Separated assembly type gate

A fence gate and assembled technology, which is applied in the direction of gates/doors, etc., can solve the problems of packaging and transportation inconvenience, cost increase, and affect the appearance of the door, and achieve the effect of ornamental, neat appearance, and change of connection mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

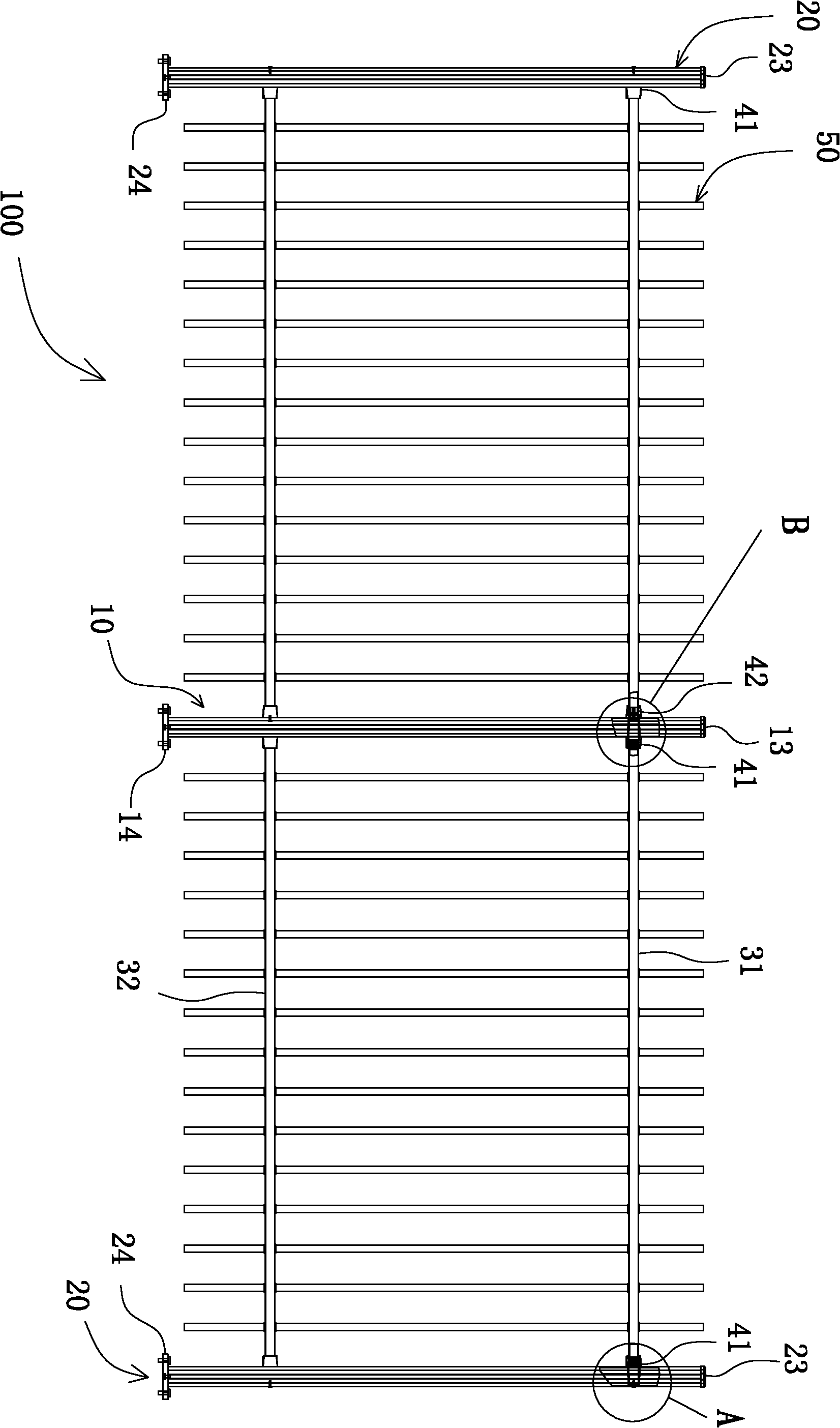

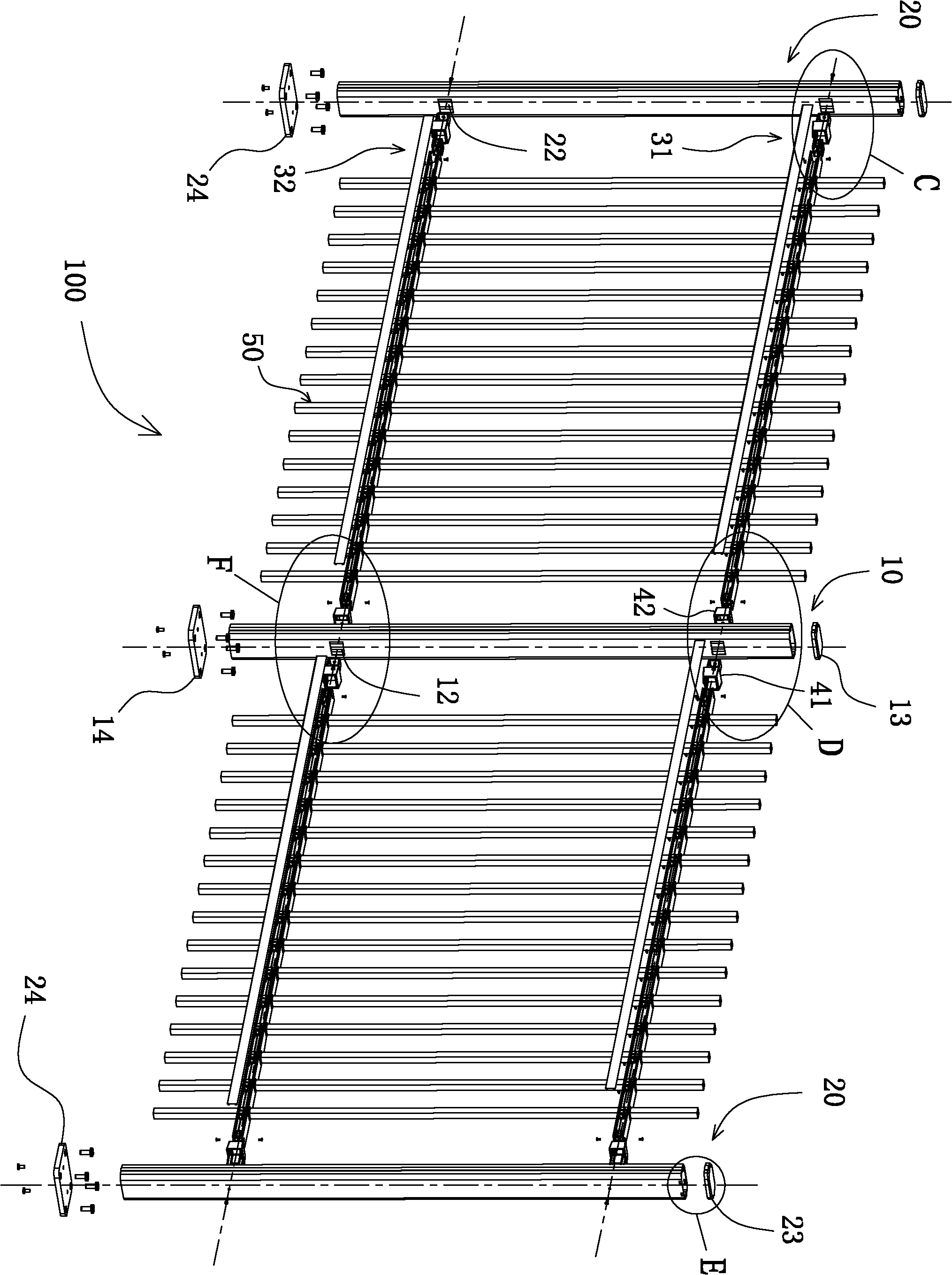

[0028] see figure 1 , figure 2 , The split-assembled fence gate 100 of the present invention includes a main column 10 , a side column 20 , an upper beam 31 , a lower beam 32 , a first connecting piece 41 , a second connecting piece 42 and a railing 50 .

