Engine base device of backwashing water purifier

A technology for washing water and machine bases, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Timing recoil and other problems to achieve the effect of preventing secondary pollution, stable quality and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

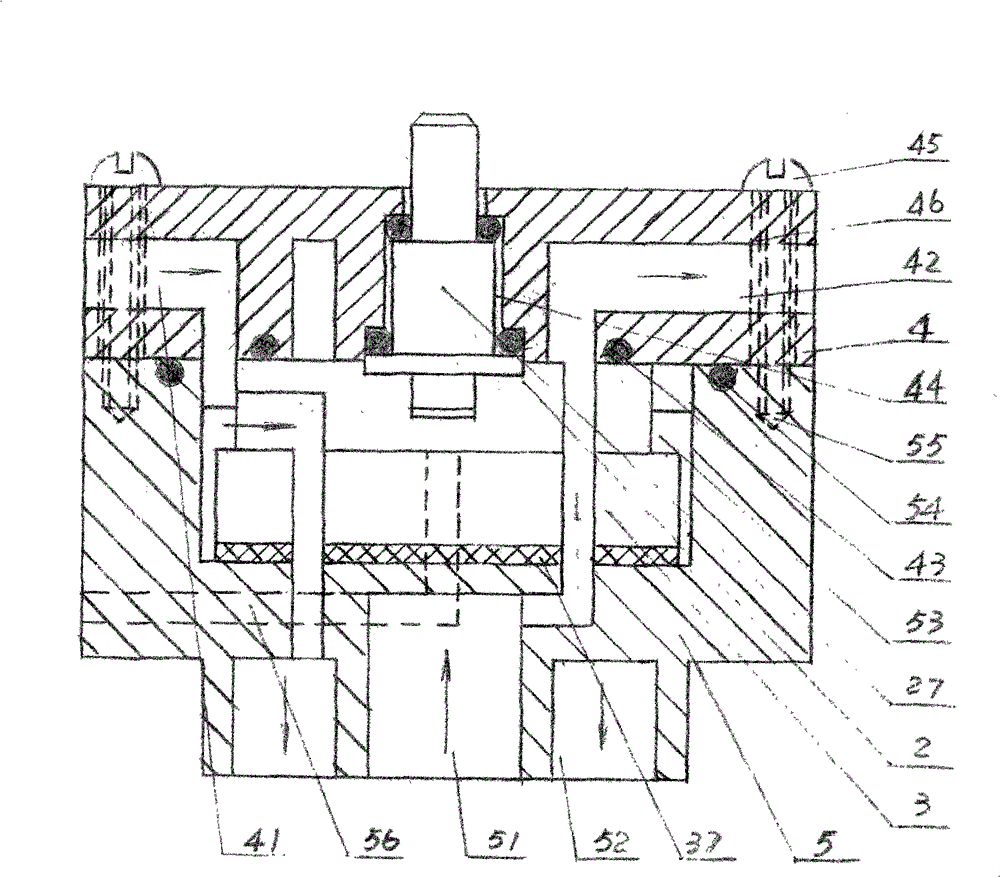

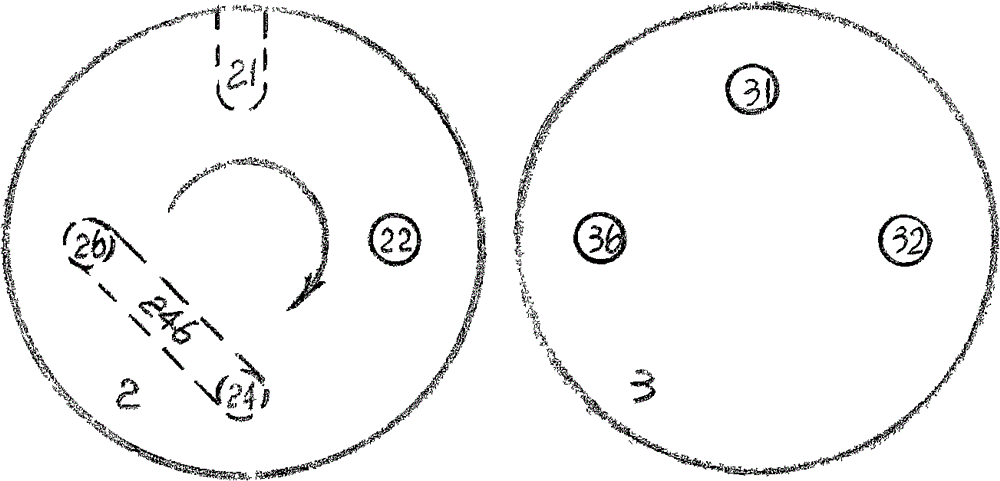

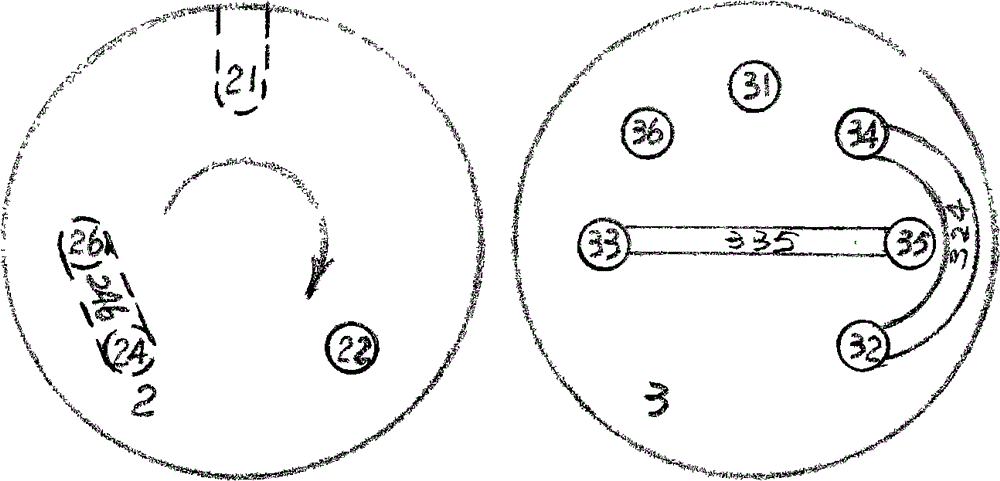

[0034] figure 1 , 2 It is the best embodiment of the present invention. It adopts the combination structure mode of rotating disc water inlet, double disc quarter position combination structure water switch, inner cavity 5 and cover 4, and is used in conjunction with the filter element of the two outlets. figure 1 Among them, the sealing gasket 37 with the water inlet and outlet is located on the bottom surface of the inner cavity 5 of the machine base, and is inserted together with the fixed plate 3 with the limiting protrusion 53 to perform radial and circumferential limiting. Each water port on the two is respectively connected with the water port on the bottom surface of the inner cavity correspondingly. The rotating disc 2 is in contact with the fixed disc 3 to form a sealed switching interface. The lower end of the manual shaft assembly 27 is inserted into the rotating disk 2 to rotate together, and the upper part is placed in the small cavity 44 through a seal, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com