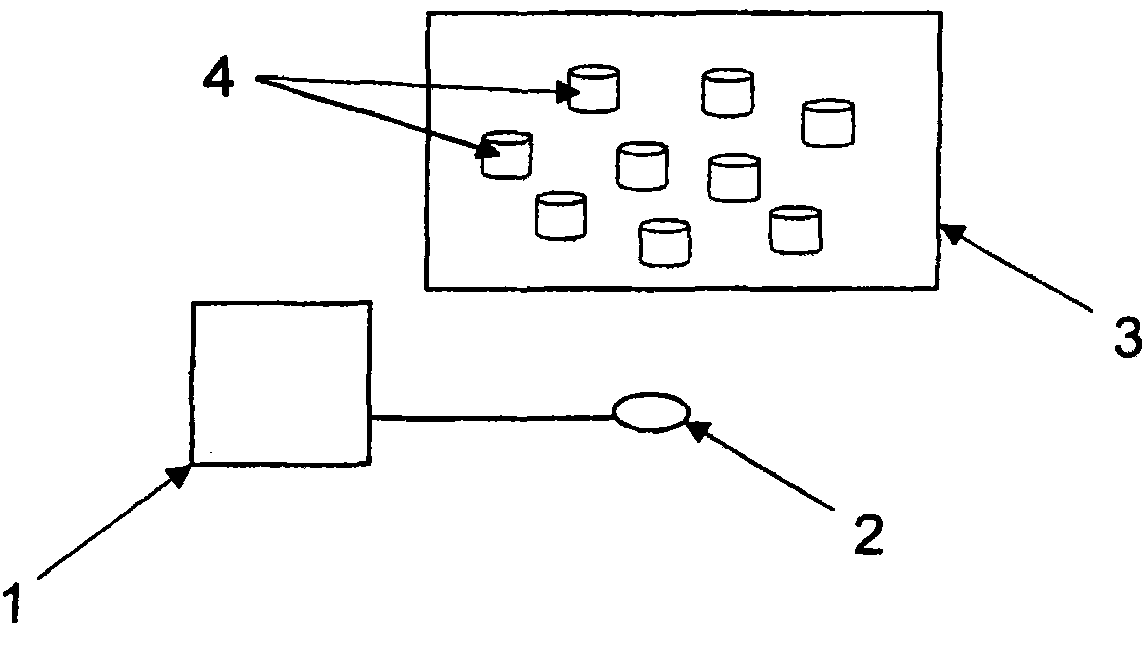

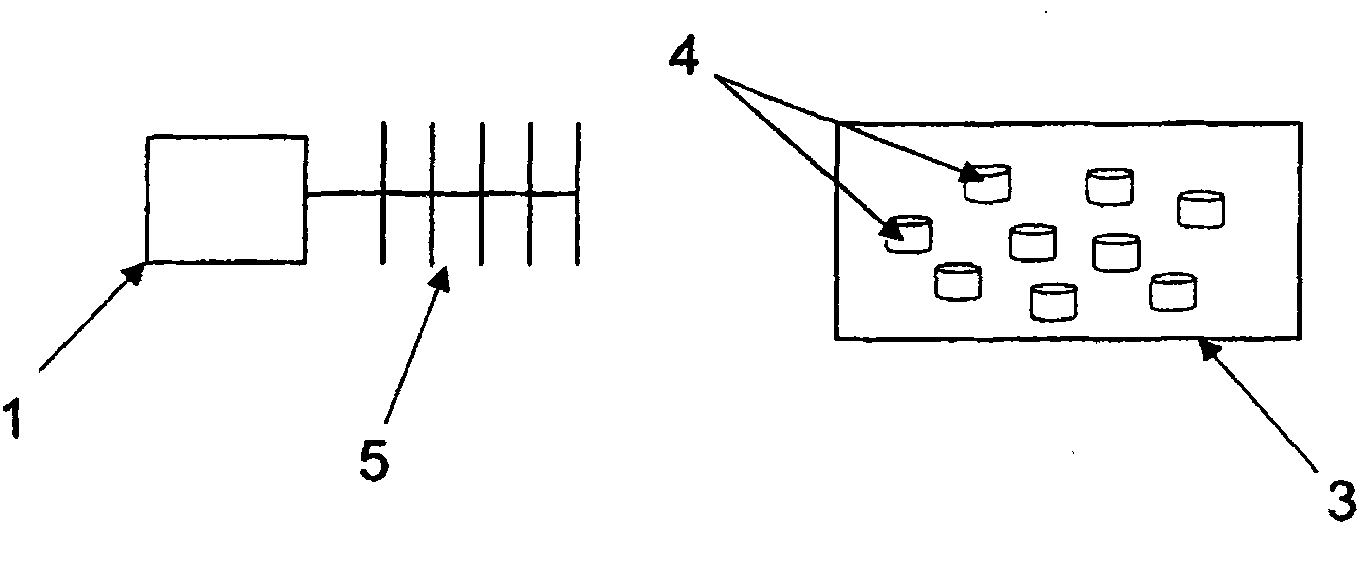

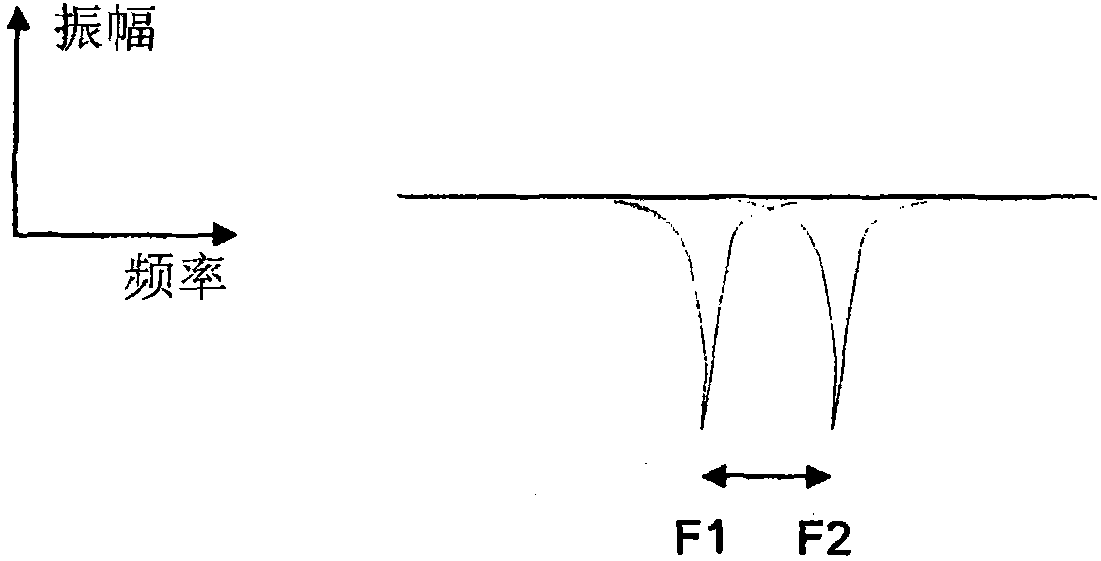

[0029] see figure 1 , showing a schematic diagram of a wireless transceiver 1 with an antenna 2 . A part of the material 3 (for example, a polymer material) has a matrix structure in which a plurality of sensing elements 4 are embedded such that the sensing elements 4 are dispersed within the matrix material 3 and covered by the matrix material 3 around. The sensing element 4 has electron distribution and / or transport properties that change in response to changes in the physical or chemical properties of the material. This behavior results in a change in a radio frequency (RF) signal (eg a microwave signal) transmitted from the transceiver 1 via the antenna 2 to interrogate the matrix material 3 , so that the change in the material can be determined from the received signal. In this way, the sensing element 4 allows non-invasive, intrinsic sensing of changes in the properties of the material.

[0030] The radio transceiver 1 is constructed to generate a modulated radio freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com