Method for performance evaluation and failure diagnosis of coke oven multi-loop control system

A control system and multi-loop technology, applied in comprehensive factory control, electrical program control, electrical test/monitoring, etc., can solve problems such as performance degradation, product output reduction, and operating cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

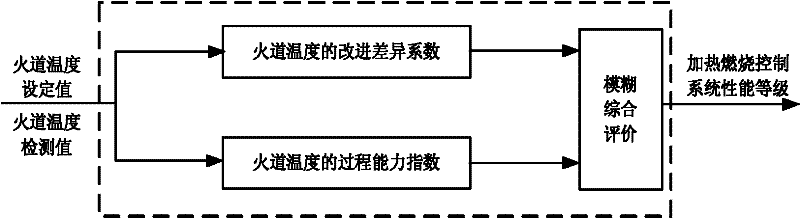

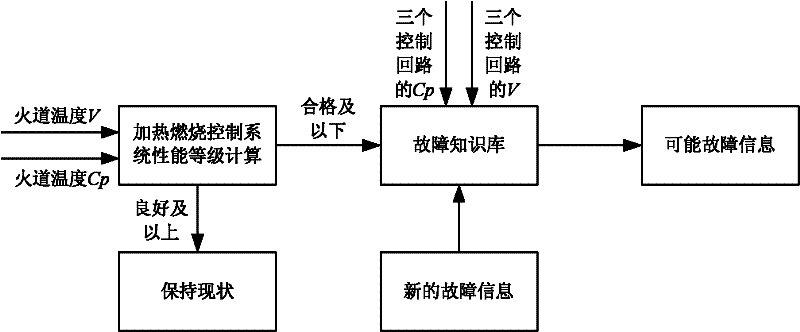

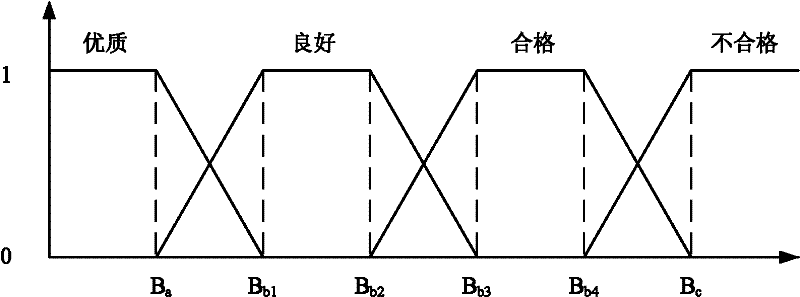

[0040] For the performance evaluation and fault diagnosis of the multi-loop control system for the heating and combustion process of the coke oven, it is first necessary to establish the indicators needed for the evaluation. These indicators are also the index of the fault source search during the fault diagnosis. Two indicators of capability index.

[0041] 1. In order to reflect the fitting degree between the detected value of the flue temperature and the set value, the improved coefficient of difference is defined as the performance index, and the formula is as follows:

[0042] V = Σ i = 1 N ( Y t - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com