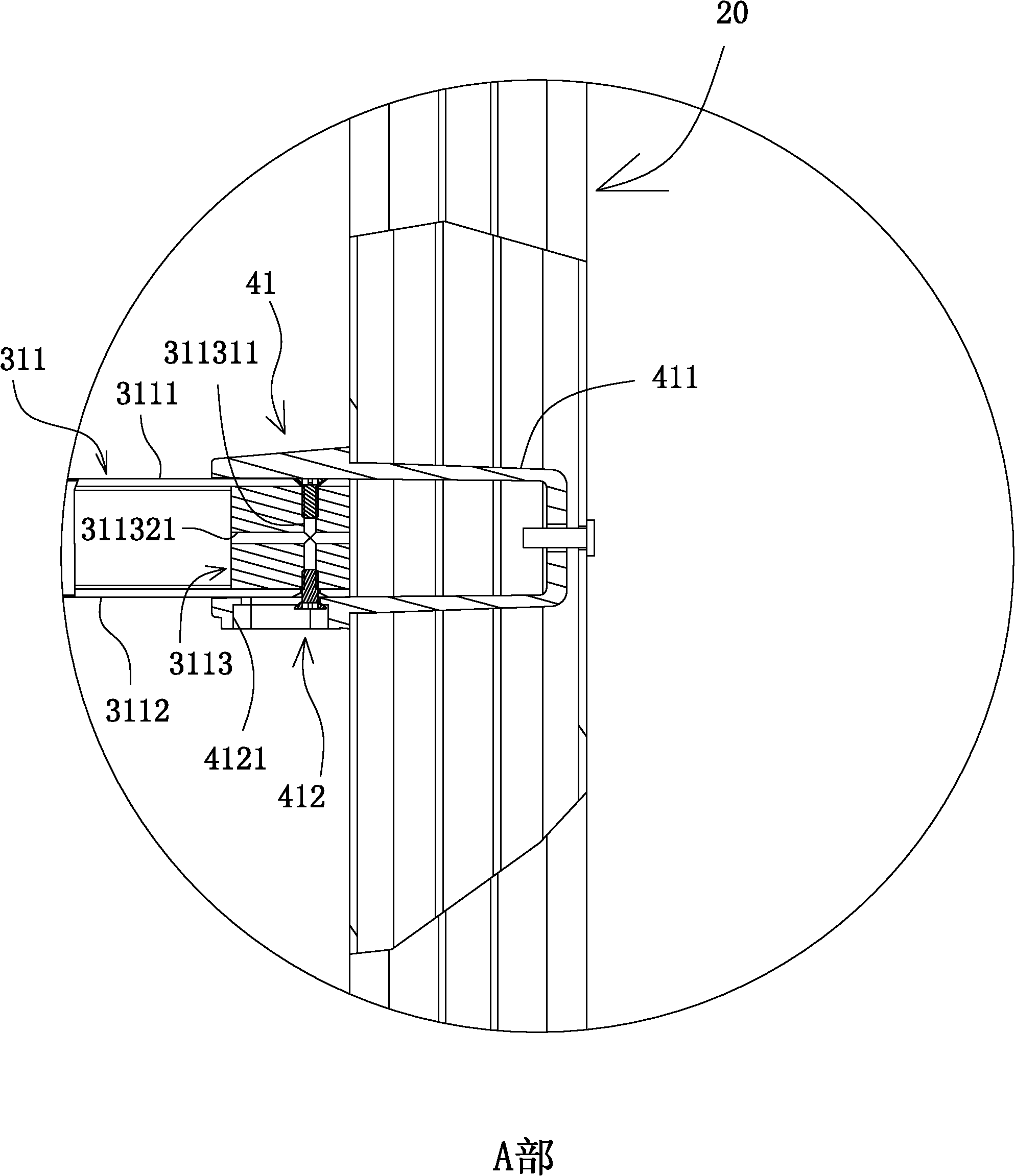

[0029] like Figure 4 , Image 6 As shown, the main column 10 is an empty metal pipe. According to the length of the fence gate, the main column 10 can be one or more. In this embodiment, a main column is arranged in the center of the fence gate. The center of the front and rear tube walls of the column 10 is symmetrically provided with two axial holes 11 extending from the upper end to the lower end. Holes, whose outwardly protruding semi-cylindrical surfaces play a decorative role. The proximal end of the upper and lower ends of the main column is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com